Small Scale Liquid Fertilizer Production Line: Sustainable Solutions for Local Agriculture

The global agricultural industry is shifting toward precision farming and sustainable resource use. Farmers today face rising input costs, unpredictable weather, and the urgent need to produce more food on limited land. Liquid fertilizers are gaining popularity as they deliver nutrients directly to crops with high efficiency. However, industrial-scale production lines are often too costly and oversized for smallholder farmers and regional cooperatives.

This is where the small scale liquid fertilizer production line proves its value. Compact, flexible, and affordable, such a system allows communities, farmer groups, or small businesses to produce high-quality liquid fertilizers locally. Whether using synthetic raw materials like urea or organic resources such as fish waste, seaweed, or crop residues, these production lines convert raw inputs into nutrient-rich solutions that are easy to apply via irrigation, spraying, or fertigation.

The need for flexible, efficient, and sustainable fertilizer solutions has never been greater. For many regions, especially where agriculture is dominated by smallholder farmers, investing in a large industrial plant is not practical. A small scale liquid fertilizer production line offers a middle ground — advanced technology in a compact, affordable format.

First, it reduces reliance on imported fertilizers. Small farmers often face rising prices and supply chain disruptions. By producing fertilizers locally, cooperatives and small businesses can guarantee a steady supply at stable costs.

Second, it offers flexibility in formulation. Large-scale industrial production typically focuses on standardized products, but small-scale systems allow adjustments based on soil tests, crop requirements, and climate conditions. For example, a region focused on fruit crops may produce potassium-rich blends, while cereal-growing regions can prioritize nitrogen.

Third, it creates opportunities for community-level development. By owning and managing a small scale liquid fertilizer production line, cooperatives create jobs, build technical capacity, and retain more value within local economies.

Finally, it aligns with sustainable agriculture goals. Recycling organic resources like manure, crop residues, or algae into fertilizer reduces waste, closes nutrient loops, and minimizes environmental impact. For countries aiming to improve soil health and reduce pollution, these plants are a key tool.

Although smaller in scale, the process closely mirrors industrial systems, ensuring product quality and consistency. Each step plays a crucial role in producing stable, nutrient-rich fertilizers.

Step 1: Raw Material Preparation

Inputs: Urea, potassium nitrate, phosphoric acid, and trace element salts for chemical formulations; or organic inputs like fish protein hydrolysates, algae extracts, or crop residues for organic blends.

Goal: Select and weigh the right proportions to achieve the target nutrient balance (e.g., NPK ratios).

Step 2: Mixing

Equipment: Stainless steel mixing tank equipped with agitators and sometimes heating coils.

Process: Raw materials are dissolved and homogenized. Heating helps dissolve difficult salts, while continuous mixing ensures uniform concentration.

Importance: Homogeneity guarantees that every liter of fertilizer has the same nutrient profile.

Step 3: Filtration

Equipment: Dual filter system.

Function: Removes impurities and undissolved solids.

Impact: Prevents clogging of drip irrigation systems and sprayers, ensuring reliable field application.

Step 4: Stabilization and Additives

Chelating agents (EDTA, DTPA) are added to keep micronutrients like Fe, Zn, and Mn soluble.

pH adjustment ensures long-term stability.

Optional additives include growth stimulants such as humic acids or amino acids.

Step 5: Storage and Testing

Fertilizer is transferred to storage tanks, often made of stainless steel or food-grade plastic.

Samples are tested for nutrient content, solubility, and shelf life.

Step 6: Packaging

Equipment: Automatic packaging machine suitable for bottles, jerrycans, or drums.

Output: Fertilizers are sealed in containers of different sizes, labeled with nutrient analysis, instructions, and batch numbers for traceability.

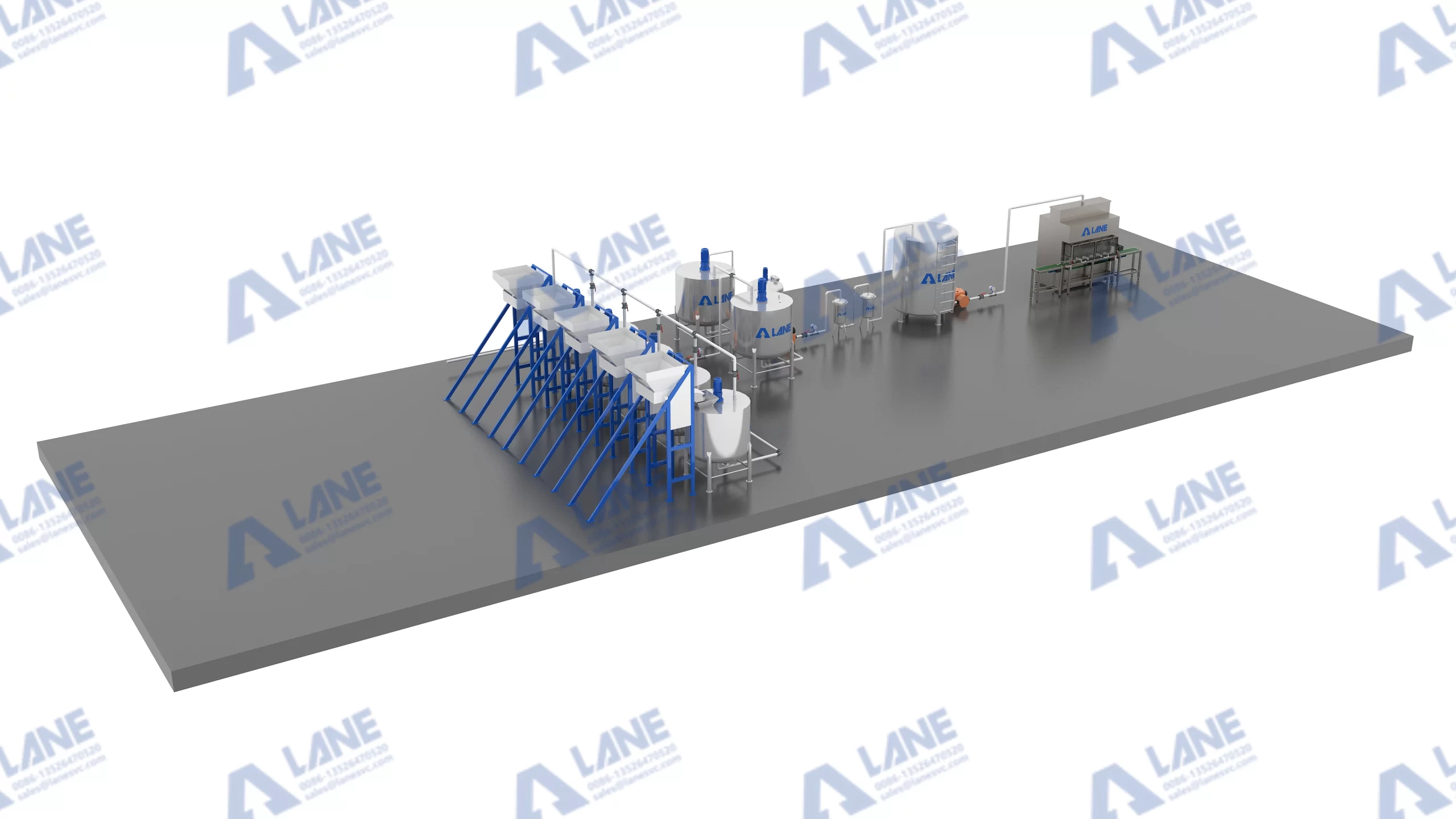

A well-designed small scale liquid fertilizer production line typically includes:

Stainless Steel Mixing Tank – Capacities from 500L to 2000L, designed for durability and hygiene.

Dual Filter System – Guarantees purity and prevents blockages in irrigation equipment.

Storage Tanks – Intermediate holding before packaging, available in modular sizes.

Automatic Packaging Machine – Adjustable for various container sizes.

Auxiliary Equipment – Pumps, pipelines, pH sensors, and dosing systems for accuracy.

These machines are compact, easy to operate, and require minimal maintenance, making them ideal for cooperatives or small agribusinesses.

The versatility of a small scale liquid fertilizer production line makes it applicable across multiple farming systems.

Greenhouse Production: Greenhouse vegetables such as tomatoes, cucumbers, and peppers benefit greatly from fertigation with liquid fertilizers. Controlled environments allow precise adjustment of nutrient concentration, leading to consistent yields and premium-quality produce.

Orchards and Vineyards: Orchards producing apples, citrus, or grapes need fertilizers that support flowering and fruit development. Liquid fertilizers can be customized with micronutrients like zinc and boron, which are essential for reproductive growth. Drip irrigation systems ensure nutrients are delivered right to the roots.

Cereal and Grain Farming: Large-scale staple crops like maize, wheat, and rice often suffer from nitrogen losses when urea is applied in granular form. Using liquid nitrogen fertilizers reduces volatilization and ensures more nutrients are absorbed by the plants.

Organic Farming Systems: Farmers focusing on certified organic crops can use production lines to process animal manure, compost extracts, or fish hydrolysates into liquid fertilizers. These inputs support soil biodiversity while meeting organic certification standards.

| Advantage | Impact on Farmers and Communities |

| Cost-Effective | Affordable production, reducing reliance on expensive imports. |

| Customizable | Formulations adapted to crop growth stages or regional soil needs. |

| Sustainable | Encourages recycling of organic waste, reducing environmental impact. |

| Efficient | Fertilizers are absorbed faster by crops, leading to higher yields. |

| Localized Production | Strengthens regional food security and reduces transport costs. |

A cooperative in central Kenya faced high costs for imported fertilizers and limited access during peak growing seasons. By installing a small scale liquid fertilizer production line, they began processing cow manure and crop residues into organic liquid fertilizer.

The line included a 1000L stainless steel mixing tank, a dual filter system, and semi-automatic packaging machines. Farmers used the fertilizers on maize and beans, reporting a 15–20% increase in yields while spending less on inputs. Additionally, soil health indicators such as organic matter content improved within two years. The project not only lowered costs but also created local jobs for youth in the community who were trained to operate the system.

In southern Turkey, greenhouse tomato growers faced intense competition in export markets. They needed a reliable way to improve fruit size, sweetness, and shelf life. By adopting a small scale liquid fertilizer production line, they produced potassium-rich blends tailored to the crop’s fruiting stage.

The liquid fertilizer was integrated into drip irrigation systems, reducing water and fertilizer waste by 25%. The farmers reported improved tomato firmness and an extended shelf life of up to one week, which made their produce more competitive in European markets. Over time, the cooperative was able to scale production, offering surplus fertilizer to neighboring farms as an additional revenue source.

The future of the small scale liquid fertilizer production line is promising, driven by both global trends and local needs.

Integration with Precision Agriculture: As digital agriculture tools become more widespread, even small-scale systems can integrate with sensors and monitoring devices. This allows farmers to adjust formulations based on soil moisture, nutrient levels, and crop growth stages in real time.

Sustainable and Circular Agriculture: Future systems will increasingly use waste streams — fish processing residues, algae, or municipal organics — as inputs. This not only creates value from waste but also reduces environmental pollution, aligning with the goals of circular economies.

Affordable Renewable Energy Solutions: Energy costs can be significant in fertilizer production. By integrating solar-powered pumps and mixers, small-scale systems can reduce operating expenses and become even more sustainable, especially in sunny regions.

Expanding Market Opportunities: As awareness of liquid fertilizers grows, more cooperatives and farmer groups will invest in production lines. Regional markets are likely to see an increase in localized fertilizer production, strengthening food security and reducing dependence on global supply chains.

The small scale liquid fertilizer production line offers a practical and sustainable way to empower smallholder farmers, cooperatives, and local agribusinesses. With its affordable investment, flexible production, and environmental advantages, it bridges the gap between traditional farming and modern precision agriculture.

From maize fields in Kenya to tomato greenhouses in Turkey, success stories show how localized liquid fertilizer production can transform farming outcomes. Looking ahead, these compact systems will not only improve yields but also strengthen local food systems, reduce environmental footprints, and open new opportunities for rural communities worldwide. As demand for eco-friendly solutions rises, the small scale liquid fertilizer production line will remain a vital tool in shaping the future of resilient, sustainable agriculture.

In addition, small-scale systems encourage innovation at the grassroots level. Farmers and cooperatives can experiment with new formulations, integrate digital monitoring, or link production with organic certification programs. This adaptability ensures that the small scale liquid fertilizer production line is not just a tool for today but an evolving solution for tomorrow’s agricultural challenges.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Leave a Comment

LANE has more than 500 successful cases and is committed to providing customers with first-class solutions, high-end machinery and equipment, and one-stop pre-sales, sales and after-sales comprehensive customer service.