Nutrient Liquid Fertilizer Guide: Raw Materials, Additives, and Production Systems

In modern agriculture, nutrient liquid fertilizer has quietly moved from a supporting role to a central position. It fits today’s farming style very well. It is easy to store, easy to transport, and easy to apply. More importantly, it works fast and evenly, which is exactly what growers want.

Behind this smooth and flowing product is a long production chain. Raw materials must be chosen carefully. Auxiliary materials must be added at the right time. Equipment must work reliably day after day. In this article, we will walk through all of these steps in a clear and relaxed way, focusing on what really matters in production.

Before talking about materials, it helps to understand what liquid fertilizer really is. Nutrient liquid fertilizer is plant nutrition dissolved or suspended in water. Because it is already in liquid form, plants can absorb it more quickly than solid products.

This type of fertilizer is widely used in drip irrigation, spraying systems, and foliar feeding. It allows precise control of nutrients and reduces waste. That is one reason why both large farms and small growers are paying more attention to it.

Every production line starts with raw materials. In nutrient liquid fertilizer manufacturing, these materials mainly come from organic and mineral sources. The combination depends on local availability, crop needs, and production goals.

From our long-term work with fertilizer producers, we have learned that flexibility is key. A good production system should adapt to materials, not force materials to adapt to machines.

Animal-based materials are widely used in nutrient liquid fertilizer production. Common examples include cattle manure, chicken manure, fish waste, and other animal processing residues.

These materials are rich in nitrogen and organic matter. However, they usually have high moisture content and strong odor. That is why proper fermentation and separation are essential.

In many projects, we help customers turn local animal waste into stable liquid products. By designing suitable processing steps, these materials become valuable inputs instead of disposal problems.

Plant-based materials offer another important source for nutrient liquid fertilizer. Crop residues, plant extracts, molasses, food waste, and seaweed are all commonly used.

Seaweed extract is especially popular because it contains natural compounds that support plant growth and stress resistance. Plant materials are generally easier to break down and blend well into liquid systems.

From practical experience, plant-based formulas perform best when mixing and extraction are gentle but consistent. This helps keep nutrients evenly distributed.

Organic materials alone may not meet all crop needs. That is why mineral inputs are often added to nutrient liquid fertilizer.

These include nitrogen solutions, potassium sources, phosphorus compounds, and trace elements such as iron or zinc. Minerals help producers adjust nutrient ratios and improve consistency.

The key is control. Accurate dosing and stable mixing systems help avoid uneven products and quality fluctuations.

Auxiliary materials do not provide major nutrients, but they strongly influence product quality. In nutrient liquid fertilizer, these materials include microbial agents, stabilizers, chelating agents, and pH regulators.

Microbial agents support fermentation and improve nutrient availability. Stabilizers prevent settling during storage. Chelating agents keep trace elements active in liquid form. pH control protects both crops and equipment.

Although these ingredients are used in small quantities, they must be handled carefully during production.

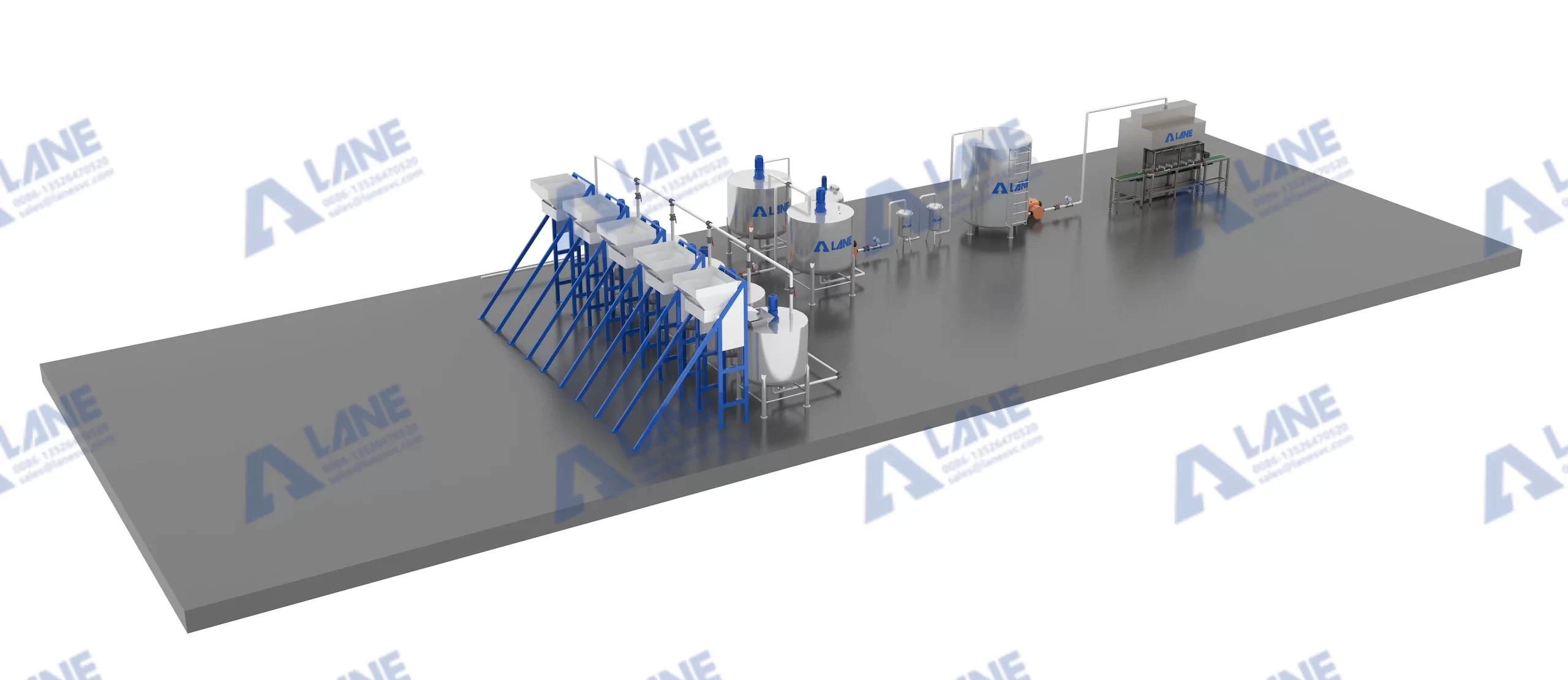

No matter how good the formula is, poor equipment can ruin it. Nutrient liquid fertilizer production depends heavily on reliable machines and smart process design.

Over the years, we have seen that stable output comes from matching equipment to materials. That is why equipment selection is never random. It is based on real operating conditions and long-term performance.

The Inclined Dewatering Machine is often one of the first key machines in the line. It is designed to handle high-moisture organic materials, especially after fermentation.

Its inclined structure allows water to drain naturally while solids move upward. This reduces moisture content efficiently and continuously.

In many production lines we support, this machine helps improve material consistency and reduce the load on downstream equipment.

For nutrient liquid fertilizer, liquid clarity and stability are very important. The Liquid-Liquid Centrifugal Extractor plays a major role here.

By using centrifugal force, it separates different liquid phases based on density. This removes impurities and improves the appearance and stability of the final product.

From real production feedback, proper centrifugal extraction reduces storage problems and improves market acceptance.

The Screw Extrusion Dehydrator is used to further process solid residues. It applies mechanical pressure to squeeze out remaining liquid.

This machine improves overall material utilization. Extracted liquid can return to the system, while solids can be reused or processed separately.

In many customized lines, this step helps customers reduce waste and improve efficiency.

Every nutrient liquid fertilizer formula behaves differently. Some materials are thick. Others are light. Some ferment quickly. Others need time.

That is why we always focus on customization. Our engineering team designs complete production lines based on real materials and output goals. Installation, testing, and long-term service are all part of the process.

This approach helps customers avoid common production issues and maintain stable operation.

A good liquid fertilizer must stay stable from production to application. Nutrient liquid fertilizer should not separate, settle, or lose activity during storage.

Quality control includes checking nutrient content, pH, viscosity, and microbial activity. Reliable tanks, mixers, and control systems make these checks easier and more accurate.

Stable products build trust with farmers and distributors alike.

The future of nutrient liquid fertilizer is closely linked to sustainability. It allows producers to recycle organic waste and reduce reliance on solid products.

With the right raw materials, supporting ingredients, and well-designed equipment, liquid fertilizer production can be efficient, flexible, and environmentally friendly.

We see this trend growing year by year, and we are proud to support it through practical machinery solutions, customized production lines, and dependable after-sales service that keeps production running smoothly.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Leave a Comment

Latest Posts

LANE has more than 500 successful cases and is committed to providing customers with first-class solutions, high-end machinery and equipment, and one-stop pre-sales, sales and after-sales comprehensive customer service.