The Liquid Advantage: Inside a Modern Liquid Micronutrient Fertilizer Plant

While nitrogen, phosphorus, and potassium (NPK) are the mainstays of plant nutrition, the critical determinants of crop health, yield, and quality are often the micronutrients. Micronutrients—including iron, zinc, manganese, copper, boron, molybdenum, and chlorine—are essential for crop health but are often overlooked in traditional fertilization practices.

While required in minute quantities, these “trace elements” are the catalysts for essential plant processes, from enzyme activation to chlorophyll synthesis. Because of intense farming, soil deficiencies have become more prevalent. The demand for efficient and bioavailable micronutrient delivery has skyrocketed. This is where liquid micronutrient fertilizers have been introduced as a solution.

A liquid micronutrient fertilizer plant helps farmers and agribusinesses create micronutrient fertilizers that offer superior absorption, flexibility, and application efficiency. LANE Heavy Machinery, a leader in the fertilizer equipment manufacturing industry, designs and manufactures liquid micronutrient fertilizer plants for farmers and agribusinesses to meet the growing demand for micronutrient fertilizers.

Liquid fertilizers provide undeniable agronomic and operational benefits that powder or granular products cannot match.

Producing liquid micronutrient fertilizers is a complex chemical process. This process demands precision, consistency, and safety. These challenges include:

To overcome these challenges requires more than chemistry expertise. It requires durable, reliable, and precise industrial machinery. This is where LANE Heavy Industry can help you solve your problem.

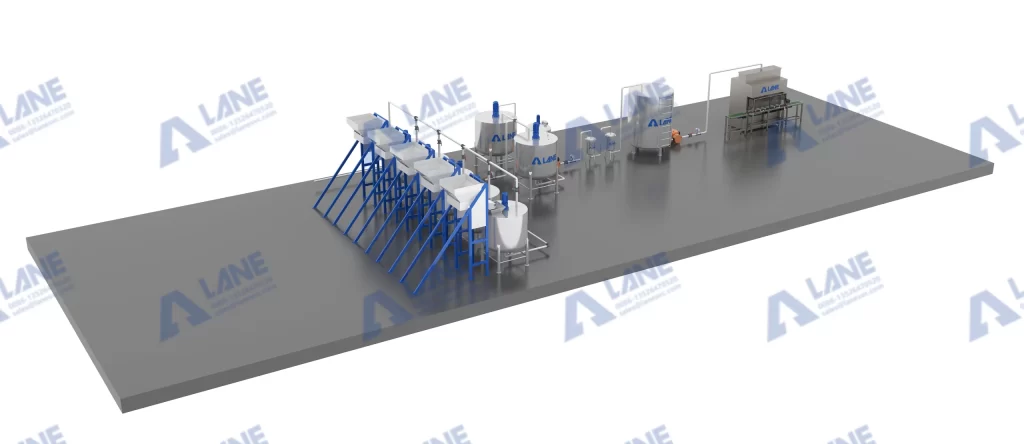

A modern liquid micronutrient fertilizer plant built by LANE Heavy Machinery features heavy-duty processing equipment built for success. LANE’s engineered solutions are integral at every stage:

LANE Heavy Machinery provides the durable, reliable industrial framework upon which the chemistry of micronutrient production depends.

A production line designed and manufactured by LANE operates harmoniously with each component.

The credibility of a liquid micronutrient fertilizer plant is determined by the consistency of its output. This consistency is achieved through automated process control systems. Producers can control the full production line with a PLC control from a central command. They can adjust parameters and pH with the click of a button.

The modern liquid micronutrient fertilizer plant is a testament to the intersection of agricultural science and industrial engineering. As agriculture continues to evolve, the role of tailored micronutrient nutrition will grow with it. By leveraging advanced technology and equipment from LANE Heavy Machinery, these plants are transforming the way we feed our crops, offering superior efficiency, flexibility, and sustainability.

Q1: What exactly is produced in a liquid micronutrient fertilizer plant?

A1:A liquid micronutrient fertilizer plant produces concentrated liquid solutions that contain essential trace elements (like zinc, boron, manganese, etc.). These nutrients are immediately available to plants. They can be single-nutrient or complex blends.

Q2: Why is heavy machinery from a company like LANE so important for this process?

A2: The chemical reactions involve corrosive materials, require precise temperature/pressure control, and must be scaled to produce thousands of gallons consistently. LANE Heavy Industry produces durable, reliable, and precise tanks, reactors, mixers, and piping systems that can withstand these demanding conditions.

Q3: Are liquid micronutrients better than granular ones?

A3: Both have their uses. Liquid micronutrients offer faster plant response, more uniform application (especially via fertigation), and better compatibility with other agrochemicals. The choice depends on specific crop needs, soil conditions, and farm logistics.

Q4: How do liquid micronutrient fertilizer plants ensure product quality?

A4: Quality control is a top priority in modern liquid micronutrient fertilizer plants. A plant designed and manufactured by LANE implements rigorous testing at every stage of production. Advanced equipment, such as LANE’s precision filtration systems and temperature-controlled mixers, helps maintain product integrity.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Leave a Comment

LANE has more than 500 successful cases and is committed to providing customers with first-class solutions, high-end machinery and equipment, and one-stop pre-sales, sales and after-sales comprehensive customer service.