From Sea to Soil: Building a Production Line for Combined Seaweed and fish emulsion liquid fertilizer

The agriculture industry is moving towards sustainability. Organic and eco-friendly fertilizers are now the focus of market attention. By organic fertilizer, most of the time we understand organic granular fertilizers, but recently organic liquid fertilizers are getting attention because of their versatility. Seaweed and fish emulsion liquid fertilizers have been revered for decades. There are very few organic inputs that can compete with these two materials in terms of nutrients.

Seaweed and fish emulsion liquid fertilizer is a product derived from marine resources. Seaweed extract is packed with natural growth hormones, micronutrients, and complex carbohydrates, while fish emulsion has nitrogen, phosphorus, and amino acids. Both of these are very popular as single main raw materials for liquid fertilizer. Seaweed and fish emulsion liquid fertilizer combines both of these heavyweight raw materials into one unique liquid fertilizer.

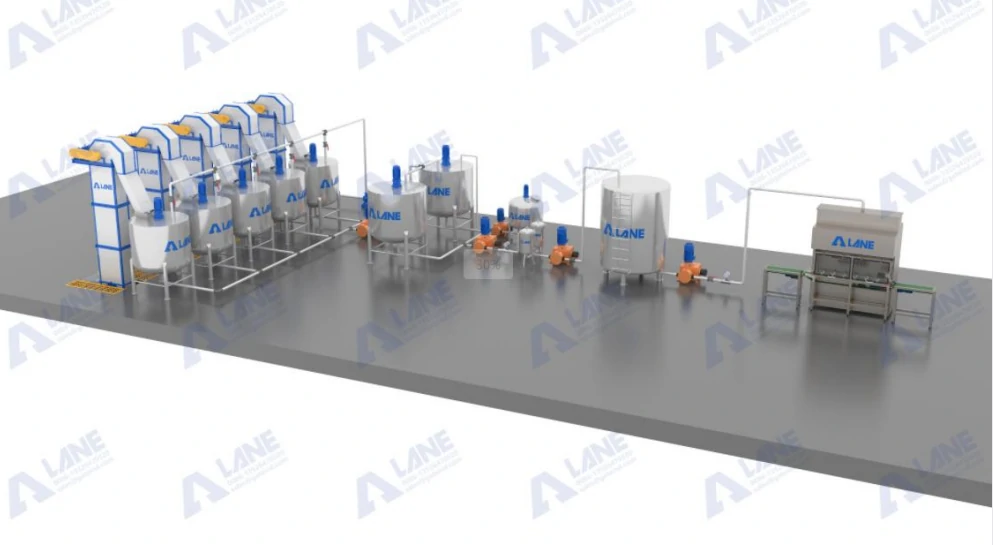

The production of high-quality seaweed and fish emulsion liquid fertilizer requires specialized equipment for its production processes. LANE Heavy Industry, a leading manufacturer of agricultural and heavy machinery, has developed a reliable, efficient, and scalable production line that can handle the production of seaweed and fish emulsion liquid fertilizer.

The creation of a premium combined fertilizer is a meticulous, multi-stage process that harmonizes biological science and precision engineering.

Stage 1: Raw Material Reception & Preparation

You have to source fresh fish by-products and seaweed (typically Ascophyllum nodosum or Kelp). Fish by-products are minced while seaweed is washed to remove salts and sand.

Stage 2: Controlled Hydrolysis & Digestion

This is where the prepared fish and seaweed are introduced into LANE’s specialized, temperature-controlled Digestion Reactors. Here, with the help of enzymes, controlled enzymatic hydrolysis breaks down proteins, carbohydrates, and fats. This is a low-temperature method which preserves the growth hormones in the seaweed and the amino acids in the fish. In high-heat chemical processes, these are often destroyed.

Stage 3: Liquefaction & Separation

The digested slurry is transferred to High-Shear Mixing tanks. This mixing process reduces particle sizes and creates a homogeneous mixture. Then the material passes through a series of High-Speed Centrifugal Filters or solid-liquid separators to separate the clear, nutrient-rich liquid from insoluble bones and fibrous material. LANE Heavy Industry combines both of these filters to create a smooth, stable emulsion.

Stage 4: Formulation & Enrichment

The clear, smooth fish and seaweed hydrolysate is now the base fertilizer. It is then sent to LANE’s Formulation Tanks to be blended with additional minerals like potassium or calcium or beneficial microbes to create a premium custom mix. LANE’s machinery is equipped with pH meters that can help you ensure stability.

Stage 5: Pasteurization & Stabilization

To eliminate potential pathogens and increase product shelf-life without damaging the base fertilizer, the liquid passes through a UV sterilizer. Alternatively, we can also use a Low-Temperature Pasteurization Unit. This step is carefully calibrated to be effective yet gentle.

Stage 6: Automated Filling & Packaging

The finished seaweed and fish emulsion liquid fertilizer is then conveyed to a storage tank where the fertilizer is temporarily held before being sent to an automated filling line, which accurately bottles, labels, and packs the product for distribution.

LANE’s production line is built with food-grade and corrosion-resistant machinery. It is designed for the demanding environment of organic fertilizer production.

Seaweed and fish emulsion liquid fertilizer is not just a product which is created by mixing two products. It requires proper care, technique, and control to create a liquid fertilizer. The LANE production line implements co-processing. Our line digests the fish and seaweed together to create stable compounds where the molecules of both raw materials begin to interact during hydrolysis. The finished liquid fertilizer is a premium fertilizer with complex and stable compounds. Integrated lines also offer reduced energy consumption, lower carbon footprint, and a streamlined workflow that minimizes handling and cross-contamination.

There are many benefits of seaweed and fish emulsion liquid fertilizer created with a LANE-engineered production line:

Q1: What is the main advantage of a combined seaweed and fish emulsion over single-input fertilizers?

A: The combination provides a full-spectrum solution. Fish offers fast-acting NPK and amino acids, while seaweed contributes long-acting hormones, vitamins, and micronutrients. Together, they promote immediate growth and long-term plant health and resilience.

Q2: Is the LANE production line suitable for small-scale operations?

A: Yes. LANE Heavy Industry offers modular and scalable solutions. We can design compact, semi-automated lines for regional producers as well as large, fully automated facilities for high-volume output.

Q3: How does the enzymatic hydrolysis process differ from traditional chemical or heat processing?

A: Enzymatic hydrolysis uses natural enzymes at controlled temperatures (typically 40-60°C). This “gentle” method preserves the bioactive compounds in both seaweed and fish that are vital for the fertilizer’s efficacy, unlike harsh chemical or high-heat methods which can degrade them.

Q4: What raw material quality is required for this line?

A: The line can process various qualities, but for a premium product, fresh or properly preserved fish by-products (frames, offal) and clean, sustainably harvested seaweed are recommended. LANE can advise on optimal raw material specifications.

Q5: What kind of after-sales support does LANE provide?

A: LANE provides comprehensive support including installation supervision, operator training, detailed process manuals, and a readily available supply of wear parts and technical support.

The development of green agriculture has brought broad market prospects for seaweed and fish emulsion liquid fertilizer. Building a production line for seaweed and fish emulsion liquid fertilizer is an investment which not only generates profit but also helps sustain the green economy. It meets the global demand for high-performance, sustainable organic inputs. With LANE Heavy Industry’s production line solution for seaweed and fish emulsion liquid fertilizer, producers gain more than just machinery; they gain a turnkey solution for manufacturing a product that nourishes crops, revitalizes soil, and supports planetary health.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Leave a Comment

LANE has more than 500 successful cases and is committed to providing customers with first-class solutions, high-end machinery and equipment, and one-stop pre-sales, sales and after-sales comprehensive customer service.