Unlocking Sustainable Agriculture: Seaweed Extract Liquid Fertilizer Production Line

In the world of organic farming and sustainable agriculture, seaweed extract liquid fertilizer production line has gained immense popularity. Known for its rich content of micronutrients, growth hormones, and bioactive compounds, seaweed extract is an excellent natural alternative to synthetic fertilizers. The seaweed extract liquid fertilizer production line offers a streamlined process for efficiently producing high-quality liquid fertilizers from seaweed, which can significantly enhance crop yields and improve soil health.

This article delves into the technology behind the seaweed extract liquid fertilizer production line, the process steps involved, key equipment, and the benefits that such a production line can bring to agricultural businesses.

Seaweed extract liquid fertilizer is derived from marine algae, primarily brown algae like Ascophyllum nodosum, which is known for its ability to promote plant growth. The extract is rich in essential plant nutrients such as nitrogen, potassium, calcium, magnesium, and iron, as well as organic growth stimulants like cytokinins and auxins. These bioactive compounds help plants grow healthier, stronger, and more resistant to stress.

The production of seaweed extract fertilizer involves a specialized process that extracts these valuable nutrients from seaweed, turning them into a highly concentrated liquid form suitable for direct application to crops.

1. Seaweed Harvesting and Pre-Processing

The first step in the production of seaweed extract liquid fertilizer is the collection and pre-processing of the raw seaweed. Typically, seaweed is harvested from the ocean, cleaned of impurities, and then cut or shredded into smaller pieces for easier processing.

Washing and Grinding Equipment: Seaweed is washed to remove sand, salt, and other impurities before being processed in a vertical shaft crusher. This ensures that the seaweed is ready for extraction.

2. Extraction of Nutrients

The next step is the extraction of nutrients from the seaweed. This is typically done using a water-based extraction method that allows the water-soluble nutrients to be separated from the seaweed biomass. The extraction process can be done in different ways, such as cold extraction or enzyme-assisted extraction.

Cold Extraction Tank: A cold extraction tank is used to preserve the bioactive compounds present in the seaweed. This method ensures that the beneficial enzymes and nutrients are preserved, allowing for a high-quality liquid fertilizer to be produced.

Enzyme-Assisted Extraction System: An enzyme-assisted extraction system can be used to break down the complex carbohydrates in the seaweed, making it easier to extract valuable nutrients like vitamins, minerals, and growth hormones.

3. Filtration and Purification

Once the extraction process is complete, the next step is to filter and purify the liquid extract. This ensures that the liquid is free from any remaining seaweed particles or impurities, leaving a clean and concentrated liquid fertilizer.

Dual Filtration System: A dual filtration system is often employed to remove impurities, ensuring that the final liquid is pure and free from any solid particles. This step is crucial for maintaining the quality and consistency of the seaweed extract liquid fertilizer.

4. Concentration and Blending

After filtration, the liquid extract is usually concentrated to enhance its nutrient density. The concentration process involves evaporating some of the water content to make the final liquid fertilizer more potent.

Concentration Tank: A concentration tank is used to heat the liquid and remove excess water, leaving behind a concentrated solution of seaweed extract that contains all the essential nutrients for plant growth.

Stainless Steel Mixing Tank: Sometimes, other nutrients or additives are blended into the seaweed extract to enhance its effectiveness, such as micronutrients or humic substances. This is done using blending equipment to ensure that the final product is homogenous.

5. Packaging and Storage

Once the seaweed extract has been concentrated and blended, the final step is packaging. The liquid fertilizer is typically packaged into bottles or drums for easy storage and application.

Liquid Packaging Machine: A liquid packaging machine is used to fill bottles, drums, or tanks with the seaweed extract liquid fertilizer. These machines can fill containers accurately and quickly, reducing labor costs and ensuring consistent packaging.

Storage: After packaging, the liquid fertilizer is stored in controlled environments to maintain its quality. It should be stored in cool, dark places to prevent degradation of the nutrients.

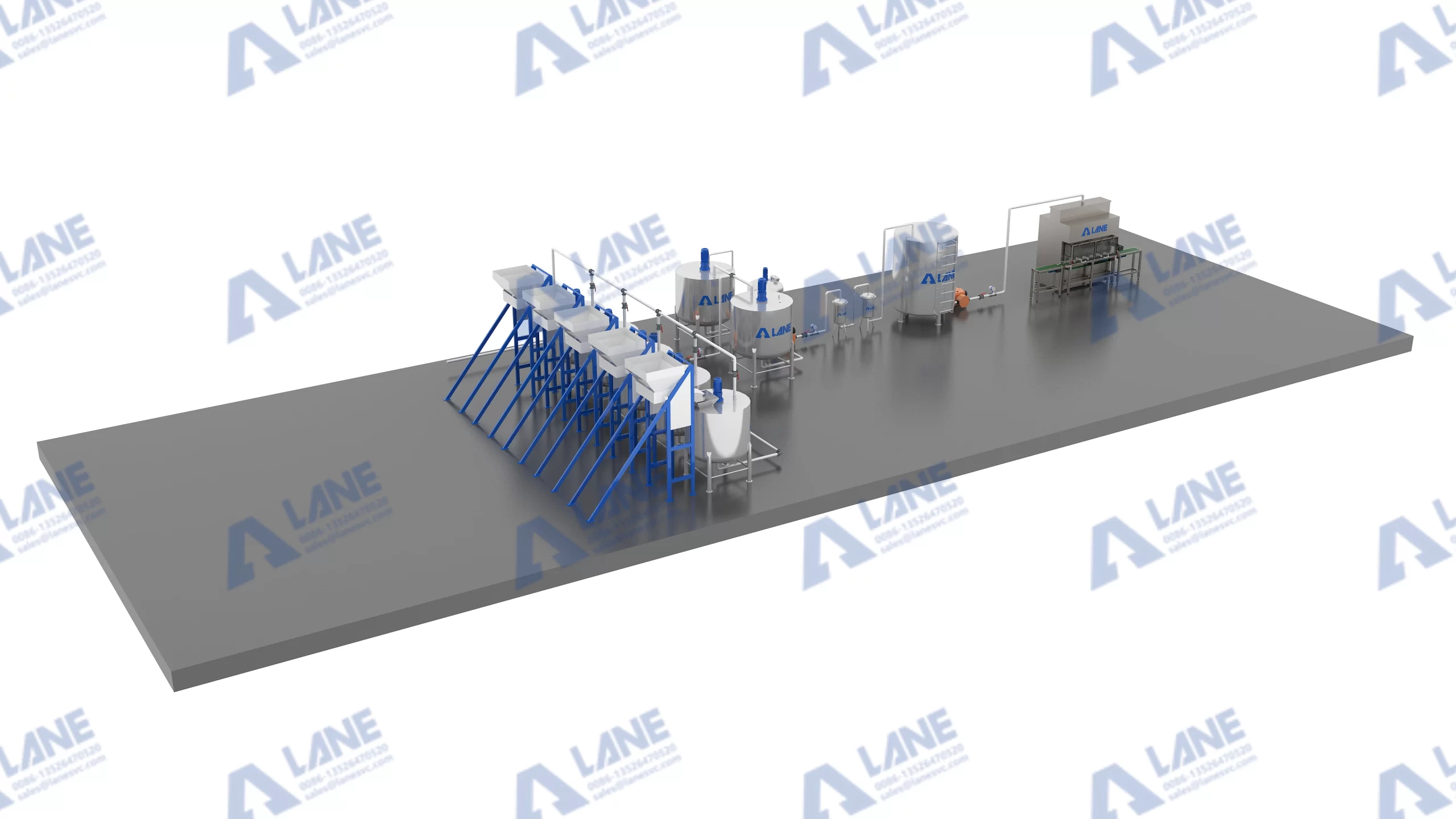

LANE has developed a state-of-the-art seaweed extract liquid fertilizer production line that integrates the latest technologies to maximize efficiency, quality, and scalability. Our machines, including cold extraction tanks and dual filtration systems, are designed for high performance, ensuring that your production line can handle large-scale operations while maintaining product consistency.

By partnering with LANE, you gain access to not only advanced technology but also the expertise needed to optimize your production process. We offer customized solutions tailored to your needs, from installation to ongoing support, ensuring that your business can thrive in the competitive organic fertilizer market.

As demand for sustainable and organic fertilizers continues to rise, the seaweed extract liquid fertilizer production line presents a promising solution. By harnessing the power of seaweed’s natural nutrients, businesses can produce high-quality, eco-friendly fertilizers that promote healthier crops and better soil health. With LANE’s innovative equipment and expertise, agricultural companies can meet the growing demand for organic inputs while reducing their environmental footprint.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Leave a Comment

LANE has more than 500 successful cases and is committed to providing customers with first-class solutions, high-end machinery and equipment, and one-stop pre-sales, sales and after-sales comprehensive customer service.