The Complete Guide to Humic Acid Liquid Fertilizer Production Lines

A humic acid liquid fertilizer production line is one of the most effective investments in producing soil-improving fertilizer, boosting crop yields while supporting sustainable agriculture. Humic acid, a naturally occurring organic compound produced by the decomposition of plants and animals, has been shown to benefit soil structure, nutrient availability, and plant health. At LANE, we design advanced humic acid liquid fertilizer production lines featuring intelligent automation systems, durable materials, and customizable configurations. Whether you operate a small facility or a large industrial plant, our systems can help you achieve efficiency, stability, and profitability.

Humic acid offers a range of agricultural benefits:

| Benefit | Agricultural Impact |

| Improves Soil Structure | Enhances aeration and water retention, creating optimal root environments. |

| Boosts Nutrient Uptake | Acts as a natural chelator, helping plants absorb NPK and micronutrients efficiently. |

| Stimulates Root Growth | Encourages deeper root systems for drought resilience. |

| Supports Microbial Life | Promotes beneficial soil microorganisms, improving long-term soil health. |

| Enhances Fertilizer Efficiency | Reduces nutrient leaching, increasing the effectiveness of applied fertilizers. |

These benefits make humic acid liquid fertilizers vital for sustainable crop production worldwide.

Producing quality humic acid liquid fertilizer starts with selecting the right raw materials:

1.Humic Acid Sources

Leonardite – High in humic acid content and easily soluble when processed.

Peat – Rich organic matter source, cost-effective in many regions.

Compost Extract – Derived from well-decomposed organic matter, offering additional nutrients.

Lignite – Low-cost option with moderate humic acid content.

2.Additives and Nutrients

To maximize fertilizer effectiveness, producers often blend humic acid with:

NPK Nutrients – Nitrogen, phosphorus, potassium for balanced plant nutrition.

Micronutrients – Zinc, boron, manganese for improved plant metabolism.

Seaweed Extracts – Enhance plant stress resistance.

Amino Acids – Support protein synthesis in plants.

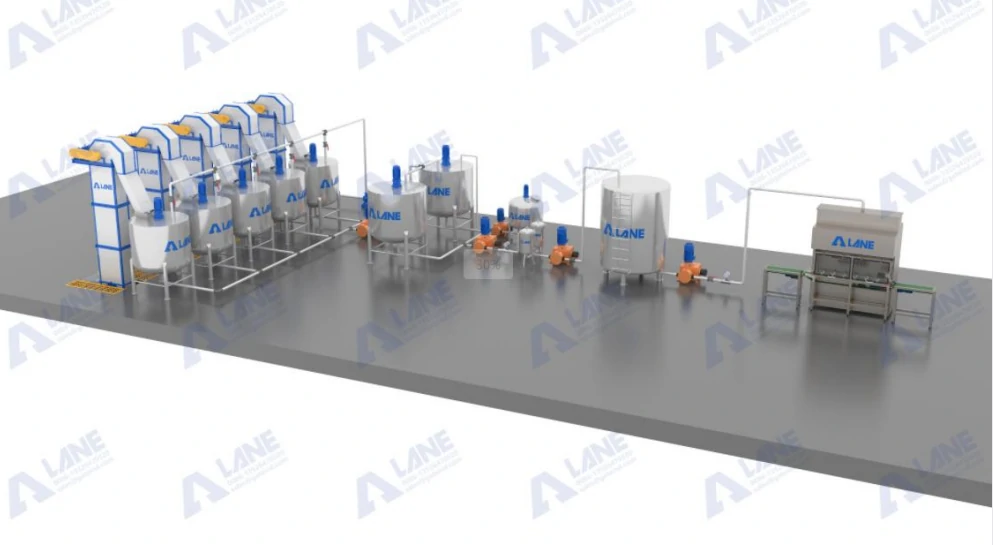

A humic acid liquid fertilizer production line is made up of a series of interconnected systems that transform raw humic acid materials into a high-quality, ready-to-use fertilizer. Each step of the process is crucial for maintaining product quality, maximizing efficiency, and ensuring compliance with agricultural standards.

Below is the complete process flow, with the typical equipment used at each stage:

(1) Raw Material Crushing & Pre-Processing

Humic acid sources like leonardite, peat, lignite, or composted organic matter often come in irregular lumps or coarse particles. Before extraction, they must be broken down into a fine, uniform size to maximize surface area for solubilization.

Equipment Used:

Humic Acid Crusher – Specially designed for brittle organic minerals, ensuring a consistent particle size below 1–3 mm.

Dust Collection System – Captures airborne dust during crushing, protecting workers and improving plant hygiene.

Uniform particle size accelerates dissolution in later stages and reduces energy consumption during mixing. LANE crushers use wear-resistant alloy blades and an optimized rotor design for high throughput and minimal downtime.

(2) Dissolving & Extraction

Once prepared, the crushed humic material is transferred to a high-temperature dissolving tank. Here, the humic matter is mixed with heated water to dissolve humic acid compounds.

Equipment Used:

High-Temperature Dissolving Tank – Equipped with thermal jackets and insulation to maintain stable heat levels.

High-Shear Agitator – Creates a vortex that disperses particles evenly and prevents settling.

Water Heating & Circulation System – Ensures consistent extraction temperature.

The solubilization process determines how much active humic acid is available in the final product. LANE uses 316L stainless steel tanks for corrosion resistance and food-grade purity, ideal for agricultural export compliance.

(3) Liquid-Liquid Separation (Optional for Premium Products)

For producers targeting export-grade fertilizers or high-end domestic markets, an additional separation stage can greatly improve purity.

Equipment Used:

Liquid-Liquid Centrifugal Extractor – Spins at high speed to separate immiscible liquid phases, removing residual organic solvents, extraction byproducts, or unwanted contaminants.

This step is especially useful if chemical extractants are used or if raw materials contain high levels of soluble impurities. LANE’s extractor systems offer continuous operation, low solvent loss, and high separation efficiency, ensuring stable production quality.

(4) Nutrient Blending

The purified humic acid extract is then enriched with essential plant nutrients. This is where the product becomes a balanced, market-ready fertilizer.

Automatic Nutrient Dosing System – Dispenses precise amounts of NPK, micronutrients, amino acids, or seaweed extract.

Automated Stainless Steel Mixing Tank – Uses variable-speed agitation for thorough blending.

Load Cell Weighing System – Ensures each batch matches the target formula.

Incorrect nutrient ratios can reduce fertilizer efficiency and harm plants. PLC-controlled blending ensures ±0.2% dosing accuracy, eliminating human error.

(5) Filtration & Purification

This step guarantees that the liquid fertilizer is clear, stable, and free from particles that could block spray equipment.

Equipment Used:

Dual Filter (Two-Stage Filtration System) – First stage removes coarse particles; second stage eliminates fine sediment.

Bag Filters / Cartridge Filters – Provide ultra-fine filtration for maximum purity.

Unfiltered fertilizer risks clogging irrigation systems and creating uneven application in the field. LANE dual filters maintain high flow rates while extending filter lifespan, reducing operational costs.

(6) pH Adjustment & Stabilization

Maintaining an optimal pH ensures nutrient stability and extends the shelf life of the fertilizer.

Equipment Used:

Inline pH Control System – Continuously measures pH and sends adjustment signals.

Chemical Dosing Pump – Adds acid or alkaline solutions in precise amounts.

pH levels outside the ideal range can cause nutrient precipitation, reducing fertilizer effectiveness.Real-time pH monitoring ensures product stability, especially important for large-volume storage.

(7) Storage

Once stabilized, the liquid fertilizer is transferred to storage tanks before packaging.

Equipment Used:

Stainless Steel Storage Tanks – Corrosion-resistant, food-grade, and hygienic.

Agitated Storage Tanks – Prevent nutrient settling during extended storage.

Proper storage prevents contamination and maintains product homogeneity. LANE’s modular tank systems can be expanded easily to meet growing demand.

(8) Bottling & Packaging

The finished fertilizer is packaged for either retail or bulk distribution.

Equipment Used:

Automatic Filling Machine – Fills bottles, jerry cans, drums, or IBC containers with ±0.5% accuracy.

Capping & Labeling Machine – Ensures airtight seals and professional labeling.

Palletizing System – Automates stacking for warehouse or shipping.

Efficient packaging ensures consistent dosing for end-users and reduces labor requirements. Flexible filling lines handle multiple container sizes with quick changeovers.

(9) Quality Control & Final Inspection

Before shipping, every batch undergoes a rigorous quality assurance protocol.

Equipment Used:

On-Site Laboratory – Tests for nutrient composition, pH, density, and microbial safety.

Batch Coding Machine – Prints traceable batch codes for compliance and recalls.

Consistency builds customer trust and ensures compliance with national and export regulations.LANE integrates QC data into the central control system, enabling traceability for every liter produced.

The uniqueness of LANE lies in its centralized PLC (Programmable Logic Controller) automation system, which connects all these processes together. Operators can monitor and adjust the entire humic acid liquid fertilizer production line through a single control panel, thereby ensuring smooth operation, minimal labor requirements, and high repeatability.

A fertilizer manufacturer in Central Java, Indonesia, faced growing demand for export-quality fertilizer from neighboring markets such as Malaysia and the Philippines. Their existing semi-manual system suffered from inconsistent nutrient ratios, high labor costs, and frequent downtime.

LANE’s Solution:

Our fully automated humic acid liquid fertilizer production line offers the following key features:

An automated nutrient metering and mixing system enables precise formulation control.

A dual filtration system ensures particle-free liquid fertilizer and secure nozzles.

A liquid-liquid centrifugal extractor enhances purity to meet export standards.

Results after 12 months:

Production capacity increased by 35% without the need for additional labor. Product consistency improved to 99% batch accuracy, enabling the company to pass all export quality tests. Ultimately, operating costs were reduced by 25% thanks to automation and reduced maintenance downtime.

Driven by factors such as the trend towards sustainable agriculture, soil degradation challenges, and stricter environmental regulations, global demand for humic acid liquid fertilizers is expected to grow significantly over the next decade. As farmers seek solutions that can both increase yields and protect soil health over the long term, humic acid has become a scientifically proven and economically viable option.

Global Growth Drivers

Soil Health Crisis – Continuous monoculture, excessive use of chemical fertilizers, and soil erosion have led to the depletion of soil organic matter. Humic acid fertilizers can restore microbial activity, improve soil structure, and increase nutrient retention.

Government Incentives – Many countries, including China, India, and EU member states, are providing subsidies or policy support for organic fertilizers and humic acid fertilizers.

Organic and ecological agriculture are booming – Consumer demand for chemical-free products is driving growers to adopt more sustainable fertilization methods.

Export Potential – High-quality humic acid liquid fertilizers are becoming increasingly popular in markets such as Southeast Asia, Africa, and Latin America.

Regional Highlights

Asia Pacific – Thanks to high agricultural yields and the growing popularity of sustainable agriculture, the Asia Pacific region has become the fastest-growing market.

The Middle East and Africa – due to arid climates and low organic matter content – are experiencing strong demand for soil conditioners.

Europe – driven by strict environmental regulations and a robust organic farming industry.

For fertilizer manufacturers, investing in a humic acid liquid fertilizer production line is not only about meeting current demand but also about capitalizing on the next wave of agricultural innovation. LANE’s automated production lines enable producers to quickly scale up, maintain product consistency, and tap into lucrative export markets.

A humic acid liquid fertilizer production line represents a powerful opportunity for both established fertilizer manufacturers and new entrants to the market. By combining natural soil enhancement properties with cutting-edge automation technology, producers can deliver products that farmers trust and depend on season after season.LANE has proven experience in delivering turnkey solutions — from plant design and equipment supply to training and after-sales service. Our systems are engineered to maximize production efficiency, reduce operating costs, and maintain consistent product quality for domestic and international markets.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Leave a Comment

LANE has more than 500 successful cases and is committed to providing customers with first-class solutions, high-end machinery and equipment, and one-stop pre-sales, sales and after-sales comprehensive customer service.