Since liquid fertilizer has the advantages of wide raw material sources, high economic value, and simple production process, more and more fertilizer plants have begun to invest in liquid fertilizer production lines to produce liquid water-soluble fertilizers.

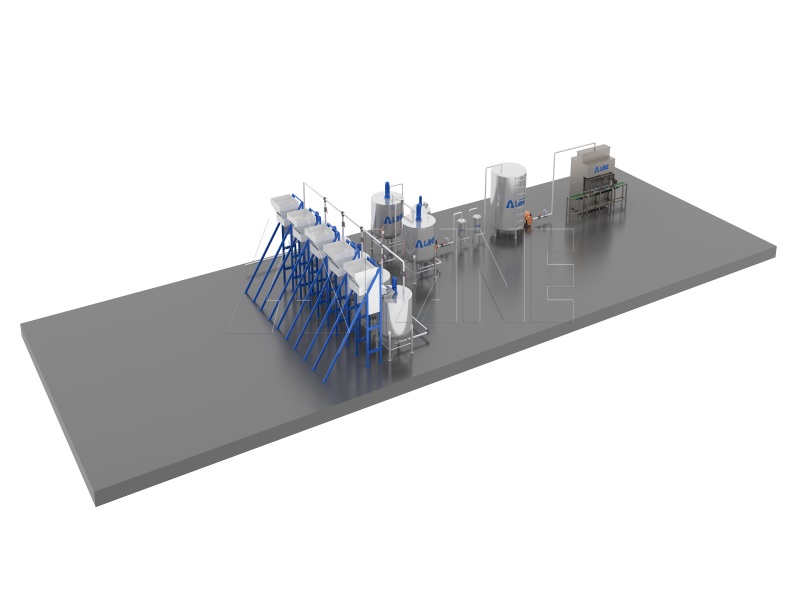

High-humidity material crusher, solid-liquid separator, filter, ultraviolet sterilization, mixing system, fermentation system.

The purity of liquid fertilizer depends on the purity of the raw materials. Therefore, it is very important to process the raw materials before making liquid fertilizer. You can process the raw organic materials in the following ways.

In order to speed up solid-liquid separation, you need to use a crusher to crush bulk materials. LANE produces different types of crushers. We can recommend a suitable crusher according to your raw material type.

2.Solid-liquid separation

Because you are producing liquid fertilizer, you need to collect wastewater from animal manure and agricultural waste. At this time, you need to use a solid-liquid separator. LANE’s screw extrusion solid-liquid separator can dehydrate materials with a water content of about 80% to about 40%.

3.Filtering raw materials

After precipitation, in order to obtain materials with higher purity, the precipitated raw liquid needs to be filtered twice with a filter.

4.Sterilizing materials

Because the raw materials contain harmful bacteria. In order to prevent these harmful bacteria from entering the food chain and endangering human health and plant growth, the raw materials need to be sterilized and disinfected. The liquid fertilizer production lines designed by LANE adopts ultraviolet sterilization and disinfection. In this way, the harmful bacteria in the raw materials can be completely removed.

Processing the liquid fertilizer raw materials through the above five steps can improve the safety of the finished liquid fertilizer and obtain high-purity liquid fertilizer.

After the raw materials are processed, the next two steps are to mix the raw materials evenly and the other is fermentation.

1.Mixed materials

As mentioned above, some functional substances such as synergists should be added to adjust the pH and nutrient content of the raw materials, and fermentation bacteria should be added to promote anaerobic fermentation. When choosing these auxiliary materials, those that are easily soluble in water should be selected. In addition, if the particles of the auxiliary materials are large, they need to be crushed to the extent that they can be dissolved in water with a pulverizer.

2.Fermentation

The prepared liquid is passed into the fermentation tank for pressurized and aerated fermentation under the action of a centrifugal pump. At this step, attention should be paid to the ambient temperature to ensure that the fermentation proceeds normally.For the mixing and fermentation process of liquid fertilizer ingredients, the batching tank and fermentation tank designed by LANE are composed of three layers: inner liner, heat conduction layer, and insulation layer, which can effectively ensure that the liquid fertilizer is fermented at room temperature.

As mentioned above, it is easy to collect raw materials, so what types of raw materials can you collect to make liquid fertilizer?

1.Animal manure

Animal manure contains a large amount of nutrients such as protein and organic matter. It is one of the important raw materials for the production of liquid fertilizer. Animal manure can be used to produce liquid fertilizer with high nutrient content.

2.Methane pool

Methane waves are rich in nutrients. They not only contain organic matter, but also contain humic acid that can improve plant resistance. Therefore, biogas liquid is another important raw material for making liquid fertilizer, and biogas liquid still retains complete nutrients after fermentation under anaerobic conditions.

3.Agricultural waste

A large amount of nutrients are still left in abandoned crops. Agricultural waste can be made into water-soluble fertilizers to turn waste into treasure, and crude protein and crude fat in agricultural waste can be used to promote plant growth.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Leave a Comment

LANE has more than 500 successful cases and is committed to providing customers with first-class solutions, high-end machinery and equipment, and one-stop pre-sales, sales and after-sales comprehensive customer service.