How Organic Protein Liquid Fertilizer for Vegetables Is Made with Modern Equipment

Producing organic protein liquid fertilizer for vegetables has become a key trend in modern farming. Farmers want easy, safe, and effective ways to feed their plants. Liquid fertilizers are perfect because they deliver nutrients quickly and evenly. With modern production equipment, making high-quality organic protein liquid fertilizer for vegetables is easier, faster, and more reliable than ever. In this article, we will explore the production equipment, working principles, advantages, and why LANE equipment is trusted worldwide.

Vegetables need nitrogen, phosphorus, potassium, and other nutrients to grow healthy. Organic protein liquid fertilizer for vegetables is rich in these nutrients and contains proteins that help plants develop strong roots and leaves. Unlike chemical fertilizers, organic protein liquid fertilizers improve soil quality and microbial activity. Farmers using this fertilizer notice greener leaves, stronger stems, and better fruit production.

Liquid fertilizer is also easy to apply. Instead of spreading powder or granules, farmers can mix it with water and apply it directly to the soil or as a foliar spray. This ensures every plant gets the right nutrients, reduces waste, and saves time.

The first stage of production is mixing. Modern liquid fertilizer equipment includes stainless-steel mixing tanks. These machines blend protein sources, humic acid, amino acids, and other essential nutrients into a smooth, homogeneous liquid.

Proper mixing is crucial. If the ingredients are uneven, some vegetables may get too much or too little of a nutrient. With high-speed mixers, each liter of organic protein liquid fertilizer for vegetables contains a balanced nutrient profile.

Many mixers have adjustable speed and time settings, allowing operators to create different formulas for various vegetable types. For example, leafy greens may need higher nitrogen, while fruiting vegetables may need more potassium.

After mixing, the fertilizer passes through a filtration system. Dual filters remove solid particles and impurities that could clog irrigation systems. The filtration equipment is designed to handle large volumes without frequent cleaning.

Smooth, pure organic protein liquid fertilizer for vegetables flows easily through drip lines and sprayers. This ensures precise nutrient delivery to each plant. Farmers find this step saves labor and reduces maintenance of their irrigation systems.

Some advanced systems even have multi-layer filters to remove very fine particles. This is especially useful for hydroponic farms, where clogging can disrupt the entire system.

The filtered liquid is stored in tanks. These stainless-steel storage tanks maintain a stable temperature and prevent microbial growth. Sensors in the tanks monitor pH, temperature, and other important parameters.

Maintaining proper conditions ensures that organic protein liquid fertilizer for vegetables stays effective for weeks or months. Some tanks have heating systems to keep the liquid at an optimal temperature in cold climates, while others have cooling features for hot regions.

LANE’s tanks are designed with insulation and automatic monitoring. This reduces the need for manual checks and helps farmers focus on other tasks.

Modern liquid fertilizer equipment often comes with control panels. Operators can adjust nutrient ratios, mixing speed, and flow rate. This flexibility is important for producing organic protein liquid fertilizer for vegetables for different crops.

For instance, greenhouse tomatoes may require more protein and potassium, while lettuce needs more nitrogen. With an automated system, the production line can quickly switch formulas without stopping.

Automation also improves consistency. Every batch of fertilizer is nearly identical, which is crucial for commercial vegetable farms where quality must be uniform.

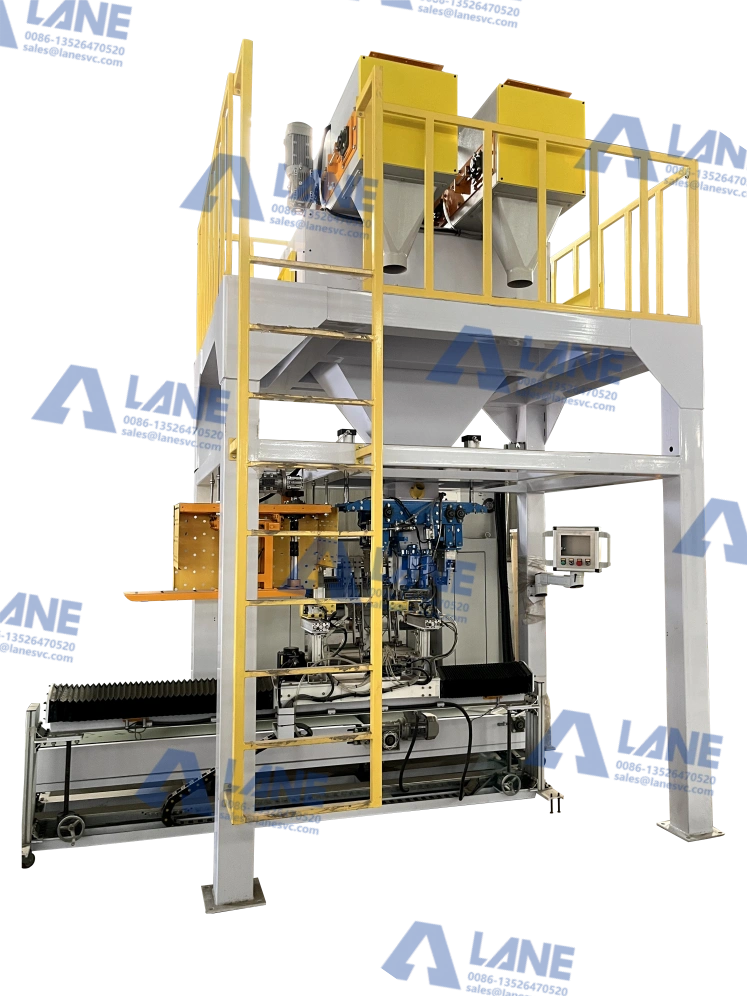

After production, the liquid fertilizer is ready for packaging. Some facilities store it in large tanks for bulk distribution, while others fill smaller containers for retail sales. Modern equipment can automate this process, filling and sealing bottles with minimal human intervention.

Farmers using organic protein liquid fertilizer for vegetables appreciate the convenience of pre-packaged solutions. It reduces waste, ensures correct dosage, and makes transportation easier.

Producing liquid fertilizer with modern equipment has many environmental advantages. Closed-loop systems recycle water and nutrients, reducing waste. Farmers applying organic protein liquid fertilizer for vegetables notice healthier crops without harming the soil.

Economically, liquid fertilizers reduce labor and application costs. They minimize losses during transport and application, making the production process more cost-effective.

Not all production lines are the same. Farmers should consider capacity, automation level, and maintenance requirements. For small farms, a compact production line with basic mixing and filtration is sufficient. Large commercial farms benefit from fully automated systems with advanced sensors and nutrient adjustment capabilities.

LANE provides various options tailored to different scales. Our machines are ISO9001 and CE certified, ensuring reliability. With over 20 years of experience, we design production lines that meet farmers’ needs while ensuring high-quality organic protein liquid fertilizer for vegetables.

At LANE, we have been specializing in fertilizer machinery manufacturing for more than 20 years. Our professional engineering team can design, manufacture, and install complete production lines. We offer full-scale support, including maintenance, troubleshooting, and upgrades, so your production line operates efficiently.

Our machines are versatile. They can produce NPK fertilizers, organic fertilizers, compound fertilizers, and organic protein liquid fertilizer for vegetables. With LANE, farmers and businesses get reliable equipment, international quality standards, and one-stop service for all their production needs.

Farmers around the world use LANE’s equipment. In greenhouse farms, organic protein liquid fertilizer for vegetables improves leaf color, fruit quality, and overall yield. In open-field vegetable farms, it enhances soil health while delivering nutrients effectively.

Some farms use automated tanks to mix customized fertilizer formulas for different crops daily. This flexibility would be difficult without modern equipment. LANE’s machines make it simple and practical.

LANE designs equipment with easy maintenance in mind. Farmers can clean mixers, filters, and tanks with minimal effort. Our support team is always available to guide users through troubleshooting or upgrades. This ensures organic protein liquid fertilizer for vegetables production continues without delays.

Making organic protein liquid fertilizer for vegetables is now faster, safer, and more efficient thanks to modern production equipment. LANE’s 20+ years of experience, certified machines, and professional support make the process smooth and reliable. Farmers benefit from consistent quality, eco-friendly operations, and higher crop yields.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Leave a Comment

LANE has more than 500 successful cases and is committed to providing customers with first-class solutions, high-end machinery and equipment, and one-stop pre-sales, sales and after-sales comprehensive customer service.