How Modern Factories Produce Liquid Nitrogen Fertilizer

To understand how today’s fertilizer factories produce liquid nitrogen fertilizer , you first need to picture a lively industrial landscape where chemistry, engineering, and smart machinery work hand in hand. Within the first steps of the process, raw materials are transformed, blended, cooled, and stabilized to produce liquid nitrogen fertilizer at scale—without ever feeling overly complicated to the average observer.

Although the topic sounds technical, the journey becomes surprisingly fascinating once you look at the equipment involved, how its features support each processing stage, and how an experienced manufacturer ensures that everything comes together smoothly. In this article, we’ll explore how factories produce liquid nitrogen fertilizer from start to finish, focusing on the machinery that powers this transformation. And we’ll do it in a light, news-friendly tone that feels like a visit to a well-run plant rather than a chemistry lecture.

Along the way, we’ll share how our own company supports clients seeking to produce liquid nitrogen fertilizer through full-service engineering, equipment manufacturing, and turnkey production-line solutions.

Before jumping into the equipment, it helps to understand why so many facilities are being upgraded specifically to produce liquid nitrogen fertilizer . Liquid forms offer excellent nutrient availability, consistency, and compatibility with modern irrigation systems. They blend easily with other nutrients and can be applied with precision, minimizing waste and helping farmers respond quickly to crop needs.

This rising demand also means producers are looking for manufacturing lines that are safer, more energy-efficient, and easier to maintain—all factors that influence equipment design.

The Core Production Concept

While different manufacturers adopt their own variations, the main idea remains the same: controlled mixing, reaction, and stabilization steps combine urea, ammonium nitrate, and other nitrogen sources into a uniform liquid solution. The goal is to produce liquid nitrogen fertilizer that remains stable in storage, easy to transport, and reliable during application.

Factories don’t follow home-scale recipes—these are tightly managed industrial systems. That’s why the machinery matters so much. Each piece is designed to protect operators, guarantee quality, and maintain continuous output.

Let’s walk through the major equipment typically used to produce liquid nitrogen fertilizer, focusing on their features and real-world value.

Long before any reaction takes place, materials must be stored safely and delivered at controlled rates. Tanks, silos, and sealed vessels are common. Good feeding systems prevent contamination, reduce manual handling, and ensure stable input—essential when you want to produce liquid nitrogen fertilizer that meets consistent standards.

Key Features:

Mixing is where the magic begins. Industrial liquid-phase mixers ensure raw components combine evenly. Agitation systems, internal baffles, and temperature-regulating jackets help maintain stable conditions.

These blending tanks are designed for high-volume operation while providing the precision necessary to produce liquid nitrogen fertilizer with uniform nutrient content.

Functional Highlights:

Heating and Dissolving Units

Some nitrogen ingredients dissolve or react more efficiently at specific temperatures. Heating systems—often steam or thermal-oil based—help ensure proper dissolution without overshooting safety limits. These units work seamlessly with mixing tanks to support factories aiming to produce liquid nitrogen fertilizer in high volumes.

Advantages:

Once the solution reaches the desired concentration, it often passes through filters to remove impurities. The dual-filters keep the product stable and reduce downstream issues.

Impurity control is particularly important when the goal is to produce liquid nitrogen fertilizer suitable for long-term storage and uniform field application.

Even when reactions are controlled, fertilizer solutions often exit the mixing stage warmer than ideal. Cooling systems—usually heat exchangers—drop the temperature to a safe and stable level before storage.

Well-designed cooling improves product stability and prevents premature degradation.

Finished liquid nitrogen fertilizer is stored in large, insulated tanks engineered to maintain quality. These storage tanks must withstand chemical exposure and resist corrosion while keeping temperature levels predictable.

When the objective is to produce liquid nitrogen fertilizer at commercial scale, long-term storage reliability becomes a critical component of the entire operation.

Depending on the operation, the final product may be loaded into tanker trucks, sealed into IBC containers, or prepared for bulk distribution. Automation ensures accuracy and prevents spills.

High-precision packaging machines support safe final-stage handling while maintaining consistent product volume.

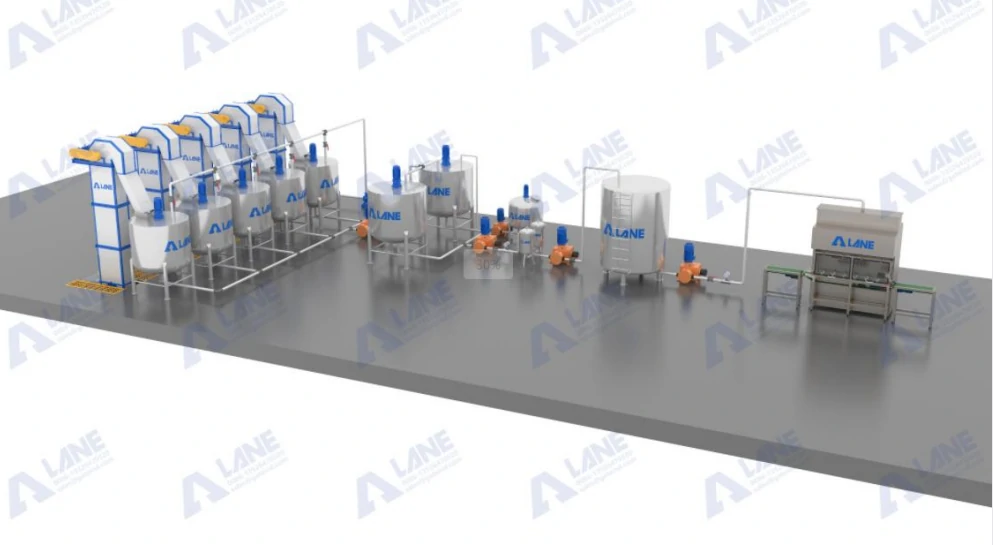

For factories exploring or expanding their ability to produce liquid nitrogen fertilizer, reliable equipment and engineering support are essential. This is where our company , LANE , steps in.

With more than two decades of experience dedicated to fertilizer machinery manufacturing, we’ve developed a deep understanding of full-scale production line design. Our engineering team works directly with clients to create complete systems—from layout to installation—tailored to the type of nitrogen fertilizer they want to produce.

We also stay with our customers long after installation. Whether it’s maintenance, technical upgrades, troubleshooting, or optimizing output efficiency, our team provides continuous support to keep production lines running at their best. Our equipment follows internationally recognized ISO 9001 and CE quality standards, ensuring long-term reliability.

Beyond liquid nitrogen fertilizers, we supply full fertilizer production lines, including NPK systems, organic fertilizer machinery, and compound fertilizer equipment. This broad scope allows us to deliver end-to-end solutions for producers looking to modernize or expand.

Though the machines are impressive, the real story lies in the people running them. Operators rely on stable systems that reduce guesswork, minimize hazards, and streamline daily work. Modern designs help simplify tasks, automate repetitive processes, and cut down on manual intervention.

The result isn’t just improved output—it’s a safer, more efficient, more confident working environment. When a factory chooses to produce liquid nitrogen fertilizer, it’s building a long-term system that brings together chemistry, agriculture, engineering, and logistics into one smooth operation.

As sustainable agriculture becomes a global priority, the market for liquid nitrogen fertilizers continues to evolve. Producers seek cleaner processes, smarter automation, and equipment that uses less energy while delivering higher output.

This innovation benefits farmers and the planet alike. And as technology moves forward, we remain committed to helping clients navigate the newest systems, expand their capabilities, and operate production lines as safely and efficiently as possible.

Whether starting a new facility or upgrading existing equipment, choosing a trusted machinery partner can make all the difference.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Leave a Comment

Latest Posts

LANE has more than 500 successful cases and is committed to providing customers with first-class solutions, high-end machinery and equipment, and one-stop pre-sales, sales and after-sales comprehensive customer service.