The world is entering the modern age of agriculture. With the incentive given by governments all over the world to sustain an 8 billion population, agribusiness and small to medium scale farmers are looking for fast and efficient agricultural solutions. Liquid fertilizer has emerged as a preferred choice for farmers due to its high nutrient utilization and precise application advantages.

Investors are looking to capitalize on this opportunity. To them, understanding the cost structure of liquid fertilizer production line investment is crucial. It will help them make informed decisions and capitalize on this growing demand and is crucial for planning and ensuring a strong return on investment (ROI). Henan LANE Heavy Industry, a professional manufacturer of fertilizer production equipment with their 20 years of experience, will help you with insights into this investment landscape.

This article will explain the complete cost of a liquid fertilizer production line investment.

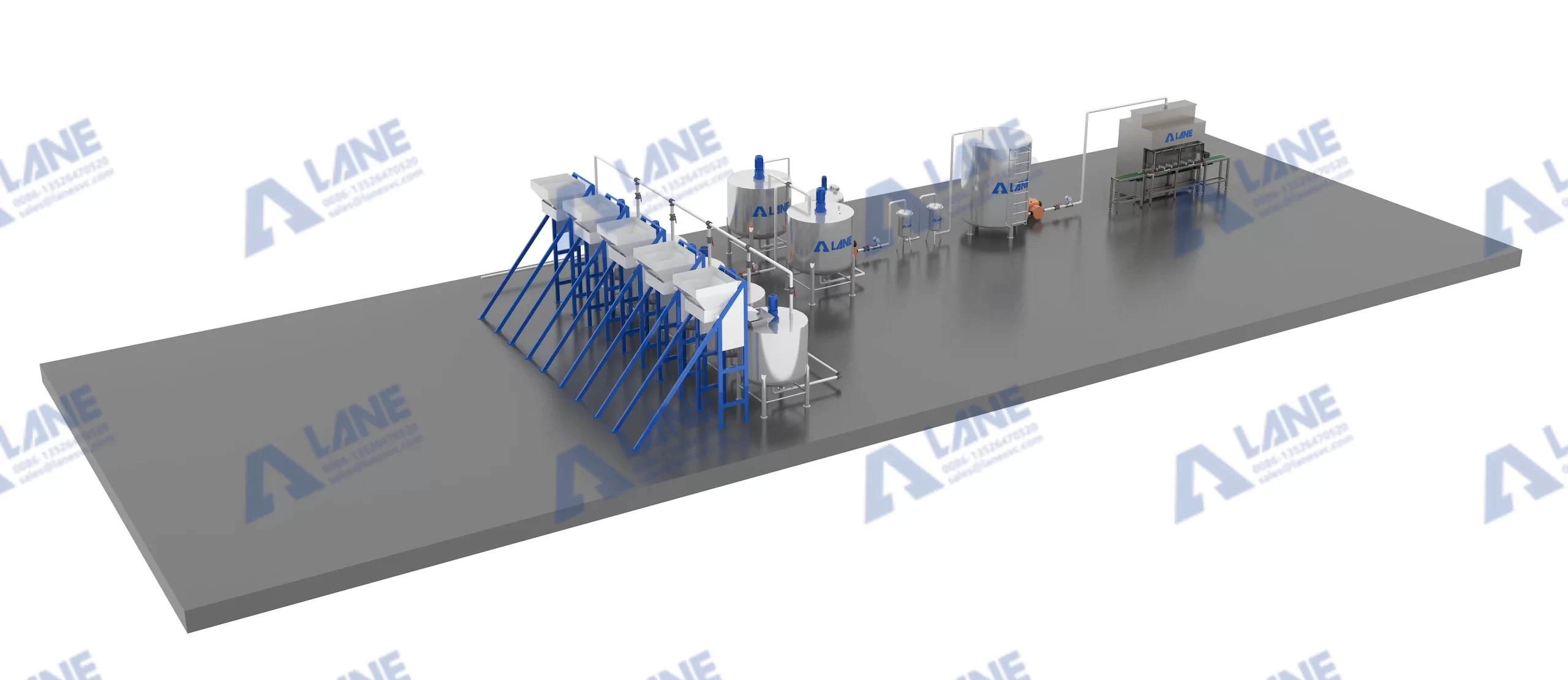

A standard liquid fertilizer production line is a complete system, not a single machine. You have to consider that your investment covers several integrated components, each contributing to the final product’s quality and consistency.

This includes crushers, shredders, and powerful stainless-steel mixing tanks with agitators. Depending on the raw material and type of fertilizer, the machine list changes. The cost of these machines changes depending on the capacity, material grade (e.g., 304 vs. 316 stainless steel), and automation level.

LANE Heavy Industry engineers design this system for homogeneity and efficient raw material utilization. We understand that any small shift in the machine could result in loss for the customer.

Organic or bio-fertilizers need controlled fermentation. This involves insulated, heated tanks with precise aeration and temperature control systems, sometimes with a spray tower for odor control. The cost of this equipment is often among the more significant equipment costs. They are complex machines and big in size.

After fermentation or chemical reaction, the liquid must be filtered. Investment includes filter presses, dual duplex filters, centrifugal separators, or membrane filtration systems. This choice impacts final product clarity, shelf-life, and application method.

Before packing, nutrients and additives must be perfectly homogenized. High shear homogenizers and final storage tanks make sure the final product is stable before packing. Storage capacity directly influences your operational scalability.

LANE Heavy Industry provides fully automatic packing machines that can operate without any human touch. This makes the fertilizer safe from any human errors. This can range from semi-automatic filling stations to fully automated lines with capping, labeling, and palletizing. Cost varies based on required speed (bottles/hour) and packaging formats (bottles, cans, IBC totes).

The brain of the operation is a PLC-based system or computer-based system which can automate processes, ensure repeatability, and reduce labor costs. The whole production line can be managed from a single command center.

Prices vary based on scale, location, and customization.

This is the most substantial portion. A small to medium scale, semi-automatic line from LANE Heavy Industry can start in the range of $50,000 – $150,000. A fully automated, large-capacity line with advanced fermentation and filtration can range from $200,000 to over $500,000. This includes design, manufacturing, and factory testing.

LANE sends technicians for on-site assembly, electrical and plumbing hookups, and initial system calibration. We manage this phase to ensure the line is installed correctly and operators are trained. This prevents costly operational errors.

This cost is often overlooked. These soft costs include:

Factory Modifications: A factory must have reinforced flooring, drainage, ventilation, and possibly climate control.

Utility Hookups: The factory must integrate industrial-grade electrical power (for motors and heaters), water supply and discharge points. Some production lines need steam or gas lines for fertilizer production.

Safety & Compliance: This is a mandatory cost. You must meet local environmental and safety regulations. This includes buying safety equipment, fire or other hazard control systems.

You need to secure funding for purchasing the first few batches of raw materials and packaging. These raw materials might include mineral concentrates, organic bases, and additives.

This is the budget for product testing, quality certifications, and business licensing.

LANE Heavy Industry can provide the most effective way to control costs and maximize value over the lifecycle of your production line.

Customized, Scalable Solutions: LANE Heavy Industry does not believe in one-size-fits-all. We assess your target market, raw materials, and budget to design a production line that meets your current needs with a clear path for future expansion.

Focus on Lifetime Value: Our materials are durable and modular. While the initial liquid fertilizer production line investment might be higher than with low-cost providers, the reduced downtime, lower maintenance costs, and longer equipment life will lead to a lower total cost of ownership.

Turnkey Project Management: LANE acts as a single point of responsibility. We provide design, manufacturing, installation, and training. This removes the headaches of coordination and also removes the hidden cost of dealing with multiple vendors.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Leave a Comment

Latest Posts

LANE has more than 500 successful cases and is committed to providing customers with first-class solutions, high-end machinery and equipment, and one-stop pre-sales, sales and after-sales comprehensive customer service.