Key Equipment and Investment Costs for a Liquid Fertilizer Production Line for Fruit Trees

Every health-conscious person loves fruits. Fruits are delicious and people love to eat fruit juices. With the increasing demand for high-quality fruits, investing in a dedicated liquid fertilizer production line for fruit trees has become a profitable move. This is why “Liquid fertilizer production line for fruit trees” has become a core asset for modern orchard operators and fertilizer manufacturers.

Unlike generic fertilizers, formulas for fruit trees require precise nutrient balancing. It needs higher potassium for fruit development. It also needs specific micronutrients like boron and zinc, and optimal pH levels. So, building a Liquid fertilizer production line for fruit trees requires careful planning around core equipment and understanding the associated investment. LANE Heavy Industry, a pioneer in the fertilizer machinery industry, offers tailored solutions that balance efficiency, quality and cost-effectiveness. This means setting up a profitable and effective operation is more accessible than ever.

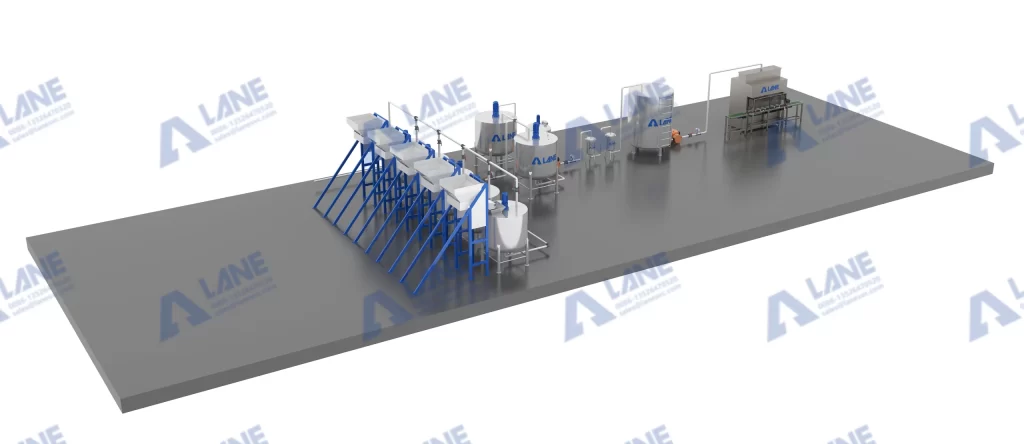

A complete and efficient liquid fertilizer production line for fruit trees created by LANE is a synchronized system. Each piece of equipment plays a role specifically designed for it.

Raw Material Reception & Pre-processing System: This is the starting point. Here, raw materials are stored and crushed if necessary. The raw material pretreatment system includes corrosion-resistant stainless-steel crushers and screw conveyors, which efficiently crush solid raw materials such as potassium nitrate and humic acid into fine particles, ensuring full dissolution. Equipment includes receiving hoppers, conveyors and crushers.

Raw Material Mixing Tank: This is the first mixing tank. LANE’s variable-frequency stirring tank is used in this stage to mix the raw material with purified water or liquids to dissolve the raw material into liquid solutions ready for the main mixing tank. Temperature can be controlled in this tank for precise dissolution. High-shear mixers are essential to create a homogeneous solution.

Main Mixing Tank: In the main mixing tank, different batches of raw materials are sent here to be mixed together to create the formulated solution. The stirring tanks realize precise proportioning of nitrogen, phosphorus, potassium and trace elements through PLC control.

LANE Machinery often equips these tanks with advanced aeration systems and precise thermal controls to ensure complete solution formulation.

Additive Mixing Tank: The raw materials are sent to the additive mixing tank. Here, the liquid fertilizers are mixed with additional additives to increase the shelf life of the fertilizers. It does chelation reactions at constant temperature, which improves fertilizer stability.

Filtration and Clarification System: To ensure a clear, particle-free solution that won’t clog irrigation or foliar spray systems, a durable and effective filtration system is necessary. LANE provides a dual stage filtration system that can precisely filter your liquid solution and make it look premium.

Stabilization Tank: After filtration, the liquid solutions are sent to a storage tank. In this stage, liquid fertilizer is too active to be used on farms. It needs to be stabilized. The storage tank is equipped with a stirring system which prevents the liquid from forming crystals.

Automated Dosing and Filling Line: This is a stage defined by its precision and efficiency. Here, the finished liquid fertilizer is filled into bottles, jerry cans, or IBC totes. LANE Machinery integrates volumetric or weight-based fillers, cappers, and labelers into a single conveyor line, ensuring speed, accuracy, and minimal waste.

PLC Control System & Software: Every LANE liquid fertilizer production line for fruit trees is equipped with a centralized Programmable Logic Controller (PLC). This system automates the whole process. It can control the temperature in the reactors, mixing speed, pH levels, and filling volumes. This makes sure that every batch consists of the same amount of consistency.

The investment for a liquid fertilizer production line for fruit trees varies based on capacity, automation level, and raw material sourcing.

Small-Scale/Batch Line (1-2 tons per day): This is ideal for small farmers or small businesses who want to create their own solution or get their foot in the market to test the viability. Estimated Investment: $50,000 – $150,000. This covers basic tanks, a mixer, a manual filling station, and essential controls.

Medium-Scale/Semi-Automatic Line (5-10 tons per day): This is the most common choice for medium scale businesses. This includes a full mixing system, automated mixing and reaction kettles, a homogenizer, and a semi-auto filling line. Estimated Investment: $150,000 – $400,000. This is a scalable production line with strong automation.

Large-Scale/Fully Automatic Line (20+ tons per day): This production line is made for major manufacturers. This is a completely integrated, closed system, from raw material intake to palletized finished goods, featuring full PLC control, inline quality monitoring (pH, density), and high-speed packaging. Estimated Investment: $400,000 – $1,000,000+ (depending on the capacity).

Material of Construction: This is the main cost factor. Food-grade corrosive resistance stainless steel (SS304 or SS316) is essential for corrosion resistance and product purity.

Automation Level: This is a one-time expense that saves you labor cost and removes human error from production. This improves the consistency of your product.

Auxiliary Systems: Auxiliary systems like steam boilers, water treatment and electrical infrastructure also increase the cost of the production.

Choosing LANE Machinery’s “Liquid fertilizer production line for fruit trees” means gaining professional technical support and product consistency guarantees. We offer tailored solutions, preventing over- or under-investment in equipment.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Leave a Comment

LANE has more than 500 successful cases and is committed to providing customers with first-class solutions, high-end machinery and equipment, and one-stop pre-sales, sales and after-sales comprehensive customer service.