How to Produce Biogas Residue Liquid Fertilizer in Small and Medium-Sized Factories

More and more farms and fertilizer producers are looking for green and affordable solutions. One popular choice today is to produce biogas residue liquid fertilizer from biogas waste. This method not only reduces pollution but also creates a useful product for crops. For small and medium-sized factories, the process does not have to be complicated. With simple machines and a clear workflow, it is possible to run stable production and get good results.

In this article, we will explain the main equipment needed, step by step, using easy language. Even if you are new to liquid fertilizer production, you can understand how to produce biogas residue liquid fertilizer in a practical and friendly way.

Biogas residue comes from biogas digesters after gas production. It still contains many nutrients that plants need. Instead of throwing it away, factories can turn it into liquid fertilizer. When you produce biogas residue liquid fertilizer, you help the environment and create extra value at the same time.

Small and medium-sized factories are ideal for this work because they can start with simple equipment and slowly upgrade as demand grows.

The first step is preparing the biogas residue. This part is very important because clean material makes later steps easier.

Most factories start with a solid-liquid separator. This machine separates large solids from the liquid part. It helps protect other machines and improves product quality. To produce biogas residue liquid fertilizer smoothly, this step should never be skipped.

After separation, a simple crushing or stirring machine is often used. Its job is to break down any remaining solids so the mixture becomes more even. Some factories also use a basic screen to remove stones or unwanted items.

Fermentation helps improve the fertilizer and reduce bad smells. It also makes nutrients easier for plants to absorb. To produce biogas residue liquid fertilizer with better quality, fermentation is highly recommended.

Small factories often use:

These tanks do not need to be complex. As long as the material can be mixed and left for enough time, the process will work well.

After fermentation, the liquid is moved to a mixing tank. Here, factories can add other helpful materials, such as extra nutrients or organic additives. This step allows producers to produce biogas residue liquid fertilizer that fits different crop needs.

Mixing tanks usually have:

The operation is simple and easy to learn, which is perfect for small and medium-sized factories.

Dual Filter for Clean Liquid

Before using or selling the fertilizer, it should be filtered. Filtering removes small particles and makes the liquid smoother. This is especially important if farmers want to use the fertilizer with spraying or drip systems.

To produce biogas residue liquid fertilizer that customers trust, factories often use:

These machines are easy to clean and do not require special skills to operate.

Optional Cleaning and Stabilizing Equipment

Some factories choose to add light cleaning steps to make the fertilizer last longer. This is helpful when products need to be stored or shipped far away.

Common options include:

They help reduce unwanted bacteria while keeping nutrients safe. With these systems, it becomes easier to produce biogas residue liquid fertilizer for the market.

Storage and Filling Equipment

Once the fertilizer is ready, it needs proper storage. Most factories use plastic or steel tanks to store the finished liquid. These tanks should be clean and easy to drain.

For selling products, filling machines are very useful. Even simple semi-automatic fillers can greatly improve speed and accuracy. To produce biogas residue liquid fertilizer efficiently, this stage helps save time and labor.

Typical equipment includes:

In addition to main machines, some small tools are also important. Pumps move liquid between tanks. Pipes connect the system. Basic meters help check liquid levels.

All these parts work together to help factories produce biogas residue liquid fertilizer in a smooth and safe way.

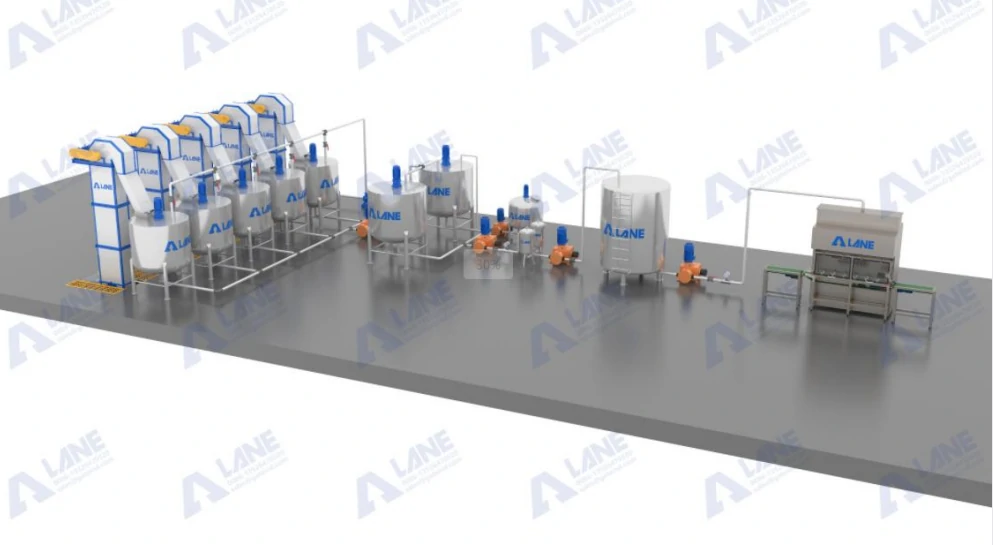

At LANE, we have spent over 20 years working with fertilizer equipment. Our company understands the real needs of small and medium-sized producers. We help customers who want to produce biogas residue liquid fertilizer by offering simple, reliable solutions.

We design and make fertilizer machines in China and support full production lines. Our team helps with planning, equipment making, installation, and after-sales service. LANE follows ISO 9001 and CE quality standards, so customers can feel confident using our machines. From organic fertilizer lines to compound fertilizer equipment, we work closely with clients to build systems that match their budget and goals.

One big advantage for small and medium factories is flexibility. You can start with basic machines and add more later. As demand increases, it becomes easier to expand and produce biogas residue liquid fertilizer on a larger scale.

Good planning and the right equipment partner can save money and avoid problems in the future.

Turning biogas residue into liquid fertilizer is a smart and eco-friendly choice. With simple equipment and a clear process, small and medium-sized factories can successfully produce biogas residue liquid fertilizer that farmers truly need. By focusing on easy operation, steady quality, and practical machines, this business can grow in a stable and sustainable way.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Leave a Comment

LANE has more than 500 successful cases and is committed to providing customers with first-class solutions, high-end machinery and equipment, and one-stop pre-sales, sales and after-sales comprehensive customer service.