Turnkey vs. Custom-Built: Choosing the Right NPK Liquid Fertilizer Production Line for Your Business

NPK Liquid Fertilizer offers faster nutrient absorption, precise nutrient control, and easier application to the farmers. It is easier to apply than traditional solid fertilizers. Modern agriculture prioritizes efficiency and crop yield, because of this the demand for high-quality NPK Liquid Fertilizer continues to soar. For entrepreneurs looking to enter this market, choosing the right production line is critical.

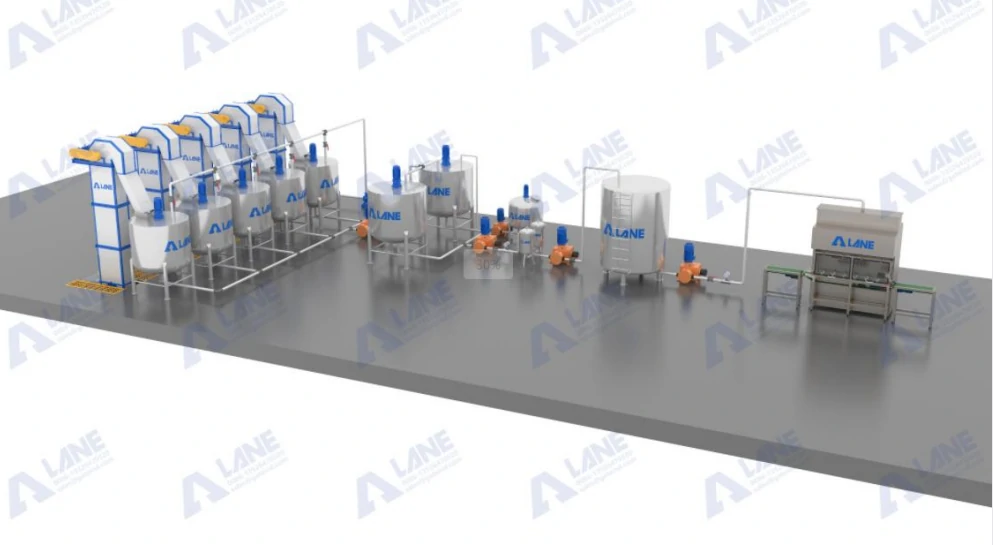

The decision for an NPK liquid fertilizer production line always comes down to turnkey vs. custom-built solutions. The choice is between immediate operational readiness and long-term strategic fit. Sometimes upfront cost, deployment speed, and unique formulation requirements are also decisive factors. LANE Heavy Industry Machinery offers solutions across this spectrum, from ready-to-install systems to fully tailored projects, making it essential to align your choice with your specific business goals.

Table of Contents

In manufacturing, the decision often boils down to custom-built or ready-built. For an NPK liquid fertilizer production line, this means two paths.

A turnkey solution is a pre-designed, integrated system that is ready for manufacturing and installation. Suppliers like LANE Heavy Industry offer these complete lines with defined capacities (e.g., 1-30 tons per hour) with standardized processes, and a fixed set of features. The major advantage of a turnkey NPK Liquid Fertilizer production line is its reduced risk and faster deployment. The system’s design and integration are already proven and managed by the supplier.

A custom-built production line is designed and engineered from the ground up to meet a producer’s unique specifications. This approach is necessary when standard solutions cannot accommodate unique raw materials, proprietary formulations, specialized automation, or unconventional facility layouts.

The following table breaks down the core differences between the two approaches, informed by industry practices and the services offered by machinery providers.

| Feature | Turnkey NPK Liquid Fertilizer Production Line | Custom-Built NPK Liquid Fertilizer Production Line |

| Core Philosophy | Standardized, “off-the-shelf” solution. | Bespoke, designed for a unique “project”. |

| Design & Flexibility | Limited customization; adapts to the machine. | High flexibility; machine is built around your exact process. |

| Lead Time & Deployment | Shorter; uses pre-engineered designs and modules. | Significantly longer; involves full design, prototyping, and testing phases. |

| Upfront Cost | Generally lower and more predictable. | Substantially higher due to engineering and one-off manufacturing. |

| Risk & Reliability | Lower risk; the system is pre-tested and proven. | Higher technical and timeline risk; unique systems are untested. |

| Technical Support | Streamlined; support is for a known system. | Can be complex but deeply integrated with the original design team. |

| Ideal For | New entrants, businesses with standard NPK formulations, rapid scale-up needs. | Established producers with patented formulas, unique raw materials, or who compete on specialized products. |

Sometimes customers need a middle ground. This led to LANE Heavy Industry offering a third way: the modified turnkey solution. This involves starting with a proven, standard production line platform and then applying specific customizations.

For example, LANE Heavy Industry helps customers with customization options such as adjusting the core components, automation degree, voltage, and capacity. This approach allows you to benefit from the reliability and faster delivery of a turnkey system.

To determine which path is right for you, work through these questions:

What is your budget and timeline?

If capital is limited and you need to start production within 3-6 months, a turnkey solution is the better choice.

How unique is your NPK formulation?

If you are producing a standard 20-20-20 liquid fertilizer, a turnkey line is sufficient. If your recipe involves complex chelation, unusual nutrient sources, or specific stabilizers, you might need a custom design.

What is your in-house technical capability?

Turnkey solutions provide you with guidance, on-site installation, and worker training. LANE also offers video guidance when you face a technical problem as after-sales service. LANE also offers the same service for custom projects. A custom project requires deep internal engineering awareness and understanding.

What are your long-term scaling plans?

You must consider future capacity. Some turnkey lines are modular, while a custom design can explicitly build in scalability from the start.

Regardless of your choice, partnering with an experienced supplier is critical. LANE Heavy Industry Machinery has experience supplying large-scale national projects. We provide service to both ends of the spectrum.

For the turnkey buyer, we offer complete, certified (CE, ISO) lines with clear capacity ratings and comprehensive after-sales support. We offer a 5-year warranty on some lines.

For custom project clients, we offer “full customization services,” “3D software design,” and the ability to handle everything from specific raw materials to final pellet size based on your instructions.

To learn more about our solutions you can directly contact our technical sales team.

Choosing between a turnkey and custom-built NPK Liquid Fertilizer production line ultimately depends on your business goals, budget, and timeline. If you are a startup or small business looking to launch quickly, a turnkey line from LANE Heavy Industry is the ideal choice. If you have a specialized formula and want to stand out in the market or plan for long-term growth, a custom-built line will offer the flexibility and efficiency you need.

There is no universally best type of NPK liquid fertilizer production line. Only the best for your business at your current stage. By carefully weighing your formulation needs, financial constraints, and strategic goals against the clear differences outlined here, you can make a confident investment in the production infrastructure that will propel your business forward.

Q1: I’m new to fertilizer production. Can a supplier really guide me through the entire process?

Yes, reputable suppliers like LANE Heavy Industry are equipped for this. For beginners entering NPK Liquid Fertilizer production, suppliers typically ask about your raw materials, desired capacity (tons/hour), and final product specifications. Based on this information, their engineers will help select and configure the appropriate machinery to match your specific production goals.

Q2: How do I handle maintenance and repairs if I don’t have a technical team?

This is a key advantage of turnkey solutions, especially for NPK Liquid Fertilizer plants. Suppliers usually provide online technical support, remote video guidance, and detailed operation manuals. For more complex issues, engineers can be dispatched on-site. Choosing equipment with a long warranty period (such as 5 years) further reduces operational risk and protects your initial investment.

Q3: If I choose a custom line, how involved do I need to be in the design?

Very involved. When building a customized NPK Liquid Fertilizer production line, you will work closely with the supplier’s engineering team to define every critical parameter, including chemical process flow, material handling specifications, automation control logic (PLC programming), and safety systems. This close collaboration ensures the final plant operates efficiently, safely, and cost-effectively.

Q4: Can I upgrade a turnkey line later if my needs change?

It depends on the initial design’s modularity. Many modern lines are built with some flexibility. Discuss future scalability needs with your supplier upfront. While adding completely new processes later can be challenging, increasing capacity or adjusting parameters within the system’s design envelope is often possible.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Leave a Comment

Latest Posts

LANE has more than 500 successful cases and is committed to providing customers with first-class solutions, high-end machinery and equipment, and one-stop pre-sales, sales and after-sales comprehensive customer service.