How Solid Powder Water Soluble Fertilizer Production Line Equipment Machines Build Efficient Plants

When planning a medium-scale fertilizer plant, the first consideration is often how to select stable and cost-effective solid powder water soluble fertilizer production line equipment machines that can meet production targets while allowing room for future growth. With water soluble fertilizers becoming increasingly important in modern, precision agriculture, manufacturers now focus more on accuracy, consistency, and reliability than on automation alone.

An annual capacity of 10,000–20,000 tons is widely recognized as a balanced investment scale. It is large enough to support commercial distribution, yet compact enough to manage efficiently. At this level, choosing the right machines is the key to long-term operational success.

The popularity of water soluble fertilizer continues to grow due to its fast dissolution, high nutrient absorption, and suitability for fertigation systems. Solid powder products require strict control over mixing uniformity and ingredient accuracy.

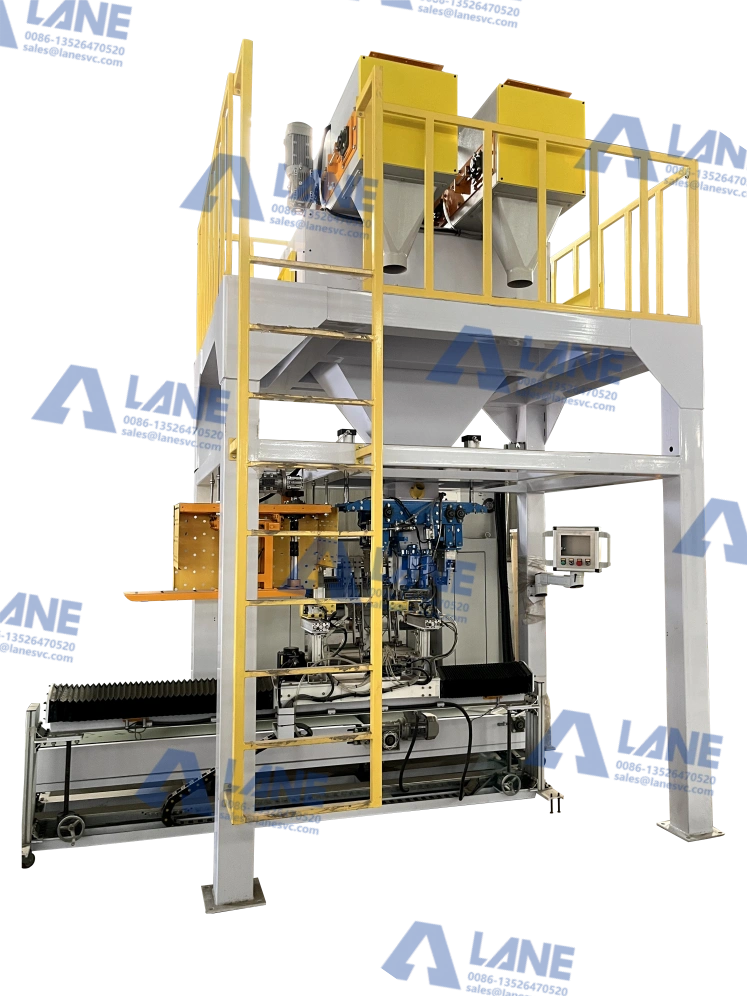

A production system based on solid powder water soluble fertilizer production line equipment machines is designed specifically to meet these requirements. Compared with traditional fertilizer machinery, these machines handle fine powders more precisely, ensuring consistent product quality and excellent water solubility.

For this production capacity, the entire line is organized by machine function rather than abstract process steps. The recommended configuration includes:

Together, these solid powder water soluble fertilizer production line equipment machines form a stable, efficient, and flexible manufacturing solution.

Production begins with the manual feeding hopper. Operators add raw materials such as urea, potassium nitrate, ammonium sulfate, and trace elements into designated hoppers.

In modern solid powder water soluble fertilizer production line equipment machines, feeding hoppers are equipped with dust collectors to keep the working environment clean and improve operator safety. Manual feeding is ideal at this scale because it allows fast formula changes and reduces equipment complexity.

Materials from the feeding hoppers enter the automatic electronic batching scale system. This machine weighs each ingredient according to the preset formula using high-precision load cells and PLC control.

Among all solid powder water soluble fertilizer production line equipment machines, batching systems play a decisive role in product quality. Accurate weighing ensures stable nutrient ratios, which directly affect fertilizer performance and customer satisfaction.

After batching, materials are transferred to the mixing tanks. These stainless-steel mixing tanks are commonly used for solid powder water soluble fertilizers due to their strong mixing performance and short mixing time.

A high-quality mixing tank is one of the core solid powder water soluble fertilizer production line equipment machines. It guarantees uniform blending of different materials, prevents segregation, and ensures that every bag of fertilizer has consistent nutrient content.

Once mixing is complete, the finished powder is conveyed to a quantitative packing machine. This machine fills fertilizer into bags with preset weights, such as 10 kg, 20 kg, or 25 kg.

In practical production, solid powder water soluble fertilizer production line equipment machines with the packing systems provide an excellent balance between speed and control. Operators can visually inspect bags while the machine ensures accurate filling.

Filled bags are then sealed using either heat sealing machines or sewing machines, depending on the packaging material.

These sealing units are essential supporting components of solid powder water soluble fertilizer production line equipment machines. Their simple structure ensures reliable operation, easy maintenance, and compatibility with different types of fertilizer bags.

The final step of the line is palletizing. Robotic palletizing machines automatically stack finished bags onto pallets according to predefined patterns.

As an advanced part of solid powder water soluble fertilizer production line equipment machines, robotic palletizers improve efficiency, reduce labor costs, and enhance workplace safety. They also create neat, standardized pallets that are convenient for transportation and storage.

This configuration is widely adopted because it reflects real production needs. Fully automated systems may look impressive but can be expensive and inflexible, especially for plants producing multiple fertilizer formulas.

By selecting well-matched solid powder water soluble fertilizer production line equipment machines, manufacturers can maintain high product quality while keeping operations practical and adaptable. Each machine performs a clear role and can be upgraded independently as demand grows.

At LANE, we have been specializing in fertilizer machinery manufacturing in China for more than 20 years. Our experience allows us to understand how each piece of equipment performs in real factory conditions.

We design, manufacture, and install complete production lines centered on reliable solid powder water soluble fertilizer production line equipment machines, tailored to your raw materials, plant layout, and capacity requirements. Our professional engineering team supports every stage, from initial design to on-site installation and commissioning.

We are proud to offer comprehensive after-sales service. Whether it is maintenance, troubleshooting, or equipment upgrades, we are always ready to ensure your production line operates smoothly. LANE equipment complies with ISO 9001 and CE international quality standards, giving customers confidence in long-term reliability.

In addition to water soluble fertilizer systems, we also supply NPK production lines, compound fertilizer equipment, and organic fertilizer machines, allowing us to provide integrated solutions when needed.

A fertilizer plant with an output of 10,000–20,000 tons per year is often the foundation for long-term development. With a rational layout and the right solid powder water soluble fertilizer production line equipment machines, manufacturers can expand capacity, increase automation, or diversify products without rebuilding the entire plant.

This machine-focused design ensures that today’s investment remains valuable as market demand evolves. In a competitive fertilizer industry, flexibility, reliability, and consistent quality are what truly define a successful production line.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Leave a Comment

LANE has more than 500 successful cases and is committed to providing customers with first-class solutions, high-end machinery and equipment, and one-stop pre-sales, sales and after-sales comprehensive customer service.