A Closer Look at the Protein-Based Liquid Fertilizer Production Line

In recent years, sustainable agriculture has moved from a buzzword to a real demand. Farmers, distributors, and investors are all paying attention to the protein-based liquid fertilizer production line because it fits modern farming needs so well. It turns natural protein sources into easy-to-use liquid fertilizer, helping crops grow while protecting the soil and the environment.

This type of production line is not just about machines. It is about smart use of resources, stable output, and reliable quality. As more regions push for greener agriculture, the protein-based liquid fertilizer production line is becoming a common topic in industry news and farming communities.

Protein-based liquid fertilizer is made from materials rich in protein. Through controlled processing, these proteins are broken down into amino acids and small nutrients that plants can absorb quickly. The result is a liquid product that is gentle, efficient, and suitable for many crops.

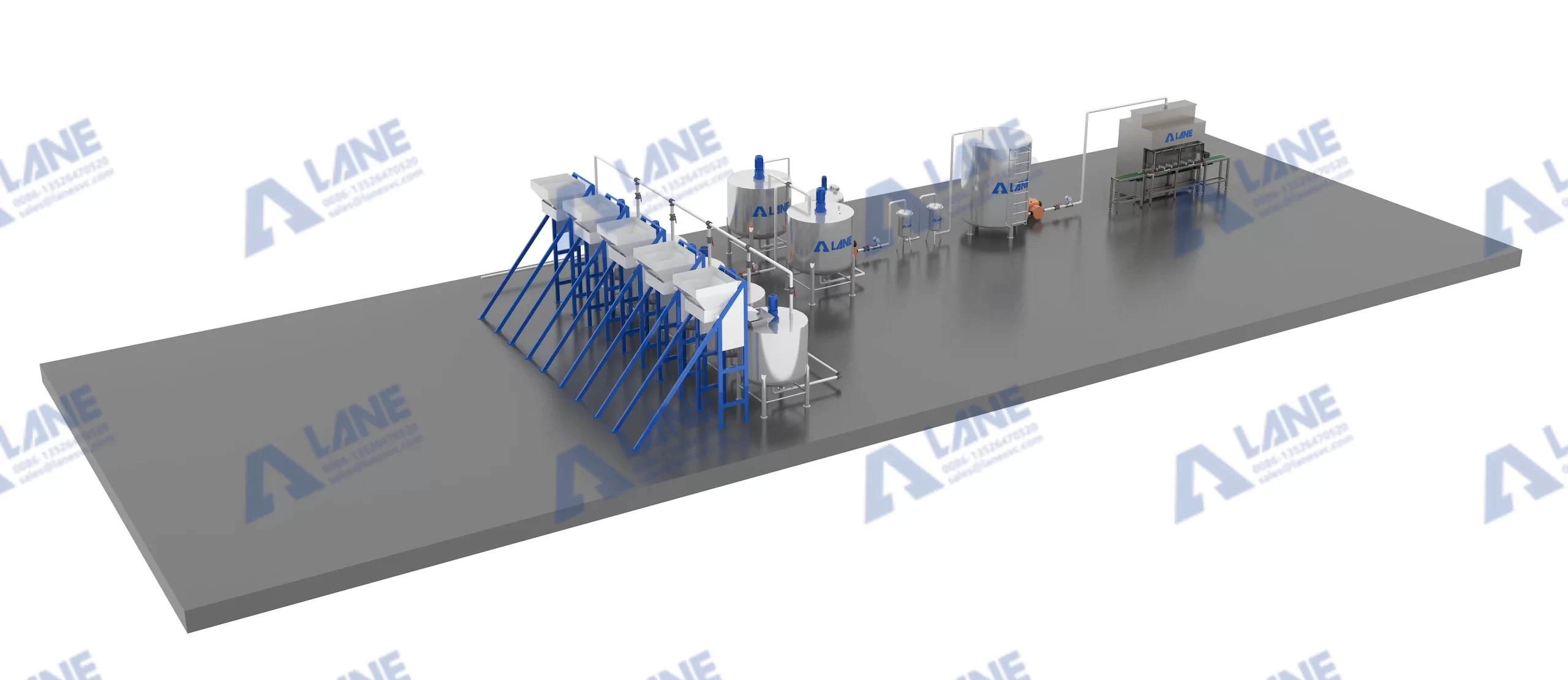

Behind this product stands the protein-based liquid fertilizer production line, which connects raw material handling, mixing, fermentation or enzymatic treatment, filtration, and filling into one smooth process. The goal is simple: stable quality and easy operation.

One of the biggest advantages of this fertilizer is the wide range of raw materials it can use. This makes the protein-based liquid fertilizer production line flexible and cost-effective.

Common raw materials include:

These materials are often locally available and sometimes considered waste. Turning them into fertilizer adds value and reduces environmental pressure. With proper processing, unpleasant odors and impurities are controlled, making the final product safe and farmer-friendly.

Liquid fertilizer has clear advantages compared to traditional solid products. In a well-designed protein-based liquid fertilizer production line, nutrients are evenly mixed and stabilized in liquid form.

Key benefits include:

For farmers, this means less waste and better results with less effort.

The popularity of the protein-based liquid fertilizer production line is closely linked to the product’s real benefits in the field.

Some of the most valued advantages are:

These advantages make protein-based liquid fertilizer especially attractive in modern, high-value farming.

From an environmental point of view, the protein-based liquid fertilizer production line supports recycling and low-emission production. Using organic by-products reduces waste and lowers dependence on chemical inputs.

Economically, production lines can be scaled. Small plants can serve local markets, while larger lines support export and industrial supply. This flexibility lowers entry barriers and allows businesses to grow step by step.

Across many regions, demand for organic and bio-based fertilizers is rising. Governments encourage reduced chemical use, and consumers care more about how food is grown. In this context, the protein-based liquid fertilizer production line is seen as a long-term investment rather than a short-term trend.

Producers who enter this field early often gain strong brand recognition and stable customer bases.

At LANE, we have been working in fertilizer machinery manufacturing for over 20 years. We understand the real challenges customers face when setting up a protein-based liquid fertilizer production line, from layout planning to daily operation.

Our professional engineering team works closely with clients to design and manufacture equipment that fits their raw materials, capacity needs, and local conditions. We believe no two projects should be exactly the same.

We do not just sell machines. We provide complete solutions. For every protein-based liquid fertilizer production line, we offer customized design, equipment manufacturing, on-site installation, and operator training.

Our product range covers organic fertilizer, compound fertilizer, and liquid fertilizer machinery. All equipment is built to meet ISO9001 and CE standards, ensuring stable performance and long service life.

A production line only creates value when it runs smoothly. That is why we stay involved long after delivery. For each protein-based liquid fertilizer production line, we provintenance guidance, trode maiubleshooting support, and upgrade services when needed.

Our goal is simple: help customers keep their lines running efficiently and profitably.

The protein-based liquid fertilizer production line combines sustainable raw materials, practical advantages, and strong market potential. With the right equipment and a reliable partner, it can become a solid foundation for modern fertilizer production.

At LANE, we are proud to support this growing industry with professional design, customized solutions, and dependable service—helping our customers turn natural protein resources into real agricultural value.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Leave a Comment

LANE has more than 500 successful cases and is committed to providing customers with first-class solutions, high-end machinery and equipment, and one-stop pre-sales, sales and after-sales comprehensive customer service.