Reduce Waste and Improve Consistency with a Centralized Liquid Fertilizer Line for Greenhouse Fertilizers

Greenhouse farming, as a pillar of modern agriculture, pursues high yields and high-quality crops. For commercial greenhouse operators, precision is profit, and inconsistent nutrient delivery and fertilizer waste are profit killers. They lower and uneven crop quality, and increase input costs.

The traditional greenhouse cultivation system has always had problems such as serious waste and unstable nutrient supply. A liquid fertilizer line for greenhouse fertilizers has become a key breakthrough to solve these pain points. This system isn’t just an upgrade; it’s an investment in uniformity, control, and bottom-line efficiency.

LANE Heavy Industry, with its professional R&D team and experienced equipment solutions, has created the application of this efficient and environmentally friendly system.

Traditionally, in greenhouses, they blend the fertilizer manually and rely on inefficient irrigation systems. This creates uneven nutrient ratios and inaccurate dosage. A slight variation in mixing can lead to differences in electrical conductivity (EC) and pH across your greenhouse. A large amount of unabsorbed fertilizer flows into the soil or is lost with water, which causes resource waste and pollution.

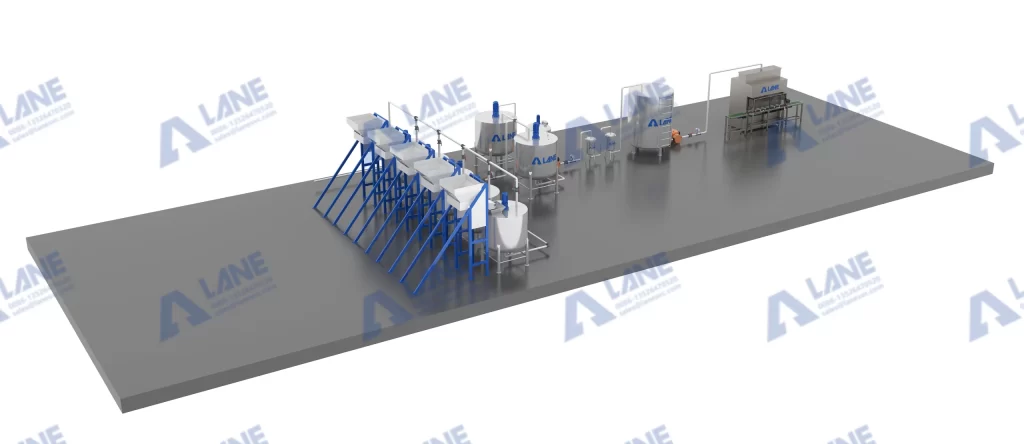

A centralized liquid fertilizer line for greenhouse fertilizers, designed and developed by LANE Heavy Industry, can integrate fertilizer blending, transportation, and application. It creates a harmonious situation in the greenhouse.

In a traditional greenhouse system, waste occurs at every step. Wastage like overuse, spillage during manual transfer, and disposal of unused solutions is wasting money, leaching directly from your operation.

A professionally designed and engineered liquid fertilizer line for greenhouse fertilizers consolidates your liquid fertilizer production and delivery into a single, automated hub.

Precision at Scale: The centralized system designed by LANE uses high-accuracy dosing pumps and injectors to deliver the fertilizer to every farming zone, regardless of the greenhouse size. It ensures every farming zone receives the same amount of nutrients, promoting uniform crop development.

Drastic Reduction in Material Waste: By creating an automated dilution and injection system, you eliminate batch mixing errors and spillage. You can control through the PLC system to draw the exact ratios of liquid fertilizers needed for each irrigation cycle.

Labor Efficiency and Safety: This reduces your labor cost and reduces the physically demanding aspects of greenhouse work. This minimizes worker exposure to concentrated chemicals and creates a safer work environment.

Enhanced Data and Control: Modern systems, integrated with computerized climate systems, allow fertilizer recipes (EC/pH) to be automatically adjusted based on light levels. This allows optimal nutrients during different growth stages or seasons. You collect data and create optimal solutions tailored to your fertilizer production.

Designing and implementing a reliable system requires industrial-grade machinery components capable of handling corrosive fertilizers. Partnering with LANE Heavy Industry will eliminate this problem. They create the production line with corrosion-resistant SS304 or SS316 steel.

LANE Heavy Industry specializes in durable, corrosion-resistant solutions for agricultural fluid handling. We understand that a flimsy setup will lead to leaks, pump failures, and inconsistent dosing. Our engineering approach to liquid fertilizer lines for greenhouse fertilizers includes:

In addition to reducing waste and improving consistency, LANE Heavy Industry’s liquid fertilizer line for greenhouse fertilizers also has the characteristics of strong adaptability and easy operation. The equipment can be customized according to the area of the greenhouse, the type of crops, and the local water quality conditions.

The cost of investment in a centralized liquid fertilizer line for greenhouse fertilizers pays dividends through multiple channels.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Leave a Comment

Latest Posts

LANE has more than 500 successful cases and is committed to providing customers with first-class solutions, high-end machinery and equipment, and one-stop pre-sales, sales and after-sales comprehensive customer service.