Business Models for a Profitable Liquid Fertilizer Production Line in Canada

In Canada, agriculture is the cornerstone of the economy and fertilizers play a critical role in enhancing crop production. Vast farmlands dedicated to wheat, canola, corn, and horticultural crops create a demand for precision liquid fertilizer. Modern farmers are seeking efficient, targeted solutions that integrate seamlessly with fertigation and foliar application systems.

Investing in a modern liquid fertilizer production line in Canada represents a significant opportunity to meet this demand locally. The market for liquid fertilizer is steadily growing, and North America is a key region in this expansion. By establishing a production facility, entrepreneurs and agricultural cooperatives can tap into a market that values quality, consistency, and tailored nutrient solutions for diverse crops.

This article will explore how machinery from LANE Heavy Industry can form the foundation of several profitable business models for a successful liquid fertilizer production line in Canada.

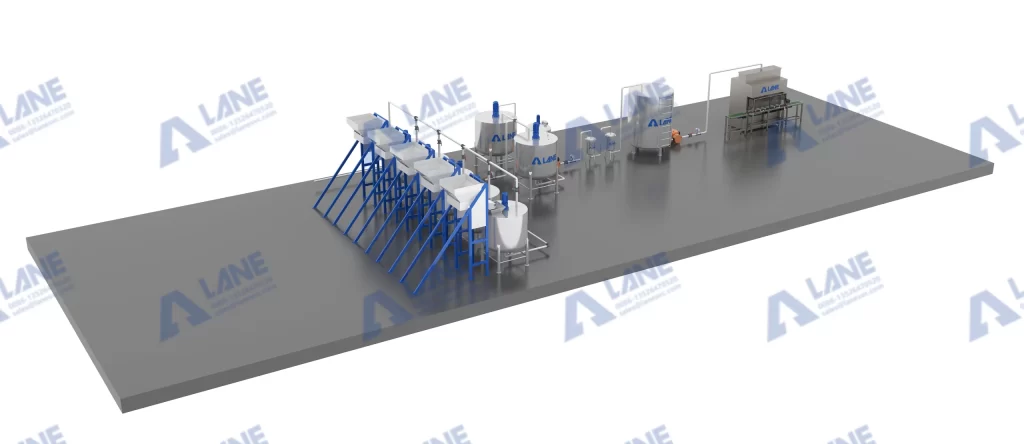

A successful business venture requires the right business model, planning, and the right equipment. LANE Heavy Industry Machinery Technology Co., Ltd. provides customized solutions for setting up a liquid fertilizer production line in Canada. Our liquid fertilizer production line is designed to handle everything from raw material intake and mixing to final packaging.

A standard LANE liquid fertilizer production line includes stages for raw material preparation, high-shear mixing for emulsification, filtration, and automated packaging. The equipment is built with core industrial components like PLCs, pressure vessels, pumps, and stainless-steel mixing and fermentation tanks. This ensures durability and consistent output. Key advantages for a Canadian business include:

Here are four viable business models tailored for the Canadian market, centered around a versatile liquid fertilizer production line in Canada.

| Business Model | Target Customer | Key Value Proposition | Raw Material Focus |

| Contract Manufacturing & Private Label | Large agri-retailers, input distributors, co-ops | Low-risk market entry for brands; consistent, high-volume production. | Standard NPK blends, custom formulations. |

| Specialty & Organic Fertilizer Production | Organic farms, vineyards, horticulture, greenhouses | Premium, sustainable products; compliance with organic standards. | Fish hydrolysate, humic/fulvic acid, kelp, plant-based compost. |

| Regional Custom Blending Service | Local grain, corn, and specialty crop farmers | Hyper-localized agronomy; just-in-time blending for soil/season. | Blends based on regional soil tests and crop needs. |

| Waste-to-Value Circular Solution | Food processors, breweries, livestock operations | Waste management fee + product revenue; sustainability story. | Food waste, soybean dregs, manure, other agri-waste. |

Launching a liquid fertilizer production line in Canada requires careful planning. Here is a phased approach:

Your first step should always be conducting a detailed market analysis for your chosen fertilizer. Engage with potential customers like farmers, retailers, or waste producers to validate demand. Discuss with LANE about capacity, layout, and customization needs based on your raw materials and product goals.

Secure your business structure, location, and necessary permits. Finalize the equipment order and ensure that specifications meet Canadian standards. This period includes factory acceptance tests and logistic arrangements for the liquid fertilizer production line in Canada.

LANE engineers oversee the installation, connect all components like crushers, reactors, mixing tanks, and filling lines, and conduct rigorous testing. In this stage, LANE will teach your team about the production and give them training.

This is the last stage. In this stage, you do a trial run of your production line. Obtain product certifications and initiate your sales and marketing campaign. Start with pilot customers to refine your product before full-scale commercialization.

Q: What is the typical cost and lead time for setting up a LANE production line?

A: Cost varies significantly based on capacity, automation level, and customization. As a reference, individual machines can be produced in about 7 days, while a complete customized liquid fertilizer production line may take up to 30 days for manufacturing, plus shipping and installation time. Direct consultation with the supplier for a quote is essential.

Q: I have no technical background. Can I still operate this business?

A: Yes. Reputable suppliers like LANE provide comprehensive support. This includes detailed process design, on-site installation and commissioning by their engineers, and thorough training for your operators to ensure they can run and perform basic maintenance on the equipment independently.

Q: Can one production line make different types of liquid fertilizer?

A: Absolutely. A well-designed line is versatile. By changing raw materials and adjusting formulas, you can produce a wide range of products, from clear nutrient solutions to emulsified foliar feeds and organic-based fertilizers. This flexibility allows you to adapt to market demands.

Q: How do I handle raw material sourcing in Canada?

A: Your business model dictates sourcing. For chemical-based lines, you will procure soluble salts from distributors. For organic or waste-based models, you establish partnerships with local food processors, fisheries, or farms. The case of using soybean dregs demonstrates the potential of turning local by-products into valuable inputs.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Leave a Comment

Latest Posts

LANE has more than 500 successful cases and is committed to providing customers with first-class solutions, high-end machinery and equipment, and one-stop pre-sales, sales and after-sales comprehensive customer service.