Liquid Fertilizer Production Lines in Australia: Market Outlook and LANE’s Advantages

Australia’s fertilizer sector is shifting: growers want smarter, higher-value inputs (including foliar and fertigation liquid products), regulators expect strict labeling and biosecurity, and market growth is steady. For manufacturers or suppliers of liquid fertilizer production lines, opportunities exist in local manufacturing, turnkey plant supply, and service-driven sales (installation, validation, training). To succeed, suppliers must pair robust stainless-steel production systems, tight QC and formulation controls, and local compliance support. LANE’s modular, automated liquid fertilizer lines — built for hygiene, consistent mixing, filtration, and automated filling — match the operational and regulatory needs of Australian customers.

Multiple market reports indicate the Australian fertilizer market is sizeable and growing gradually; liquid fertilizers represent a meaningful and expanding segment due to precision agriculture and foliar/fertigation adoption. Estimates vary by source, but recent analyses put the broader Australian fertilizer market in the low-to-multi-billion AUD range with single-digit CAGR, while liquid fertilizer value and volume have been increasing as growers adopt targeted application methods to improve nutrient use efficiency.

Key demand drivers for liquid fertilizers in Australia today:

Precision farming: fertigation and targeted foliar spraying raise demand for soluble, stable liquid formulations.

Specialty crops and horticulture: high-value orchards, vineyards and vegetable systems prefer custom liquid blends.

Environmental & cost pressure: growers seek to reduce total nutrient use and runoff while retaining yields — liquid inputs enable more precise application. Recent local industry coverage also notes investments by biological fertilizer firms and R&D spending on biologicals, highlighting a shift toward proprietary liquid bio-inputs.

Australia’s regulatory framework for fertilizers and agvet-type products is strict and multifaceted:

Import & registration rules: Agricultural chemical-type inputs, biologicals, or products claiming “plant growth” or “bioactive” effects may fall under APVMA oversight or require specific permits for importation/registration. Only registered products or approved active constituents can often be imported without extra approvals. This affects both finished products and certain raw inputs.

Biosecurity & import conditions: The Department of Agriculture/BICON system enforces biosecurity import conditions. Raw organic inputs, biological additives, or seaweed/biomass concentrates may need import permits and quarantine/inspection to ensure no pests or pathogens are introduced.

Labeling and composition rules: Australia expects clear nutrient declarations, contaminant limits (heavy metals, toxins), and consistent product descriptions in line with national codes and state requirements. Fertilizer industry guidance bodies provide practical resources to help importers and manufacturers meet label and safety standards.

Implication: Any liquid fertilizer line intended for the Australian market must be paired with product registration support (if applicable), robust QC testing, and documentation protocols to prove stability, impurity levels, and composition. Manufacturing or blending locally — or working with local partners — often simplifies compliance and speeds time-to-market.

a) Local manufacturing vs. import of finished product

Local production (manufacturing/blending in Australia): Attractive when formulas include regionally regulated bioactives, when customers require fast delivery and seasonal responsiveness, or when transportation cost/packaging volumes make imports inefficient. Local production supports “Made in Australia” branding and avoids some import permit issues, but requires capital, compliance testing, and distribution network investments.

Import + local filling: Import concentrated inputs (where permitted) and use local turnkey liquid fertilizer lines for dilution, blending, QC, and filling. This hybrid model reduces capital while retaining compliance control.

b) Customer segments with immediate need

Horticulture & vineyards — demand small-batch specialty blends and rapid delivery.

Large irrigated cropping zones — need high-volume fertigation-ready products.

Organic/biofertilizer brands — require sterile, low-contamination production lines capable of handling biological additives with mild processing to retain activity.

c) Logistics & seasonality

Production planning must reflect seasonal demand spikes (planting, vegetative growth) and storage constraints: liquids occupy large volumes and require suitable tank storage and handling logistics. Contract manufacturing or local warehousing can reduce capital lockup and allow supply flexibility.

To be commercially viable in Australia, a production line should include (in integrated fashion) the following capabilities — framed here as functional requirements rather than dry equipment lists:

Accurate dosing & dissolution: Precise metering for concentrated inputs, salt-handling capability, and effective dissolution to prevent undissolved solids.

Controlled mixing & homogenization: Gentle but thorough mixing to protect bioactives (for biological fertilizers) while achieving stable dispersions for mineral liquids.

Multi-stage filtration & polish: Fine filtration to eliminate particulates that would clog sprayers or fertigation nozzles; redundant/continuous filtration reduces downtime.

Sanitary design & clean-in-place (CIP): Food-grade / chemical-grade stainless steel surfaces, easy CIP systems to prevent microbial growth in storage and pipelines.

Automated filling & batching: PLC control, batch traceability, scalable filling machines for drums, IBCs or small bottles.

QC instrumentation & documentation: In-line sensors (pH, TDS, viscosity), sampling ports, and digital batch records for compliance and repeatability.

These functional capabilities align with Australian compliance expectations (stability, labeling, impurity control) and with growers’ operational needs (sprayer compatibility, fertigation friendliness).

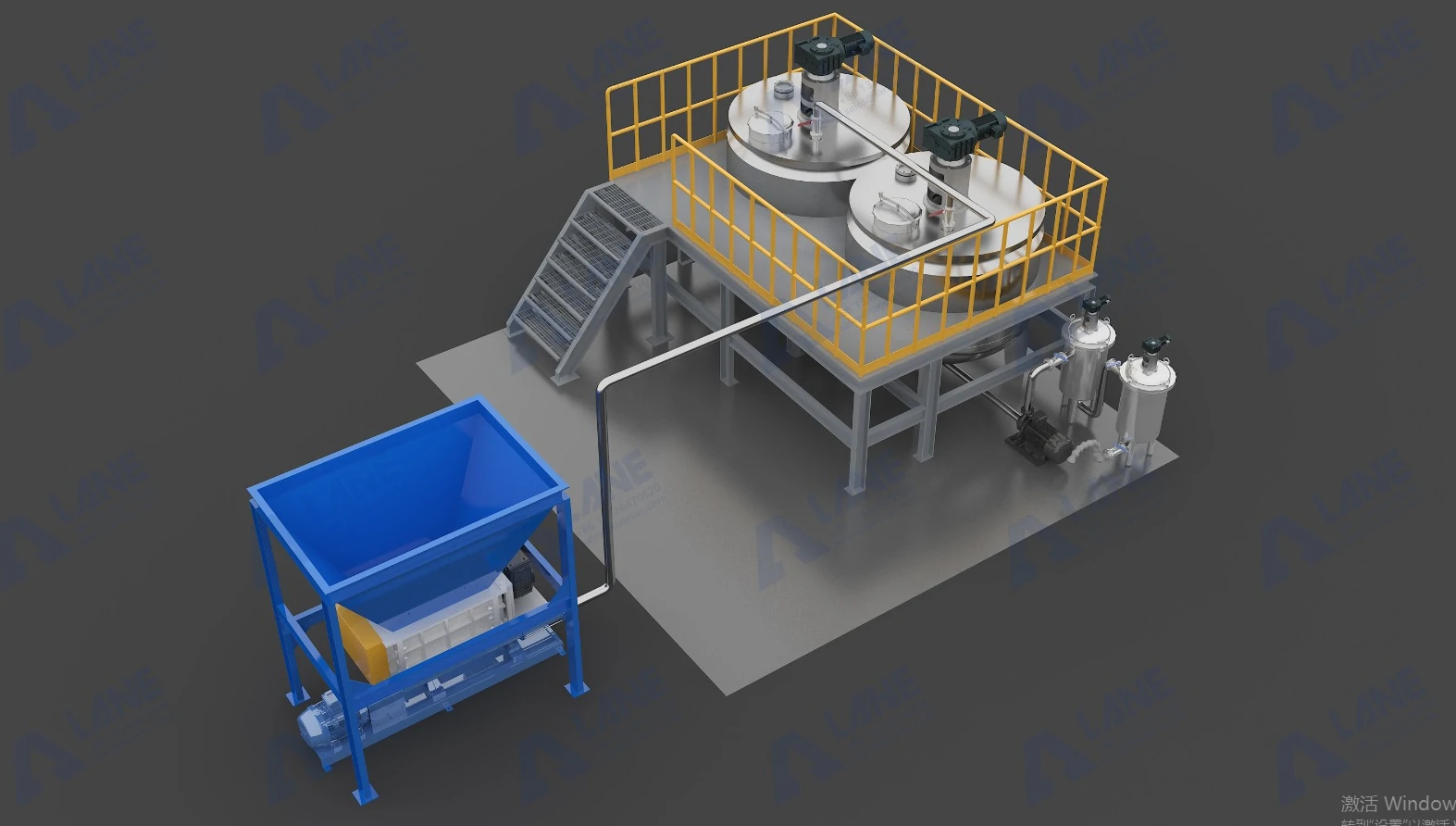

LANE Heavy Industry specializes in complete liquid fertilizer production solutions, providing high-quality, corrosion-resistant, and energy-efficient equipment ideal for Australia’s demanding agricultural conditions. Our systems are designed for both organic and inorganic fertilizer production, with robust engineering to handle continuous operation and variable raw materials.

Key equipment used in LANE’s liquid fertilizer production line includes:

Stainless Steel Mixing Tanks – ensure uniform blending of liquid nutrients with anti-corrosion properties suitable for acidic or alkaline materials.

Automatic Dosing Systems – precisely control nutrient ratios, ensuring consistency and efficiency.

Heating and Stirring Reactors – used for chemical reactions and homogenization of complex formulas.

Filtration Units and Cooling Systems – guarantee purity and product stability before storage.

Filling and Packaging Machines – customizable for bottles, barrels, or bulk containers, ideal for both domestic and export use.

LANE’s systems can be scaled according to production needs — from small pilot-scale setups for agri-tech startups to large industrial plants for regional fertilizer suppliers. All lines are designed for easy maintenance, automation compatibility, and long service life under harsh working environments.

A recent installation of LANE’s liquid fertilizer line in coastal Queensland has shown how efficient local production can be. Using seaweed extract, fish emulsion, and amino acid solutions, the facility produces multiple liquid fertilizer formulations for sugarcane and fruit growers. The plant’s fully automated system improved productivity by 35%, reduced manual labor needs, and ensured consistent product quality — even under humid coastal conditions.

Australia presents a pragmatic and promising market for liquid fertilizer production lines — steady growth, strong demand in precision and specialty agriculture, and a regulatory environment that rewards high-quality, compliant production. Success demands more than selling equipment: it requires partnering on compliance, QC, and after-sales support. LANE’s modular, automated, sanitary liquid fertilizer systems — combined with commissioning and training services — are well positioned to meet Australian manufacturers’ and growers’ needs, whether for small-scale contract filling or full industrial production.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Leave a Comment

LANE has more than 500 successful cases and is committed to providing customers with first-class solutions, high-end machinery and equipment, and one-stop pre-sales, sales and after-sales comprehensive customer service.