Mixing Tank with Agitator for Liquid Fertilizer Projects: Process Role and Structural Understanding

Liquid fertilizer production looks simple on the surface. Raw materials are added, mixed, and then stored or packed. In reality, the stability of the product depends strongly on the early mixing stage. A mixing tank with agitator is the main equipment used to complete this task.

In many production lines, problems such as sediment, uneven concentration, or unstable appearance are not caused by raw materials. They are often caused by insufficient mixing. This is why mixing equipment is considered a core unit rather than a supporting one. Understanding its role helps producers improve both quality and efficiency.

Liquid fertilizer usually contains water, macro nutrients, trace elements, and sometimes organic components. These materials behave differently in liquid form. Some dissolve quickly. Others need time and motion.

A mixing tank with agitator provides controlled movement. This movement allows materials to contact each other evenly. It also prevents heavier components from settling at the bottom. Without this process, the fertilizer cannot maintain uniform composition during storage or use.

From practical production experience, stable mixing is one of the foundations of a reliable fertilizer line.

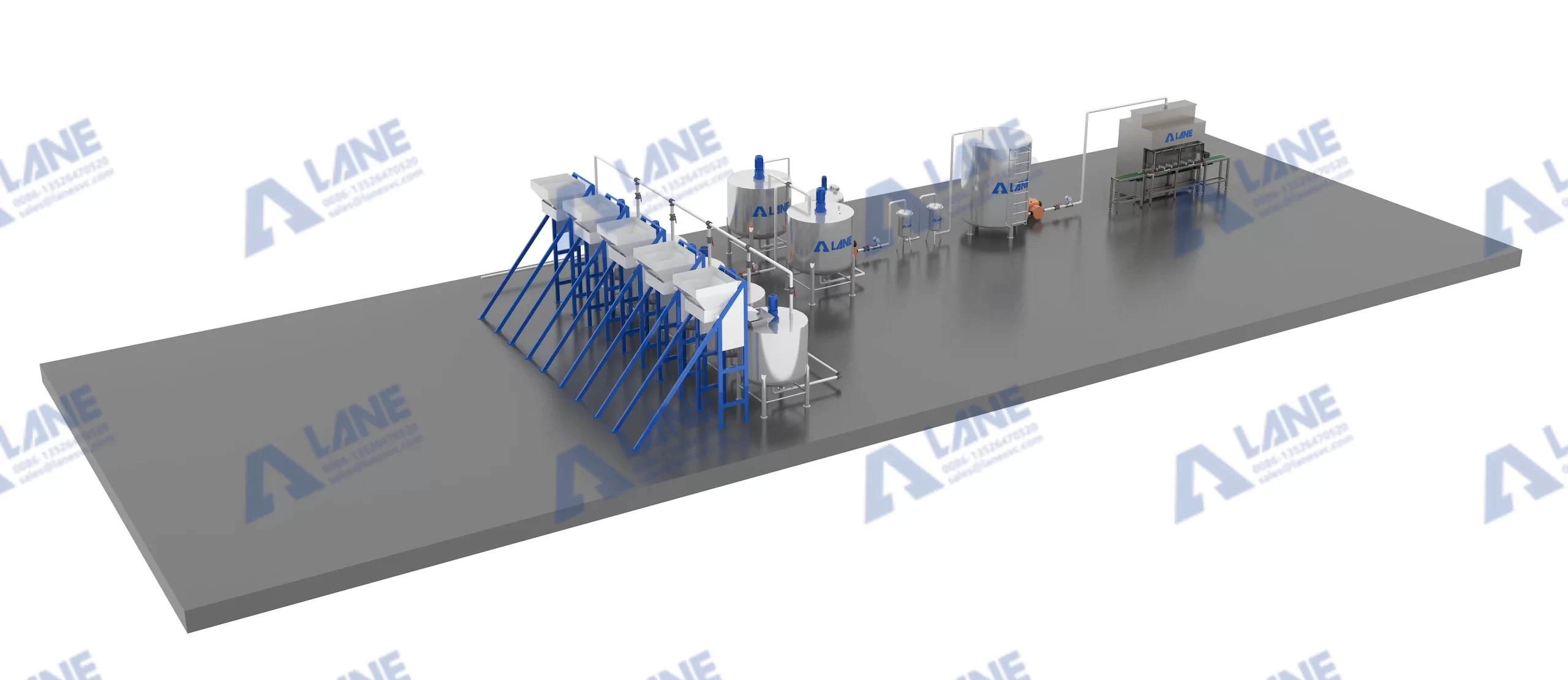

In a typical liquid fertilizer production line, the mixing tank with agitator is installed after raw material dosing and before filtration or storage. At this stage, materials enter the system in a short time window.

The tank acts as a buffer and processing unit. It absorbs fluctuations from upstream feeding and provides stable flow to downstream equipment. When the mixing stage is stable, the entire line becomes easier to control.

In complete production line projects, correct positioning of the mixing tank often reduces later operational adjustments.

The structure of a mixing tank with agitator is relatively simple, but each part has a clear purpose. The main body is usually cylindrical. This shape supports smooth internal circulation.

The tank body holds the material and provides volume for mixing. It may include nozzles for feeding, discharge ports, and inspection openings. The inner surface is designed to reduce residue buildup, which helps with cleaning and maintenance.

Although the structure looks straightforward, design details strongly affect performance during long-term operation.

The agitator is the active part of a mixing tank with agitator. It creates flow inside the tank by rotating blades or paddles. This flow moves materials both vertically and horizontally.

The goal is not violent stirring. The goal is stable circulation. Good mixing keeps solids suspended and liquids blended without introducing too much air. This balance is achieved by selecting proper blade shape, speed, and installation height.

In real projects, agitator parameters are often adjusted during commissioning to match actual material behavior.

Liquid fertilizers can be mildly or highly corrosive. For this reason, material selection is an important part of mixing tank with agitator design.

Carbon steel is suitable for many general formulations. Stainless steel is preferred for products with higher corrosion risk or purity requirements. The choice affects service life, maintenance frequency, and cleaning effort.

From equipment manufacturing experience, surface treatment and welding quality are just as important as base material choice.

Uniform mixing means uniform fertilizer quality. A mixing tank with agitator ensures that nutrients are evenly distributed throughout the liquid.

If mixing is uneven, concentration differences appear. These differences may not be visible at first but become clear during storage or application. Improving mixing performance often solves these issues without changing the fertilizer formula itself.

This is why mixing quality is closely linked to customer satisfaction in the fertilizer market.

Liquid fertilizers are not all the same. Some are clear solutions. Others contain suspended solids or organic matter. A mixing tank with agitator must adapt to these differences.

Mixing time, speed, and tank volume are adjusted according to material properties. In some production lines, insulation or heating is added to support dissolution. Flexibility in design allows one system to handle multiple products.

This adaptability is especially important for producers with diverse product ranges.

The mixing tank is connected to pumps and pipelines. A mixing tank with agitator must provide stable outlet conditions to avoid pressure fluctuation.

Stable discharge protects pumps and valves. It also ensures consistent feeding to downstream units such as filters or storage tanks. Good integration reduces wear and improves overall line efficiency.

In full production line installations, coordination between mixing and transfer systems is often optimized during on-site adjustment.

Daily operation of a mixing tank with agitator should be simple. Operators mainly control mixing time, speed, and liquid level. Clear control logic reduces the chance of human error.

Maintenance focuses on mechanical components such as bearings, seals, and motors. Easy access to these parts shortens maintenance time. Based on long-term service experience, simple structure often leads to higher reliability.

Well-planned maintenance helps avoid unexpected downtime.

In continuous liquid fertilizer production, the mixing tank with agitator plays a stabilizing role. It smooths fluctuations from raw material feeding and supports steady output.

As a buffer unit, it allows the production line to run for long periods without interruption. This improves efficiency and reduces waste caused by off-spec products.

Stable mixing is therefore closely linked to overall production performance.

From more than 20 years of work in fertilizer machinery projects, it is clear that mixing systems are rarely identical. Equipment is often customized to match production scale and material behavior.

Professional engineering teams usually handle design, installation, and commissioning together. Compliance with international standards such as ISO9001 and CE provides a reliable technical foundation for safety and quality.

This combination of experience and standards supports long-term stable operation.

Although it appears simple, the mixing tank with agitator has a deep influence on liquid fertilizer production. It affects product uniformity, process stability, and equipment coordination.

By understanding its structure and role, producers can make better decisions in production line design and operation. Practical experience shows that reliable mixing is not an added feature, but a basic requirement for consistent and efficient liquid fertilizer manufacturing.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Leave a Comment

LANE has more than 500 successful cases and is committed to providing customers with first-class solutions, high-end machinery and equipment, and one-stop pre-sales, sales and after-sales comprehensive customer service.