Smart Solutions for Using Liquid Fertilizer in Greenhouse Tomatoes

In modern greenhouse farming, using liquid fertilizer has become one of the most important daily tasks. For a 20-mu tomato greenhouse, keeping plants healthy depends not only on what nutrients are used but also on how they are mixed, handled, and delivered. That’s why growers place great importance on equipment that can keep nutrient water clean, well-mixed, and steady. From the moment the water enters the greenhouse to the moment the tomatoes receive it at their roots, every link affects the final harvest. In facilities that rely heavily on using liquid fertilizer, this chain of equipment becomes the backbone of the entire production system.

The goal of this article is simple: to clearly introduce the machines required for a complete nutrient-solution system in a 20-mu tomato greenhouse. No complex formulas or scientific terminology—just a clear look at what equipment matters, what each piece does, and why it is needed. Whether you are planning a new greenhouse, improving an existing one, or simply curious about how commercial tomato farms operate, this overview offers a straightforward and readable guide.

Before using liquid fertilizer, growers need clean water as the foundation of every nutrient batch. Even small impurities may cause clogging or uneven feeding later. For a 20-mu tomato greenhouse, the basic water-preparation setup usually includes:

A main water tank that stores enough water for daily irrigation

A simple dual-filter to keep out sand, dust, and small particles

This is not complicated equipment, but without it, the entire process of using liquid fertilizer would face constant blockages and inconsistent flow. Clean water keeps everything smooth and reduces maintenance work later.

Once the water is ready, the next key step is dissolving fertilizers. Tomatoes need different nutrients at different growth stages, and these fertilizers must be mixed thoroughly to avoid sediment or uneven concentration.

A greenhouse of this size usually uses:

Stirrers that keep the fertilizers moving

Small tanks for special nutrients that are added in smaller amounts

None of this equipment is difficult to operate, but each tank must be big enough to prepare the daily amount of solution a 20-mu greenhouse needs. When using liquid fertilizer, growers rely on these machines to keep the nutrient water stable and evenly blended from morning to night.

After the fertilizers are dissolved, they are kept in storage tanks. These tanks prevent the nutrient solution from settling or becoming too warm. Although they look simple—just closed containers with slow-moving stirrers—they are essential for large-scale tomato operations.

Good storage equipment helps avoid:

Separation of nutrients

Sudden changes in nutrient strength

Waste caused by spoiled solution

When using liquid fertilizer several times per day, growers need these storage tanks to keep the mixture consistent from one irrigation cycle to the next.

If there is one machine that defines the entire process, it is the fertigation machine. This is the device that takes concentrated fertilizer from the storage tanks, mixes it with clean water, and sends it out to the plants. In a 20-mu greenhouse, an automatic fertigation machine brings several benefits:

It keeps the nutrient strength stable

It adjusts the mix for young or mature tomato plants

It allows growers to change settings easily

Without a good fertigation machine, using liquid fertilizer becomes guesswork. With one, the process becomes stable and predictable, which is exactly what tomatoes need for uniform growth and high-quality fruit.

A fertigation machine cannot work without reliable pumps. Pumps push the nutrient solution through long rows of tomatoes from one end of the greenhouse to the other. In a 20-mu greenhouse, growers usually install:

A main pump that delivers most of the flow

A backup pump in case of breakdown

When using liquid fertilizer many times per day, pumps must run quietly, smoothly, and without pressure drops. A sudden loss of pressure can lead to uneven feeding or overwatering in some rows.

The greenhouse is divided into different growing zones, and nutrient solution needs to reach each zone without losing pressure. The pipeline system includes:

Main pipes connected to the fertigation machine

Branch pipes that serve different rows

Small valves that can open or close flow to each area

These pipes are the “roads” for using liquid fertilizer throughout the greenhouse. With well-designed pipes, growers can water one area at a time or adjust how much each area receives based on plant needs.

The last stop of the nutrient journey is the tomato plant itself. To keep roots healthy and fruits uniform, most growers use drip irrigation lines. These thin tubes deliver a small, steady amount of nutrient water right at the base of each plant.

Good drip lines are important because:

They help avoid waste

They reduce the chance of root diseases

They keep nutrient levels steady every day

When using liquid fertilizer, these lines ensure that every plant—hundreds or even thousands—gets exactly the same amount.

Even in systems designed for easy operation, growers still need basic monitoring tools to check whether everything is running correctly. A typical setup includes:

A meter that shows how much water is flowing

A meter that checks nutrient strength

A small screen or panel that shows system status

These tools help growers avoid problems such as weak nutrient water, clogged lines, or sudden pressure changes. In a greenhouse that depends on using liquid fertilizer, regular checking is part of daily routine.

A greenhouse of this size waters and feeds its tomatoes many times every day. If any piece of equipment fails—whether it is a pump, a pipe, or a mixing tank—the plants may suffer quickly. Bad nutrient water can lead to:

Uneven fruit size

Slow growth

Wasted fertilizer

Extra labor

Higher maintenance costs

Reliable equipment reduces these risks and keeps the entire greenhouse running smoothly.

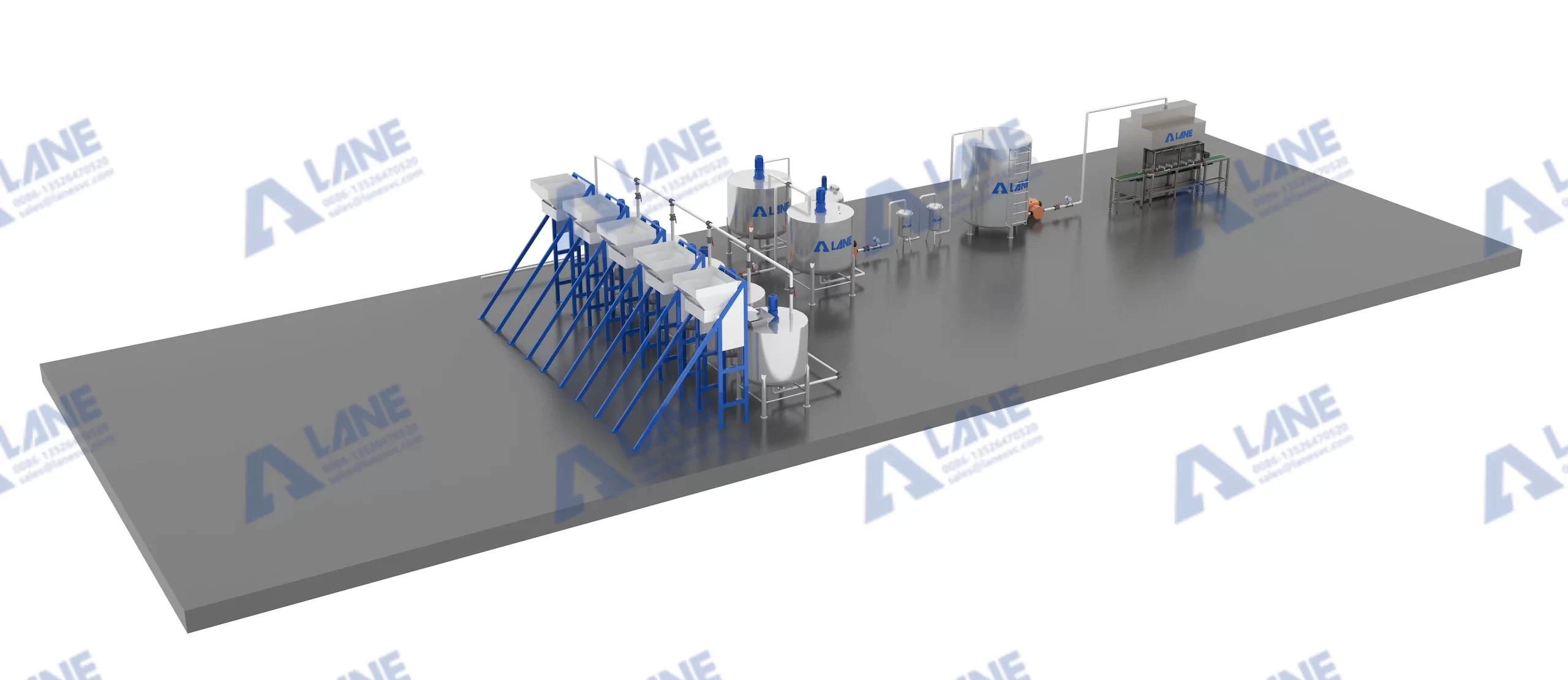

Lane Company has supplied fertilizer-related equipment for more than twenty years, giving them solid experience in greenhouse and fertilizer-production projects. Instead of offering only individual machines, they design complete systems that match the size and needs of each customer. Their engineers help plan the layout, choose the equipment, and install it on site.

All machines are produced under strict quality standards, which gives growers confidence in long-term use. Lane also provides help after installation, including maintenance guidance and equipment upgrades. For greenhouses that rely on using liquid fertilizer every day, having a dependable supplier like Lane reduces stress and keeps production stable.

For a 20-mu tomato greenhouse, using liquid fertilizer requires a chain of equipment that prepares clean water, mixes nutrients, stores the solution safely, pumps it throughout the greenhouse, and delivers it to each plant. When each part works well, tomatoes grow evenly, fruits develop better, and daily operations become simpler.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Leave a Comment

LANE has more than 500 successful cases and is committed to providing customers with first-class solutions, high-end machinery and equipment, and one-stop pre-sales, sales and after-sales comprehensive customer service.