Liquid Fertilizer Manufacturing Equipment and the Future of Crop Nutrition

Liquid fertilizer manufacturing equipment is revolutionizing the way agriculture handles plant nutrition. In the past, solid granular fertilizers dominated global agriculture, but nowadays liquid fertilizer formulations are increasingly favored. The reasons are obvious: Liquid fertilizers can be applied through irrigation and foliar spraying, can be quickly absorbed by crops, and can be customized according to the nutritional needs of the crops.

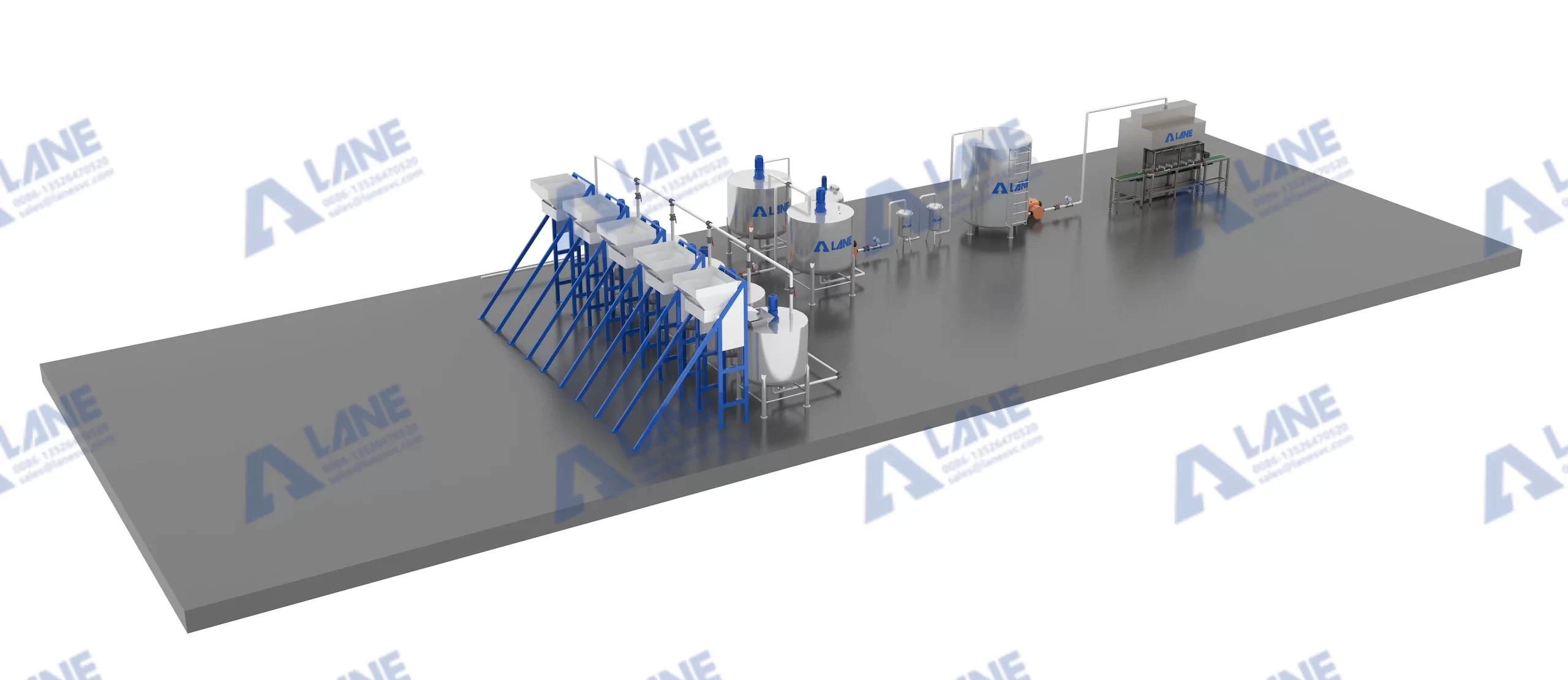

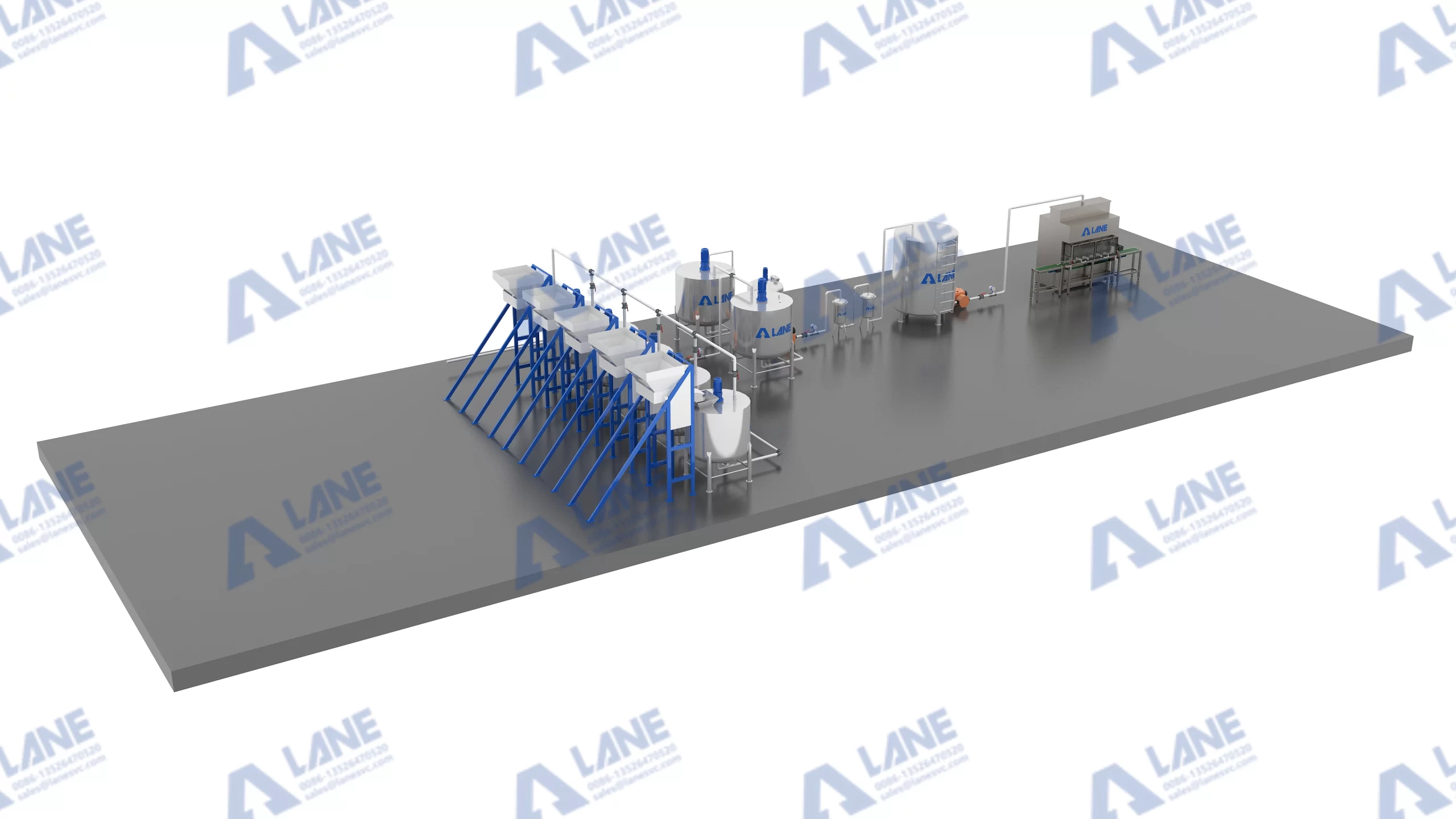

Behind each bottle or barrel of liquid fertilizer, there is a complete set of advanced equipment: mixing tanks, metering pumps, filtration systems and packaging lines. These devices together form a liquid fertilizer manufacturing equipment system, ensuring stable, efficient and scalable production. For producers who are interested in entering or expanding the liquid fertilizer market, choosing the right equipment is the foundation of success.

Precision Agriculture: Modern farms use irrigation systems and drones for nutrient delivery. Liquid fertilizers integrate seamlessly with these technologies.

Faster Nutrient Uptake: Foliar sprays and fertigation allow crops to absorb nutrients directly through leaves and roots.

Customization: Producers can formulate specialized blends for different crops, soils, and climate conditions.

Sustainability: Liquid fertilizers allow recycling of organic waste (molasses, fish protein, yeast extracts) into market-ready products.

The trend toward liquid fertilizers has created a rising demand for liquid fertilizer manufacturing equipment, which enables both large agro-industries and smaller cooperatives to keep pace with market needs.

Raw Material Mixing Tanks

The starting point of production. These tanks dissolve base materials like urea, ammonium phosphates, and potassium salts. Heating jackets and powerful agitators accelerate solubility and prevent residue build-up.

Main Mixing Tanks

Here, bulk blending takes place. Continuous stirring ensures homogeneity, while PLC systems monitor temperature, density, and pH for consistent results.

Additive Mixing Tanks

Specialized micro-nutrients, chelating agents, stabilizers, and bio-stimulants are added at this stage. By isolating these ingredients, the equipment prevents early degradation.

Filtration Units

Industrial filtration is crucial for liquid fertilizer. By removing insoluble particles, these dual filters ensure the final product flows smoothly in irrigation systems and storage tanks.

Automated Dosing and Control Systems

Precision dosing pumps and PLC controls allow manufacturers to create multiple formulations with accuracy. Recipes can be pre-programmed for consistency.

Filling and Packaging Systems

From 500 ml bottles for retail markets to IBC tanks for bulk supply, filling machines complete the process. Automated labeling and coding improve traceability and branding.

The choice of equipment influences not just efficiency but also competitiveness. With advanced liquid fertilizer manufacturing equipment, producers achieve:

Scalability: From pilot plants of 1,000 liters/day to industrial lines exceeding 50,000 liters/day.

Export Readiness: Meeting global quality standards through precise formulations and packaging.

Brand Differentiation: Ability to launch customized blends for niche crops like coffee, grapes, or greenhouse vegetables.

Cost Reduction: Automated systems reduce labor and energy waste, increasing overall profitability.

In India, greenhouse farming has expanded rapidly. A cooperative in Karnataka invested in LANE’s liquid fertilizer manufacturing equipment to supply customized nutrient solutions for tomato and cucumber production. Using automated dosing systems, they created different formulas for each crop growth stage. The result was a 20% increase in yield and reduced fertilizer waste. Farmers now apply nutrients through drip irrigation directly from on-site storage tanks, improving efficiency and lowering costs.

Brazil’s sugar and ethanol industries generate massive volumes of molasses and vinasse as byproducts. A forward-looking agribusiness partnered with LANE to install a liquid fertilizer manufacturing line that recycled these wastes into potassium-rich biofertilizers. The system included filtration units and additive mixing tanks to stabilize the product for export. Today, the company not only supports sustainable agriculture but also earns additional revenue from what was once an environmental burden.

These two cases show how liquid fertilizer manufacturing equipment can be adapted to both small farmer groups and major agro-industrial operations. Whether producing customized nutrient blends on a local scale or recycling industrial byproducts into export-ready fertilizers, the equipment proves versatile, efficient, and vital for sustainable agriculture.

Custom Engineering: Tailored plant designs that match raw materials, capacity, and market goals.

High-Quality Materials: Stainless steel, anti-corrosive linings, and food-grade finishes ensure durability.

Automation: PLC-controlled mixing, dosing, and filling reduce human error.

Turnkey Service: From concept and layout to installation and after-sales support.

Global Experience: Proven track record across Asia, Africa, South America, and Europe.

LANE’s approach ensures that producers gain more than machines—they gain integrated systems that improve efficiency, profitability, and sustainability.

Product Consistency: Uniform nutrient concentration in every batch.

Time Savings: Automated systems shorten production cycles.

Market Access: Ability to sell into premium and export markets.

Sustainability: Converts agro-industrial byproducts into eco-friendly fertilizer.

Long-Term Profitability: Reduces labor costs while maintaining high throughput.

Q1: What capacities are available?

From small 500 L/day pilot systems to industrial lines producing 50,000 L/day.

Q2: Can organic inputs be used?

Yes. Fish protein, molasses, and yeast extracts can all be processed.

Q3: How do I ensure product stability?

Through proper pH adjustment, filtration, and stabilizer additives introduced with the right equipment.

Q4: Is the equipment suitable for both fertigation and foliar fertilizers?

Yes. Systems are designed to create products for multiple application methods.

Q5: What support does LANE provide?

LANE offers plant design, manufacturing, installation, operator training, and global after-sales service.

The rise of liquid fertilizers is transforming agriculture worldwide, and liquid fertilizer manufacturing equipment is at the heart of this transformation. From raw material preparation to final packaging, each stage requires precision, efficiency, and reliability.

LANE’s expertise and global experience make it a trusted partner for enterprises investing in liquid fertilizer production. With advanced technology and turnkey solutions, producers can create high-quality, sustainable fertilizers that meet the demands of modern farming and international markets.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Leave a Comment

LANE has more than 500 successful cases and is committed to providing customers with first-class solutions, high-end machinery and equipment, and one-stop pre-sales, sales and after-sales comprehensive customer service.