How a Lean Liquid Fertilizer Production System for Greenhouse Boosts Output

Greenhouse agriculture is one of the popular agricultural systems in modern food production. It offers controlled environments to optimize crop growth year-round. But it relies heavily on quality nutrients. This makes a liquid fertilizer production system for greenhouses a critical component. It is different from traditional, generic fertilizers. This is an on-site system. This approach eliminates waste, optimizes processes, and adds value at every step, applying nutrients directly to plant nutrition.

By integrating a dedicated liquid fertilizer production system for greenhouses, growers gain full control over nutrient formulation, slash input costs, reduce environmental impact, and unlock significant increases in both crop quantity and quality. Lean production principles, combined with LANE Heavy Industry’s state-of-the-art machinery, transform the Liquid Fertilizer Production System for Greenhouses into a streamlined, cost-effective solution that directly boosts crop output. This article explores how a streamlined liquid fertilizer production system for greenhouses from LANE Heavy Industry can revolutionize productivity and give tangible benefits to greenhouse growers worldwide.

A lean production system in the context of a greenhouse means delivering the precise nutrients plants need, exactly when they need them, with minimal resource expenditure. A traditional liquid fertilizer model involves over-purchasing, storage waste, packaging disposal, and the carbon footprint of transportation. It does not offer any flexibility to tailor nutrients to specific crop stages or varieties.

An on-site liquid fertilizer production system for greenhouse applications applies lean principles by:

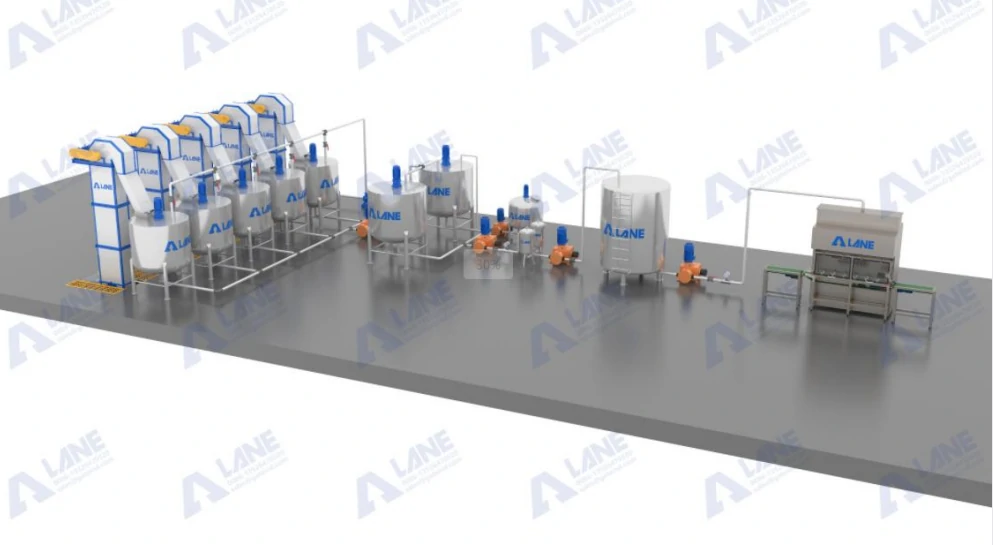

Implementing a liquid fertilizer production system for greenhouses requires reliable machinery. A complete liquid fertilizer production system for greenhouses offered by LANE Heavy Industry is:

These are the keys to a lean operation. It allows the greenhouse to pivot its recipe based on resource availability and crop demand.

The specialized liquid fertilizer production system for greenhouses follows a logical, automated sequence:

Integrating this liquid fertilizer production system for greenhouse operations requires planning. LANE can customize the scale of this system to match with your greenhouse facility’s size. For a medium to large greenhouse, a compact, skid-mounted system is often ideal.

Table: Key Components of a Lean Liquid Fertilizer Production Line for a Greenhouse

| Component | Primary Function | Lean Production Benefit |

| Mixing & Reaction Tanks | Dissolves raw materials and facilitates chemical/biological reactions. | Enables precise, small-batch production tailored to immediate crop needs (pull-based). |

| High-Shear Emulsifier | Creates a uniform, stable emulsion for foliar fertilizers. | Maximizes nutrient absorption efficiency, reducing waste from uneven application. |

| Duplex Filter System | Removes solid impurities from the liquid solution. | Prevents clogging in fertigation systems (eliminating downtime waste) and ensures product consistency. |

| Automated Control (PLC) | Monitors and controls parameters like temperature, pH, mixing time, and flow. | Ensures quality at the source, reduces human error, and allows for real-time process optimization. |

| Storage & Transfer System | Holds finished product and integrates with fertigation infrastructure. | Creates a smooth, continuous flow from production to application with minimal handling. |

The advantages of a dedicated liquid fertilizer production system for greenhouse cultivation are impactful.

A Lean Liquid Fertilizer Production System for Greenhouse, powered by LANE Heavy Industry’s advanced machinery, is a game-changer for modern greenhouse agriculture. It is an investment in resilience, control, and profitability. LANE’s specialized production line, with its precision, flexibility, and reliability, forms the backbone of an efficient Liquid Fertilizer Production System for Greenhouse, offering growers cost savings, sustainability, and the ability to adapt to changing crop needs. As greenhouse agriculture continues to evolve, the Liquid Fertilizer Production System for Greenhouse will remain a critical tool for maximizing productivity, ensuring food security, and driving the future of sustainable farming.

Q1: What raw materials can be used in an on-site liquid fertilizer production system for a greenhouse?

The system is highly versatile. It can process standard water-soluble mineral salts (e.g., potassium nitrate, calcium nitrate) for precise hydroponic solutions. More innovatively, it can also handle a wide range of organic materials, including fish waste (for fish protein fertilizer), amino acids, humic/fulvic acids, and compost leachates. This allows greenhouses to create powerful, customized organic or blended fertilizers.

Q2: Is the liquid fertilizer produced on-site as effective as commercial products?

Yes, and often it can be superior because it is freshly made and tailored. Peer-reviewed studies have shown that organic liquid fertilizers produced from food waste can achieve equivalent fresh-weight yields in lettuce compared to commercial inorganic fertilizers in both soil and hydroponic greenhouse systems. The key is proper formulation and quality control during production.

Q3: How does a liquid fertilizer production system for a greenhouse integrate with existing irrigation?

The system is designed for seamless integration. The finished liquid fertilizer is typically stored in a central tank that feeds directly into the greenhouse’s fertigation system—the technology that injects fertilizer into the irrigation water. This allows for fully automated, precision feeding of crops through drip or sprinkler systems.

Q4: What technical support is available for operating and maintaining such a system?

Reputable manufacturers like LANE Heavy Industry provide comprehensive support. This includes remote video guidance, detailed operational manuals, and often a five-year warranty on core machinery. Many also offer on-site installation supervision and worker training to ensure smooth start-up and long-term operational success.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Leave a Comment

Latest Posts

LANE has more than 500 successful cases and is committed to providing customers with first-class solutions, high-end machinery and equipment, and one-stop pre-sales, sales and after-sales comprehensive customer service.