Liquid Fertilizer Plant for Agriculture: Modern Solutions for Sustainable Growth

Investing in a liquid fertilizer plant for agriculture isn’t just a technical upgrade—it’s a strategic leap forward. Liquid fertilizers can deliver nutrients more quickly, achieve precise fertilization, and possess flexibility that solid fertilizers cannot match. Whether you produce organic compound fertilizers, NPK solutions, or biological stimulants, establishing the right factory can transform your waste into assets that promote the development of your farm.

Liquid fertilizers dissolve completely, enabling plants to absorb nutrients directly through roots or foliage. Especially in drip irrigation and greenhouse systems, these liquids offer unmatched efficiency, minimizing runoff and maximizing crop uptake. As agriculture moves toward smarter, more sustainable solutions, the liquid fertilizer plant for agriculture model stands out—optimized for speed, control, and adaptability.

Last season, a friend running an indoor hydroponic farm told me they were losing yield due to inconsistent nutrient mixes. After installing a compact liquid fertilizer plant for agriculture to produce tailored blends, yields rebounded by 25%, and nutrient dosing stabilized—no more guessing, just results.

Industry cooperatives are also adopting these plants. One mid-sized rice cooperative we worked with transitioned from bagged NPK to in-house liquid blends. They reduced purchasing costs and improved grain quality—all thanks to better control over nutrient profiles.

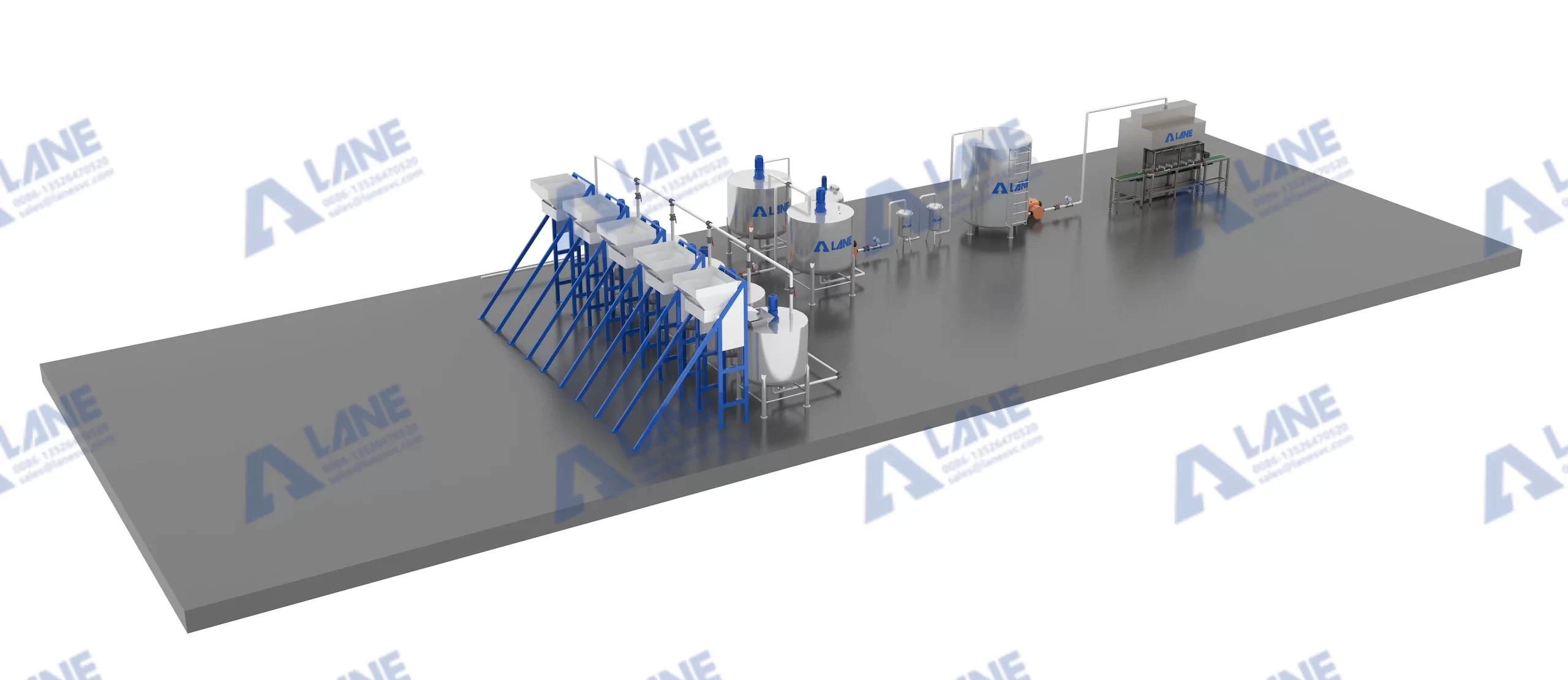

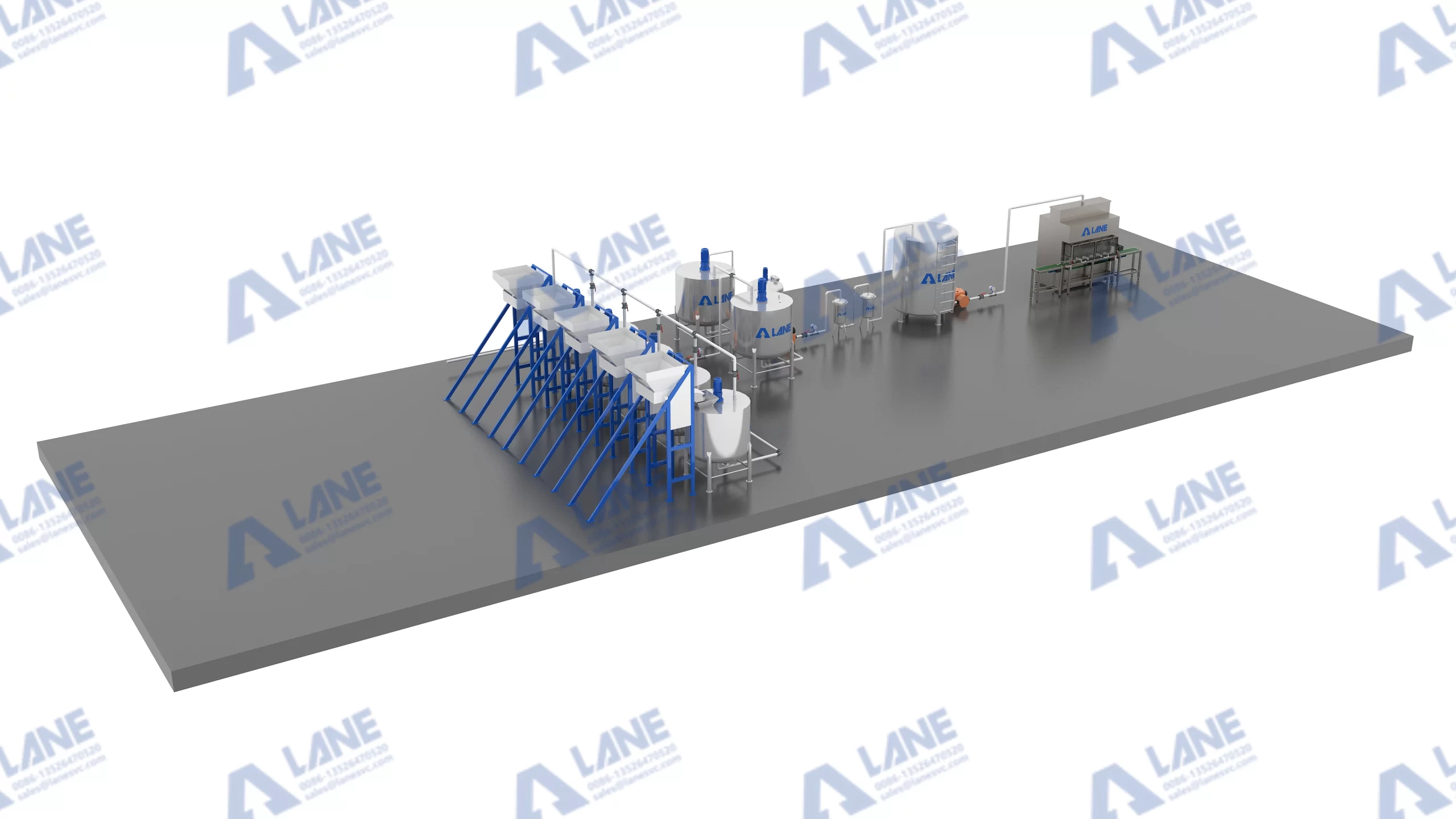

A well-designed liquid fertilizer plant for agriculture integrates efficiency, automation, and quality control at every stage. The following core components form the backbone of a streamlined production line, as adopted by LANE and optimized for both small and large-scale manufacturing.

1.Raw Material Feeding & Initial Mixing

The process begins with raw materials—such as urea, potassium nitrate, and microelements—being fed into the feeding hopper, where they are accurately dosed and conveyed into the raw material mixing tank. This step ensures that all primary nutrients are evenly dissolved in water, forming a consistent base solution ready for further enhancement.

2.Precision Blending in Mixing and Additive Tanks

Once the base is prepared, the solution moves into a main mixing tank, where it’s further blended to achieve the correct concentration. At this stage, additional components—such as stabilizers, chelating agents, pH regulators, or biological enhancers—are introduced via a dedicated additive mixing tank. The dual-tank configuration allows for flexible formulations and faster batch changeovers, ensuring high responsiveness to different crop and seasonal needs.

3.Filtration & Purity Control

To ensure smooth application in drip or foliar systems, the solution passes through a duplex filtration system. These filters eliminate any residual particles or impurities that might clog spray nozzles or irrigation lines, ensuring a clean, high-quality product suitable for direct agricultural use or export.

4.Storage and Packaging

After filtration, the liquid fertilizer is stored in stainless steel storage tanks equipped with temperature control and agitation systems to prevent sedimentation. From there, the product is directed to the automatic filling machine, which handles various container sizes with precision, from small retail bottles to bulk industrial drums.

5.Final Output: Ready-for-Use Fertilizer

The final stage is the finished product—a stable, nutrient-rich liquid fertilizer ready for distribution. Thanks to LANE’s modular and automated design, each batch maintains consistency, traceability, and compliance with global standards.

| Feature | Benefits |

| Fast Nutrient Uptake | Immediate absorption reduces waste and increases yield |

| Precision Dosing | Flexibility for crop-specific or stage-specific nutrients |

| Efficient Application | Ideal for drip & foliar systems—crop-ready dosing |

| Space-Saving Plant Layout | Compact design vs. large granule-blending operations |

| Strong Export Potential | Clean, stable liquids with standardized labels |

In Eastern Europe, a regional farming cooperative sought to reduce dependency on third-party suppliers and gain control over fertilizer quality. With rising demand for efficient and targeted crop nutrition, they partnered with LANE to establish a dedicated liquid fertilizer plant for agriculture.

LANE provided a custom-engineered system capable of producing 20,000 liters/day, equipped with:

Flexible NPK formulation mixing tanks

Duplex filtration for clog-free fertigation

Dual-mode filling machines for both local and export packaging

Within a few months, the cooperative began supplying its own network and exporting to nearby markets, significantly reducing costs and increasing profit margins.

“LANE’s solution changed everything. We now produce and export our own liquid fertilizer with full confidence.”

— Manager, AgroVita Cooperative

This project proves that investing in a liquid fertilizer plant for agriculture can deliver not just better yields, but also long-term economic resilience for rural producers.

A well-designed liquid fertilizer plant for agriculture offers growth, control, and ecological benefits that traditional methods can’t. With LANE’s proven technology and global service network, moving to liquid formulations can be seamless, scalable, and game-changing—whether you’re growing local crops or serving global markets.

Use technology. Stay precise. Grow with confidence.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Leave a Comment

LANE has more than 500 successful cases and is committed to providing customers with first-class solutions, high-end machinery and equipment, and one-stop pre-sales, sales and after-sales comprehensive customer service.