Optimizing Rice Cultivation with a Rice-Specific Liquid Fertilizer Production Line

In rice cultivation, providing the right nutrients at the right time in the right form is crucial for maximizing yield and improving crop quality. The rice-specific liquid fertilizer production line offers targeted solutions to produce high-quality liquid fertilizers, thereby promoting rice growth and soil health. Unlike traditional granular fertilizers, liquid fertilizers can quickly absorb nutrients, making them an ideal choice for rice cultivation as it requires precise fertilization throughout the entire growth cycle. In this article, we will explore the working principle of the rice-specific liquid fertilizer production line, its advantages, and how LANE’s advanced solutions can help farmers produce liquid fertilizers to achieve the best rice cultivation.

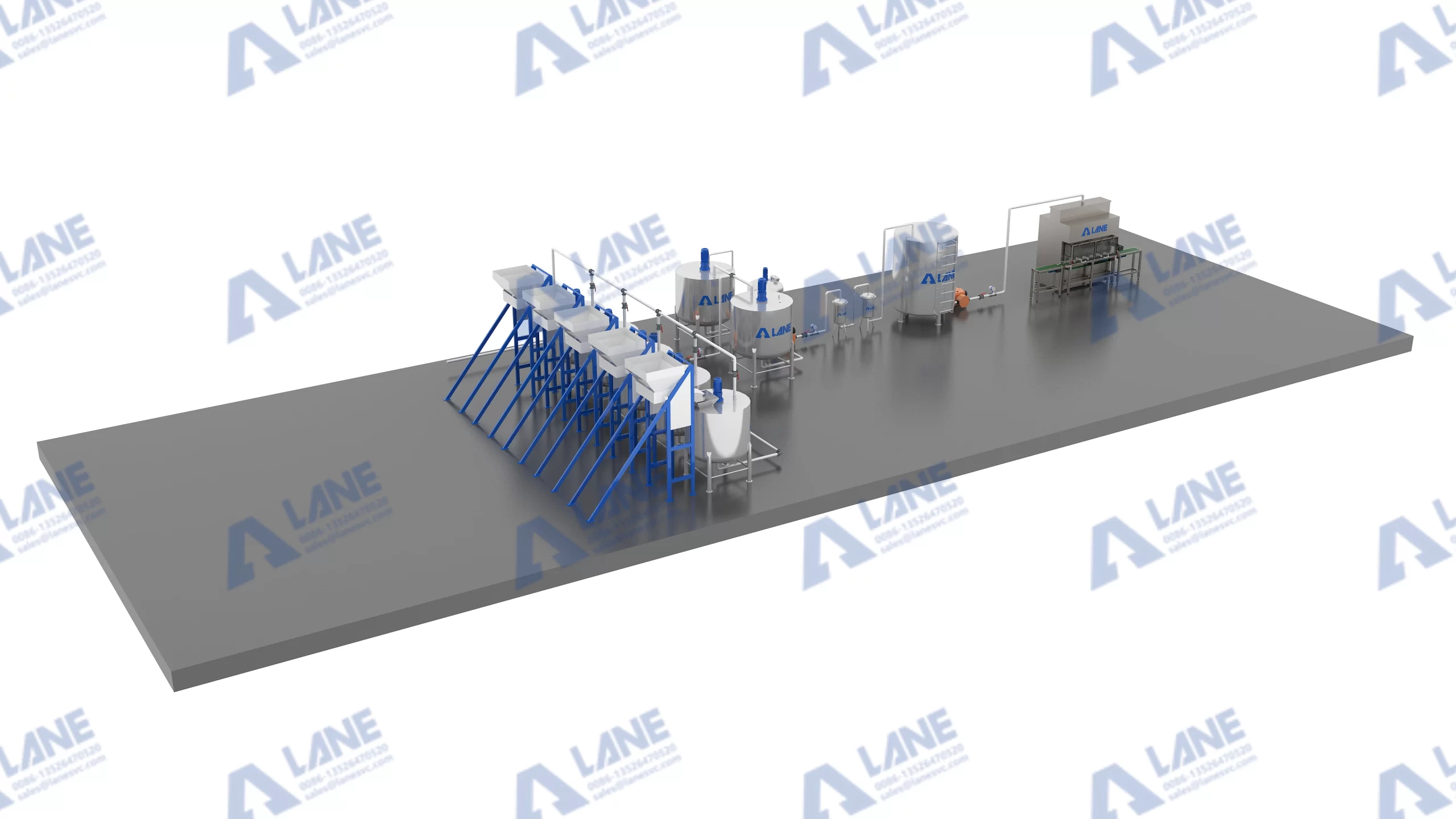

The rice-specific liquid fertilizer production line is a set of integrated equipment specifically designed for the growth needs of rice. This production line usually includes a mixing, processing and packaging system, which is used to produce liquid fertilizers rich in the essential nutrients required for rice growth. The liquid fertilizer provides nutrients in a highly soluble and easily absorbable form, ensuring that rice can quickly absorb essential elements such as nitrogen, phosphorus, and potassium, as well as trace elements such as iron and zinc.

This production line typically includes several key components, such as:

Raw Material Preparation: The initial stage involves gathering high-quality organic and inorganic raw materials to create the fertilizer formula.

Mixing System: The raw materials are blended together in a precise ratio to ensure an even distribution of nutrients.

Filtration and Purification: Any impurities or solid particles are removed to ensure a pure liquid fertilizer.

Liquid Fertilizer Production: The mixture is processed to create a liquid solution that can be easily applied to rice fields.

Packaging System: Once the liquid fertilizer is ready, it is packaged in appropriate containers for easy transport and application.

By using a rice-specific liquid fertilizer production line, farmers can ensure that their crops receive a nutrient-rich solution that supports healthy growth, reduces nutrient runoff, and promotes overall productivity.

Choosing to invest in a rice-specific liquid fertilizer production line for rice can bring numerous benefits to rice farmers, providing targeted solutions that enhance crop yields while maintaining soil health and sustainability. Let’s take a closer look at the advantages of using liquid fertilizers in rice cultivation:

Faster Nutrient Absorption: One of the main advantages of liquid fertilizer is that it can be quickly absorbed by rice plants. Unlike solid fertilizers that need time to decompose in the soil, liquid fertilizer can be immediately absorbed by the plant roots. This results in faster and more efficient nutrient delivery, especially during crucial growth stages such as flowering and grain filling.

Improved Fertilizer Efficiency: Liquid fertilizers are more efficient than granular fertilizers because they are less likely to be lost through runoff or leaching. When applied correctly, liquid fertilizers can be directly absorbed by the plant roots or sprayed onto the leaves, thereby increasing the utilization rate of nutrients. Even with a smaller amount of fertilizer applied, plants can be healthier and yield higher.

Customizable Formulas for Rice Growth: The rice-specific liquid fertilizer production line enables farmers to customize fertilizer formulas according to the specific needs of the rice crops. For instance, during the early stage of the rice’s vegetative growth, a higher nitrogen content is required; while during the reproductive growth and maturity stages, more potassium and phosphorus are needed. With the aid of the customized fertilizer production line, farmers can tailor the ideal nutrient solution for each growth stage of the crops, ensuring that the plants receive the necessary nutrients at the right time.

Environmental Benefits: Compared with solid fertilizers, liquid fertilizers are more environmentally friendly. Since liquid fertilizers are less volatile and can be more easily absorbed by the soil, they can reduce the risk of nutrient loss into surrounding waterways. By using liquid fertilizers, farmers can minimize their environmental impact while achieving the best crop yields.

Easy Application and Management: The application of liquid fertilizers is more flexible and efficient. Liquid fertilizers can be applied through irrigation fertilization (mixing the fertilizer with irrigation water), foliar spraying, or direct root application. This flexibility helps farmers manage nutrient delivery more precisely, ensuring that nutrients reach the plants at the time when they are most needed.

The rice-specific liquid fertilizer production line consists of several essential components that work together to produce a high-quality liquid fertilizer. Each piece of equipment plays a critical role in ensuring the efficiency and effectiveness of the final product.

(1) Raw Material Preparation System

The first step in the production process is the preparation of the raw materials. This includes the selection of organic and inorganic ingredients that will provide essential nutrients such as nitrogen, phosphorus, potassium, calcium, and micronutrients. Quality control during this stage ensures that the raw materials are pure and free of contaminants, which is crucial for producing effective fertilizers.

(2) Blending and Mixing System

After the raw materials are prepared, they are mixed together in a precise ratio to create the nutrient solution. The stainless steel mixing tank ensures that the fertilizers are evenly blended, preventing any uneven distribution of nutrients in the final product. Advanced mixing technology can create a homogeneous liquid fertilizer solution that is ideal for rice plants.

(3) Filtration and Purification System

After the mixture is completed, the liquid fertilizer will pass through a dual filter for purification, removing any undissolved solids or impurities. This purification process ensures that the fertilizer does not contain any components that may clog the fertilizing equipment or hinder the soil’s absorption of nutrients.

(4) Fertilizer Production and Processing

The production process involves further processing to ensure the nutrients are fully dissolved in the liquid. Specialized equipment ensures that the fertilizer maintains a balanced nutrient profile while achieving the desired concentration. This is important for ensuring consistent performance and effectiveness when the fertilizer is applied.

(5) Packaging System

Once the liquid fertilizer is produced, it is packaged into containers suitable for transport and application. The automatic packaging system must ensure that the liquid fertilizer is stored in leak-proof and durable containers that protect the product from contamination. This system often includes automated filling, sealing, and labeling to streamline the packaging process.

A rice-specific liquid fertilizer production line offers numerous benefits to rice farmers, from improving nutrient absorption to reducing environmental impact. By investing in a customized production line, farmers can ensure their crops receive the right nutrients at the right time, boosting productivity and improving soil health. With LANE’s cutting-edge equipment, farmers can enjoy the benefits of a highly efficient, durable, and environmentally friendly fertilizer production process.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Leave a Comment

LANE has more than 500 successful cases and is committed to providing customers with first-class solutions, high-end machinery and equipment, and one-stop pre-sales, sales and after-sales comprehensive customer service.