Flowing Precision: Inside the 10t Liquid Fertilizer Production System Powering Modern Orchard Nutrition

A 10t liquid fertilizer production system might look like a complex array of pipes and stainless-steel vessels, yet it has quietly become one of the most influential technologies shaping orchard nutrition today. Within the first minutes of observing how modern fertilizer factories operate, the importance of a 10t liquid fertilizer production system becomes vividly clear. As fruit growers demand more consistent, cleaner, and precisely formulated nutrient solutions for drip irrigation and fertigation, the ability to manufacture stable batches of liquid fertilizer has never been more essential. And throughout this entire process, the 10t liquid fertilizer production system serves as the backbone connecting raw agricultural materials with the nutritional needs of fruit trees.

In recent years, orchards have undergone a quiet technological revolution. Traditional granular fertilizer, once dominant, now shares space with liquids designed for rapid uptake and easy integration into irrigation systems. The move toward liquid formulations is driven by a desire for precision—ensuring every tree receives the exact nutrients it needs at the exact time. This shift has placed new pressure on fertilizer manufacturers, who now rely heavily on automated infrastructure like the 10t liquid fertilizer production system to meet these expectations.

Walk into any facility producing specialized orchard fertilizers and you will find that the entire workflow revolves around stability and consistency. The 10t liquid fertilizer production system is engineered exactly for this purpose. It maintains steady production volume, controls temperatures and dissolution rates, and ensures that each component—from nitrogen sources to potassium salts to micronutrient additives—is fully incorporated into the final blend.

This type of production is no longer a luxury; it has become the standard for orchard suppliers worldwide.

The first major section of a 10t liquid fertilizer production system begins with the dissolving equipment. Unlike simple mixing tanks, these tanks are built for controlled heating, agitation, and precise dosing of raw powders. Inside them, soluble forms of nitrogen, phosphorus, potassium, and chelated trace elements gradually dissolve, forming the initial nutrient base.

The mixing tank plays a critical role because fruit-tree fertilizers often include components—such as humic acids or amino-acid complexes—that require specific temperatures and agitation speeds to fully disperse. Rather than listing the tank as an isolated piece of equipment, manufacturers treat it as the first “chapter” of a continuous process. Operators oversee how powders enter the tank, how water circulates, and how sensors track concentration changes. The entire system behaves almost like a giant controlled chemistry laboratory, and this level of control is exactly what the 10t liquid fertilizer production system is known for.

Once the primary solutions leave the dissolving stage, they flow into a second major piece of equipment within the 10t liquid fertilizer production system—the blending reactor. This reactor sits at the heart of the production line, coordinating temperature, flow speed, agitation strength, and ingredient sequencing. It is here that the fertilizer’s personality is created: its texture, clarity, nutrient ratio, and stability.

The blending reactor of a 10t liquid fertilizer production system rarely stops. It may run multiple formulations in a single day—one batch designed for citrus, another for grapes, a third for apples—and yet the system keeps the transitions clean and efficient. Sensors placed around the tank track pH levels, nutrient concentrations, and density to ensure every batch meets orchard requirements.

Inside the reactor, agitators rotate with measured precision, creating a thorough homogenization that orchard farmers depend on. If the nutrient mix is not perfectly uniform, fertigation emitters may clog or deliver uneven doses, affecting the overall crop. This is why the blending reactor is indispensable and why the 10t liquid fertilizer production system handles the process with such reliability.

As the blended fertilizer forms into a clear nutrient solution, the next step highlights one of the most important pieces of equipment in the 10t liquid fertilizer production system—the dual-filter-machine. In orchard fertigation, impurities larger than a grain of sand can cause expensive irrigation failures. For this reason, filtration is not treated as a simple add-on but as a crucial performance guarantee.

The filtration components in a 10t liquid fertilizer production system often include fine-mesh filters, stainless-steel storage tanks, and sometimes multi-stage filtering designed to trap even microscopic particles. During production, operators watch the flow through these filters as carefully as surgeons monitoring vital signs. If the flow shifts, it could indicate incomplete dissolution upstream or excessive viscosity in the blend. Either issue could impact the orchards waiting on the final product.

This filtration stage is what ensures that citrus groves, apple orchards, and vineyard systems can inject liquid fertilizer without worrying about blockages. The smoother the output from the 10t liquid fertilizer production system, the more efficiently the orchard can operate.

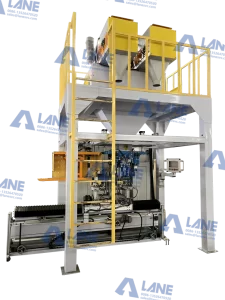

Every drop of fertilizer eventually reaches its destination—usually bottles, drums, or IBC tanks. The final production phase involves another essential piece of equipment: the automated liquid packaging machine. Even though filling appears simple from the outside, in a 10t liquid fertilizer production system it becomes a high-precision operation.

Each container must receive an exact volume to comply with commercial standards. For orchard suppliers, packaging uniformity builds trust; growers want to know that every drum delivers consistent concentration. Automated packaging machines within the 10t liquid fertilizer production system therefore include anti-drip nozzles, flow meters, and weight-checking sensors. They function continuously, linking production output directly to logistics and distribution.

Cleanliness is equally important. Because the same line may switch formulas throughout the day, the filling unit must support rapid cleaning cycles. This is another reason the 10t liquid fertilizer production system has become popular—its layout encourages efficient washing and minimal downtime.

Beyond the tanks and mechanics, the 10t liquid fertilizer production system carries an intelligent layer of automation. PLC systems, touchscreen controls, real-time monitoring, and digital dosing modules work together to maintain accuracy. This digital infrastructure acts as the system’s nervous system, coordinating everything from temperature regulation to flow rates to ingredient sequencing.

For orchard-focused fertilizers—where nutrient precision influences fruit quality—this digital integration is essential. And it is here that manufacturers like LANE demonstrate their advantage.

LANE has earned the position in the fertilizer machinery field by specializing for more than 20 years in the engineering, design, manufacturing, and installation of complete fertilizer production equipment. Our involvement often begins long before a facility installs a 10t liquid fertilizer production system. Customers bring us orchard-specific requirements, expected production schedules, and nutrient formulation plans, and we converts these needs into detailed engineering layouts.

Because we designs and manufactures every major component—from dissolving tanks to reactors to filtration modules—our company can optimize the entire 10t liquid fertilizer production system as a unified whole rather than assembling disconnected pieces. This engineering depth is a major reason growers and fertilizer producers trust our solutions.

Beyond installation, we provides full-scale service: preventative maintenance, on-site troubleshooting, remote diagnostics, and system upgrades. Our equipment meets ISO 9001 and CE standards, ensuring safety and durability. And for manufacturers expanding into NPK, organic fertilizer, or compound fertilizer markets, we provides compatible production lines that integrate naturally with our existing liquid fertilizer infrastructure.

With orchards increasingly relying on fertigation, stable fertilizer quality has become inseparable from crop success. A 10t liquid fertilizer production system ensures that fruit growers receive nutrient blends that are predictable, clean, easy to apply, and tailored to the needs of specific fruit species. The technology saves growers time, reduces labor demands, eliminates inconsistencies, and supports sustainable nutrient management.

As climate change challenges modern agriculture, systems like the 10t liquid fertilizer production system offer the consistency required to maintain yield and fruit quality. Every tank, pump, heat controller, agitator, filtration cartridge, and filling nozzle plays a role in shaping the future of orchard nutrition.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Leave a Comment

LANE has more than 500 successful cases and is committed to providing customers with first-class solutions, high-end machinery and equipment, and one-stop pre-sales, sales and after-sales comprehensive customer service.