Maximizing Crop Yields with Liquid Fertilizer from Food Waste

Liquid fertilizer from food waste is rapidly emerging as one of the most promising solutions in sustainable agriculture. By converting discarded food into nutrient-rich plant liquid fertilizer, farmers, municipal authorities, and enterprises can reduce landfill waste, decrease greenhouse gas emissions, and provide environmentally friendly sources of nutrition for crops.

This method not only addresses the challenges of waste management but also supports the circular economy – substances that were once considered waste have become valuable agricultural resources. With advanced production technologies, companies like LANE are leading the way in converting food waste into stable, safe, and immediately marketable high-quality liquid fertilizers.

Every year, the world generates millions of tons of food waste. Most of this food waste is eventually buried in landfills, where it undergoes anaerobic decomposition, releasing methane – a more potent greenhouse gas than carbon dioxide. By processing food waste into liquid fertilizer, we can:

Reduce environmental impact by diverting organic matter from landfills.

Improve soil health with nutrient-rich formulations tailored for different crops.

Support local agriculture by creating affordable, sustainable fertilizer options.

In many cases, the nutrients in food waste—such as nitrogen, phosphorus, potassium, and trace minerals—are more bioavailable to plants in liquid form than in traditional solid compost or chemical fertilizers.

A modern production line for liquid fertilizer from food waste typically follows these steps:

| Step | Description | Main Equipment | Purpose |

| 1. Collection & Sorting | Gather food waste from restaurants, markets, and processing plants, removing plastics, metals, and other contaminants. | Food Waste Sorting Conveyor & Magnetic Separator | Ensure raw material purity for safe fertilizer production. |

| 2. Grinding & Pulping | Break down waste into small, uniform particles to increase surface area for microbial action. | Food Waste Crusher & Pulping Machine | Improve fermentation efficiency. |

| 3. Sterilization | Heat or chemical treatment to eliminate harmful pathogens. | UV Sterilizer | Ensure product safety for agricultural use. |

| 4. Anaerobic or Aerobic Fermentation | Use beneficial microbes to break down organic matter and release nutrients. | Anaerobic Fermentation Tank or Aerobic Fermentation Reactor | Convert food waste into nutrient-rich liquid. |

| 5. Filtration & Refining | Remove solids, grit, and impurities to create a smooth liquid product. | Dual Filter | Achieve uniform texture and prevent clogging during application. |

| 6. Formulation & Packaging | Adjust nutrient ratios, blend additives if needed, and package the product. | Liquid Fertilizer Mixing Tank & Automatic Liquid Fertilizer Filling Machine | Meet specific crop requirements and prepare for distribution. |

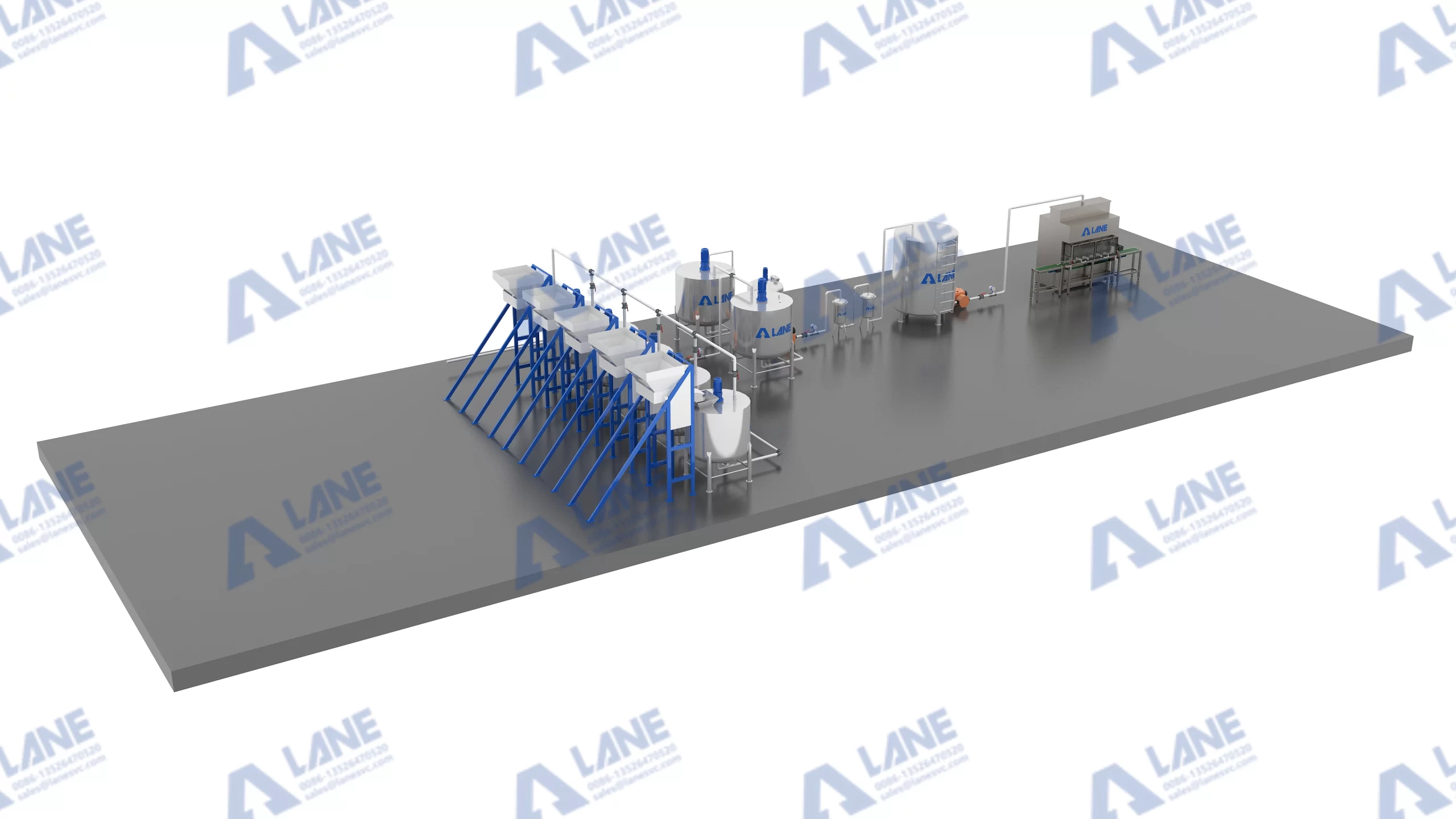

LANE offers advanced liquid fertilizer from food waste production lines designed for efficiency, safety, and scalability. Our solutions include:

High-Quality Equipment: From shredders and fermentation tanks to filtration systems, all machines are built with durable materials for long-term performance.

Automated Control Systems: Maintain optimal temperature, pH, and nutrient levels throughout the process.

Energy Efficiency: Smart designs reduce electricity and water consumption.

Full Project Support: From initial consultation and plant layout to installation, training, and after-sales service.

Custom Solutions: Tailored designs for different processing capacities—from small community projects to large industrial facilities.

LANE’s engineering team ensures that every production line meets international quality standards and delivers consistent fertilizer output with minimal environmental impact.

In a recent project, a municipal government collaborated with LANE to jointly address the increasingly severe daily challenge of kitchen waste management. The design goal of this facility was to process 20 tons of kitchen waste collected from local markets, restaurants and community centers every day.

This factory adopted LANE’s fully automated liquid fertilizer production line, including a kitchen waste shredder, fermentation tanks, filtration devices and automatic filling machines. It could convert organic waste into nutrient-rich liquid fertilizer in just 7 to 10 days.

Key results from the project included:

25% shorter processing time compared to conventional composting methods.

Consistent nutrient composition, meeting local agricultural quality standards.

7,000+ tons of waste diverted from landfill annually, significantly reducing methane emissions.

Lower operational costs thanks to energy-efficient motors and intelligent control systems.

Local farmers quickly adopted the liquid fertilizer, citing better crop vigor and improved soil moisture retention. The project not only solved a pressing waste problem but also created a reliable local fertilizer supply, reinforcing the community’s shift toward sustainable agriculture.

As climate policies tighten and the push for sustainable farming grows stronger, liquid fertilizer from food waste will become an essential part of the agricultural supply chain. With innovations in fermentation technology, nutrient extraction, and distribution, we can expect:

Higher nutrient recovery rates.

Integration with precision agriculture systems.

Wider adoption by both small-scale farmers and large commercial operations.

LANE is committed to driving this transformation by providing not just machines, but complete solutions that help communities and businesses achieve zero-waste goals while boosting agricultural productivity.

Liquid fertilizer from food waste represents a win-win solution: it addresses food waste challenges, reduces environmental harm, and delivers high-quality crop nutrition. With advanced equipment, expert guidance, and comprehensive services, LANE ensures that turning food waste into liquid fertilizer is not just possible—but profitable and sustainable.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Leave a Comment

LANE has more than 500 successful cases and is committed to providing customers with first-class solutions, high-end machinery and equipment, and one-stop pre-sales, sales and after-sales comprehensive customer service.