Organic vs. Chemical: Which Liquid Fertilizer Machine for Agriculture is Right for You?

The modern agricultural landscape is defined by efficiency and precision. Choosing the right liquid fertilizer machine for agriculture impacts crop yield, soil health, and long-term farm profitability. This is a pivotal piece of technology that allows farmers and producers to create customizable high-quality fertilizers on demand. But a question that arises when creating this production line is: Which fertilizer to produce? Organic or chemical fertilizers. Which will suit best for your operation?

LANE Heavy Industry Co.,Ltd., a trusted name as the producer of liquid fertilizer machine for agriculture industry, offers specialized solutions for both fertilizer types. In this article we will guide you through the key differences to help you select the perfect liquid fertilizer machine for agriculture for your specific operation.

The core difference and primary factor separating these two production lines is raw materials input.

Organic Liquid Fertilizer Production: Organic liquid fertilizers use organic matter as their base. Common raw materials include animal manure (poultry, cow, pig), agricultural waste, food processing byproducts, biogas slurry and green waste. In this process we break down these complex organic materials into a stable, nutrient-rich liquid.

Chemical Liquid Fertilizer Production: Chemical liquid fertilizers use synthetic raw materials as their base. The raw materials include mineral salts like ammonium nitrate, urea, potassium chloride, and phosphoric acid. The goal is to create a solution with a precise NPK (Nitrogen, Phosphorus, Potassium) ratio.

These fundamental differences in raw materials lead to different production processes for your liquid fertilizer machine for agriculture.

Producing liquid fertilizer using organic raw materials involves a biological procedure. It demands machinery of performing decomposition, homogenization and separation.

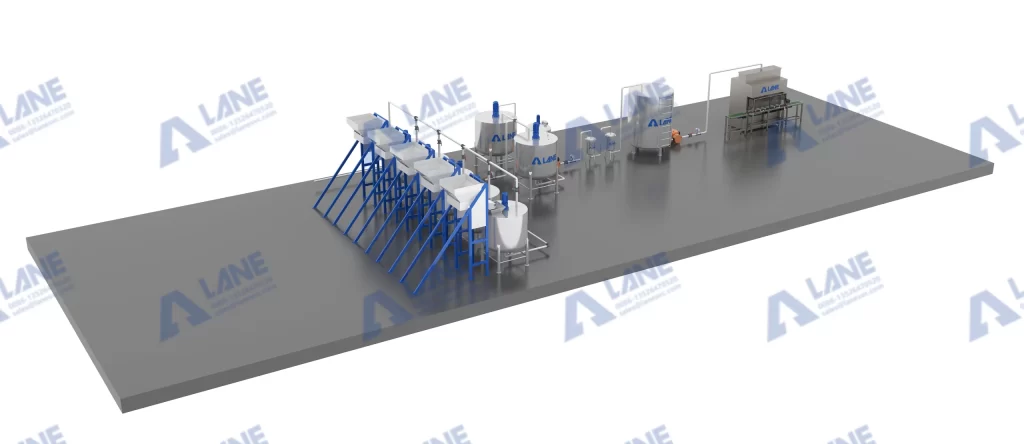

LANE has a production line solution for organic liquid fertilizer. A production line for organic liquid fertilizer will have:

Crushing and Mixing: A crusher is essential for organic material fermentation. Before the raw materials are sent into the fermentation tank, they are crushed with LANE crusher so that they form a slurry. This makes them easier to ferment.

Anaerobic or Aerobic Fermentation Tanks: This is the main organic liquid fertilizer machine for agriculture. This machine is coated internally and externally with acid-resistant layers to withstand harsh organic compounds. They hold organic slurry for a set period, allowing beneficial microorganisms to break down the material. LANE fermentation tank is equipped with agitation systems, which ensures even fermentation and prevents settling.

Liquid-Solid Separators: After fermentation the liquid needs to be separated from the solids. The mixture is passed through a separator like LANE screw press to remove solid fibers.

Polishing and Storage: The liquid goes through further mixing and filtration tanks to achieve the desired clarity. Then the final liquid fertilizer is stored in an agitated storage tank where it maintains consistency before packing or use.

Organic liquid fertilizer is Best For:

Creating chemical fertilizer from synthetic raw material is a chemical homogeneous process. This production line includes industrial mixing and dissolution process. The raw material for chemical liquid fertilizer machine for agriculture needs to have corrosive resistance.

A standard chemical liquid fertilizer production line would feature:

Reaction/Mixing Tanks: These are the core machines of chemical fertilizers production line. In these tanks raw materials are dissolved in water or other liquid solutions. They are equipped with powerful high-shear agitators to ensure complete and rapid dissolution, preventing crystallization. The inside is made of SS316 steel.

Heating/Cooling Systems: The jacketed mixing tanks contain temperature control for homogeneous mixing. Some raw materials mix well in high temperature and some raw materials lose their properties in high temperature. To ensure that raw materials are in right property LANE provides jacketed tank for raw material mixing.

Filtration Systems: Filters are used to remove any undissolved impurities or contaminants that could clog application equipment. Without filter the product may look cloudy.

Precise Dosing and Storage: After filtering, the final solution is transferred to agitated storage tanks. Here mild agitation is used to maintain homogeneity of the liquid fertilizer. Then it is transferred to packing machine.

Farming operations focused on immediate nutrient like aquaponics

To make a decision about which liquid fertilizer machine for agriculture to buy you first have to consider few points. Ask yourself these questions:

The right partner is essential for liquid fertilizer machine for agriculture. Whether you choose an organic or chemical line, without the right machinery your production line will face bottlenecks. LANE specializes in engineering and manufacturing custom liquid fertilizer machine for agriculture lines. We consider your raw materials, output goals, and budget before we create a solution for you.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Leave a Comment

Latest Posts

LANE has more than 500 successful cases and is committed to providing customers with first-class solutions, high-end machinery and equipment, and one-stop pre-sales, sales and after-sales comprehensive customer service.