Key Considerations for Setting Up a Liquid Fertilizer Production Line in South America

South America’s agricultural growth is driven by the rising demand of high-yield crops. They have many huge soybean, corn, sugarcane, and coffee plantations. This creates ongoing demand for efficient, high-quality fertilizers. Liquid fertilizers are known for their high nutrient absorption rate and compatibility with fertigation systems. It is becoming more popular and creates opportunity for small business to open liquid fertilizer production line in South America.

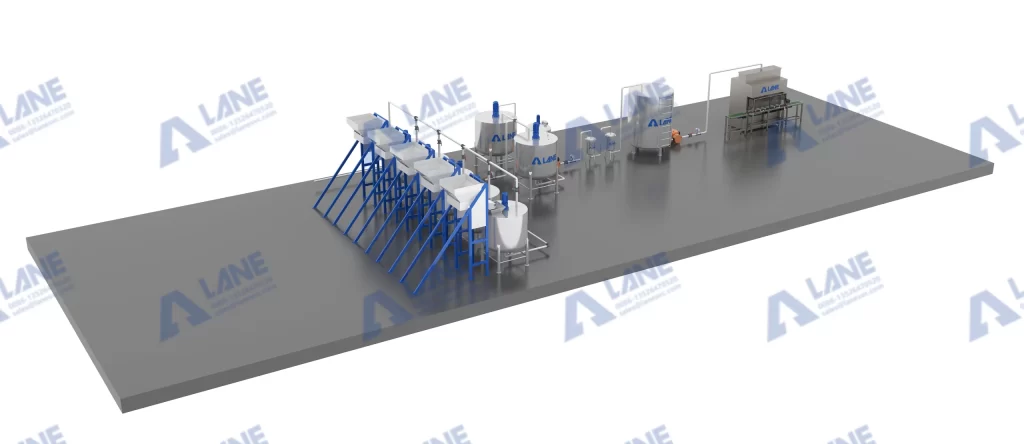

Establishing a liquid fertilizer production line in South America is an opportunity. but setting up a Establishing a liquid fertilizer production line in South America requires knowledge about local market dynamics, regulatory frameworks, raw material availability, and equipment adaptability. LANE Heavy Industry, a leading manufacturer of fertilizer machinery offers Liquid fertilizer production line which us customizable and scalable.

South America is a large continent with different cultures, landscapes, and farming product variations. A one-size-fits-all approach won’t work here. Your liquid fertilizer production line in South America must be adaptable.

Durable machinery will make your production smoother. You must select equipment built for performance and efficiency.

For a successful production line, you must work beyond your factory floor.

When investing in capital-intensive machinery for a demanding production line, the partner you choose is as important as the technology itself. LANE Heavy Industry stands out for the South American market because of our:

Setting up a liquid fertilizer production line in South America requires a strategic approach that integrates market insights, regulatory compliance, raw material adaptation, and reliable machinery. You must carefully consider the region’s unique agricultural profile and partner with a machinery manufacturer that prioritizes durability, customization, and support. You can build a resilient, profitable business at the heart of South America’s agricultural future.

Q1: What is the minimum space and investment required for a basic liquid fertilizer production line from LANE?

A1: Requirements vary significantly based on capacity and automation level. A compact, semi-automatic blending line for local markets can be housed in a 500-800 sqm facility. LANE provides detailed feasibility consultations to outline specific investment and space needs for your business plan.

Q2: Can LANE’s production lines handle both clear liquid and suspension fertilizers?

A2: Absolutely. Our engineering is tailored to the product. We configure lines with the appropriate mixers, agitators, and homogenizers to produce stable clear solutions, Suspended Liquid Fertilizers (SLF), and denser fluid mixes without settling.

Q3: How does LANE address the challenge of corrosive raw materials?

A3: Corrosion resistance is a core design principle. We use high-grade stainless steel (SS304, SS316L), apply specialized protective linings, and incorporate composite materials in key components to ensure the longevity and safety of the entire liquid fertilizer production line.

Q4: Do you provide assistance with regulatory compliance for different South American countries?

A4: While local regulatory approval is always the client’s responsibility, LANE provides extensive documentation, equipment certifications, and facility layout designs that meet international industrial safety and quality standards. This documentation is crucial for streamlining the local approval process in any South American country.

Q5: What kind of after-sales support can I expect in South America?

A5: LANE offers comprehensive support, including remote technical assistance, detailed operation manuals, on-demand operator training (on-site or at our facilities), and a reliable supply chain for critical spare parts to ensure your production runs smoothly.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Leave a Comment

Latest Posts

LANE has more than 500 successful cases and is committed to providing customers with first-class solutions, high-end machinery and equipment, and one-stop pre-sales, sales and after-sales comprehensive customer service.