Operating a Liquid Fertilizer Production Line in Belarus: A Complete Guide | LANE Heavy Industry

Table of Contents

Belarus, known for its fertile agricultural lands and strategic position in Eastern Europe, presents a compelling opportunity for investment in agro-industrial production. It is an ideal market for agriculture-related businesses. As demand for efficient, eco-friendly fertilizers grows among local farmers and agricultural enterprises, establishing a liquid fertilizer production line in Belarus will allow entrepreneurs to tap into a stable domestic market and growing export channels to neighboring countries. However, success requires careful planning, adherence to local regulations, high-quality equipment, and strategic management.

This article outlines the key requirements for operating a liquid fertilizer production line in Belarus with the help of LANE Heavy Industry’s advanced machinery. LANE Heavy Industry is an industry leader trusted for its machines’ reliability and performance in liquid fertilizer production lines globally.

Before installing any equipment, secure the proper legal paperwork. This involves registering your business entity with Belarusian authorities, which can be streamlined through the country’s investment promotion agencies. After that, you must obtain the necessary environmental and industrial permits for liquid chemical fertilizer production. Engage with a local legal consultant or firm experienced with agro-chemical regulations. Making a clear business plan that accounts for these setup costs and timelines is the first critical step toward launching your liquid fertilizer production line in Belarus.

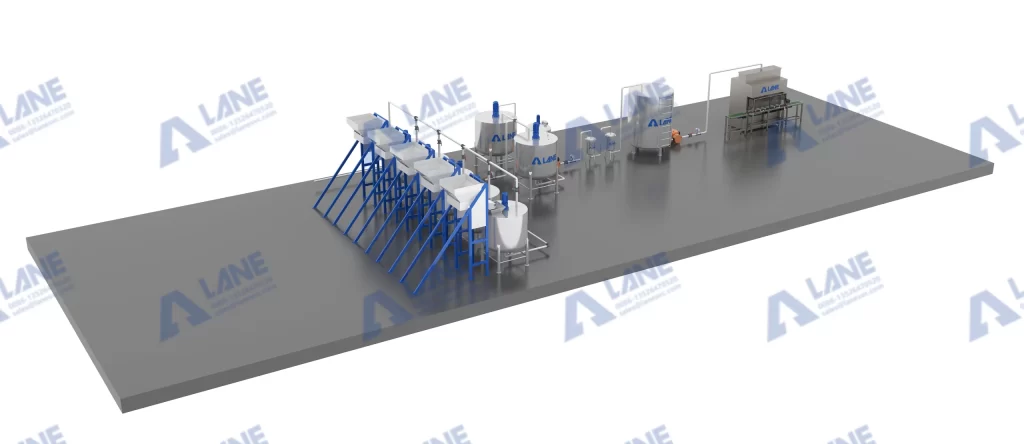

The core of your venture is the liquid fertilizer production line. The liquid fertilizer production line is not a single machine but a whole setup. For a reliable and efficient setup, many operators choose proven manufacturers like LANE Heavy Industry. A standard line for producing suspensions or NPK solutions typically includes:

LANE Heavy Industry offers customized engineering and designs along with after-sales support. We ensure that your liquid fertilizer production line in Belarus is tailored to your specific product formulations and scale. This minimizes downtime and technical risks.

Belarus is home to major producers of nitrogen and potash fertilizers. This provides a significant logistical advantage. Sourcing key raw materials like potassium chloride locally drastically reduces costs and supply chain complexity. Building strong relationships with local and regional suppliers is key to securing stable, cost-effective raw material flows for your liquid fertilizer production line.

A sophisticated production line requires skilled personnel. You will need a team that includes a production chemist (to oversee formulations and quality), maintenance engineers, and machine operators. Investing in thorough training is non-negotiable. LANE Heavy Industry offers comprehensive operator training to ensure your team can efficiently and safely manage the entire liquid fertilizer production line in Belarus.

Consistent quality is your brand’s reputation. An on-site laboratory is necessary to test raw material purity, solution pH, nutrient concentration (NPK ratio), and stability. Your liquid fertilizer must comply with Belarusian State Standards and, for export, the regulations of target markets (like the EU’s CE marking or Eurasian Economic Union technical regulations). Implementing a QC protocol from day one is essential for any liquid fertilizer production line in Belarus to build trust with commercial farms and distributors.

You should construct your factory in an optimal location. It should have proximity to raw material sources, railways, or major highways for distribution. Belarus has a well-developed rail network ideal for bulk transport. You’ll need to establish a distribution model: Will you sell directly to large agricultural holdings, supply regional agro-dealers, or focus on private label production? Understanding the local sales channels and using them to build a competent sales and logistics team is the final step for your liquid fertilizer production line in Belarus.

Operating a liquid fertilizer production line in Belarus is a viable and profitable venture, but it requires careful attention to legal compliance, equipment selection, raw material quality, staff training, and maintenance. It combines industrial manufacturing with deep agricultural insight. By choosing LANE Heavy Industry’s advanced machinery, you get customizable, efficient, and compliant equipment that will help you realize your liquid fertilizer production dream. Whether you are a new investor or expanding your operations, following these guidelines will help you navigate the challenges and achieve success with your liquid fertilizer production line in Belarus.

Q1: What is the approximate investment range for setting up a liquid fertilizer production line in Belarus?

A1: The investment can vary widely based on scale and automation level. A small to medium-capacity liquid fertilizer production line in Belarus using reliable machinery like that from LANE Heavy Industry can range from several hundred thousand to over a million euros, including setup, commissioning, and initial raw material inventory.

Q2: How long does it take from ordering equipment to starting production?

A2: From contract signing with a machinery supplier to the commissioning of your liquid fertilizer production line in Belarus, typically expect a 6 to 12-month timeline. This includes manufacturing, delivery, installation, building preparation, and staff training.

Q3: Does the Belarusian government offer support for such agro-industrial projects?

A3: Yes, the government often supports import-substituting and export-oriented production. Benefits can include tax holidays, customs duty exemptions on imported equipment, and simplified administrative procedures, especially within designated free economic zones.

Q4: Can LANE Heavy Industry machinery produce both clear solutions and suspension fertilizers?

A4: Yes, equipment lines from manufacturers like LANE Heavy Industry are often designed to be versatile. With the correct configuration of reactors, mixers, and homogenizers, a single liquid fertilizer production line can be adapted to manufacture various products, including clear NPK solutions and more complex suspension fertilizers.

Q5: What after-sales support is crucial for a production line in Belarus?

A5: Given the technical nature of the equipment, reliable after-sales support is vital. This should include readily available spare parts, access to technical documentation, and the availability of remote or on-site service engineers to minimize operational downtime for your liquid fertilizer production line in Belarus.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Leave a Comment

LANE has more than 500 successful cases and is committed to providing customers with first-class solutions, high-end machinery and equipment, and one-stop pre-sales, sales and after-sales comprehensive customer service.