Optimizing the Production Process of Liquid Fertilizer from Organic Wastewater

Table of Contents

Climate change is accelerating, increasing the global emphasis on environmental protection and the promotion of sustainable agriculture. The population is also growing day by day. Ensuring food security for a growing population while minimizing its environmental footprint is a difficult task.

At the same time, industries and municipalities worldwide are struggling with the costly and complex issue of treating vast volumes of organic wastewater. This presents a powerful opportunity: transforming waste into Liquid Fertilizer from Organic Wastewater.

Liquid Fertilizer from Organic Wastewater is a product which combines environmental governance and agricultural production. It solves the pollution problem of organic wastewater from livestock breeding, food processing, and domestic sources. It also provides high-quality organic nutrients for agricultural production.

The traditional production process of this fertilizer is plagued by low conversion efficiency, unstable product quality, and high energy consumption. This restricted it from large-scale production.

Modern technology by LANE moves beyond the concept of mere “waste treatment.” The production of organic Liquid Fertilizer from Organic Wastewater represents the flag of the circular economy. It recovers valuable nitrogen, phosphorus, potassium, and micronutrients from wastewater and closes the nutrient loop, reducing reliance on energy-intensive synthetic fertilizers.

However, the process of converting heterogeneous, variable wastewater into a consistent, safe, and market-ready Liquid Fertilizer from Organic Wastewater is filled with technical hurdles which are impossible to solve without expert help. LANE Heavy Industry provides a full turnkey service that will not only help you with the production line but will also provide your technicians with training.

A rudimentary digestion of organic wastewater might yield a nutrient-rich slurry, but it falls short of being a reliable fertilizer. The production challenges include:

Overcoming these barriers requires an integrated, technology-driven approach to the entire production chain.

ANE Heavy Industry, a leader in organic fertilizer machine manufacturing and process engineering, has developed a production line that can efficiently transform the production of Liquid Fertilizer from Organic Wastewater into a precision industrial operation.

3.1. Phase 1: Advanced Pre-Treatment & Feedstock Conditioning

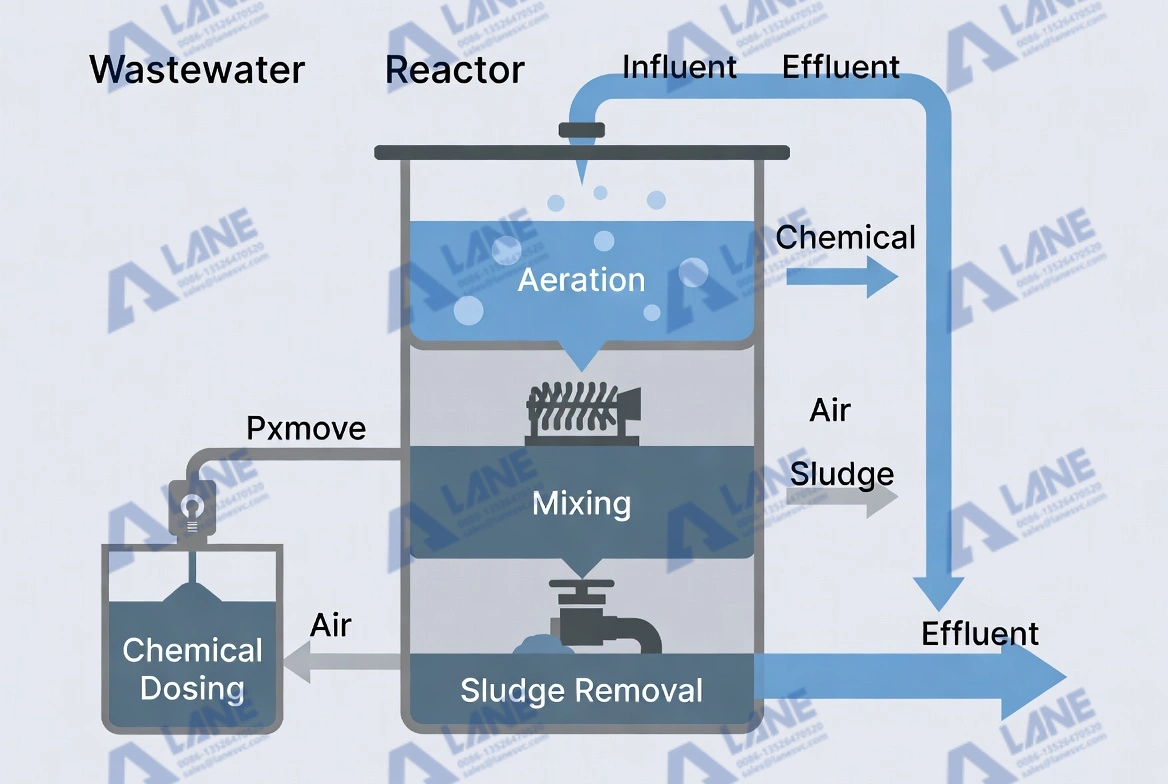

Optimization starts at the very beginning of the production system. LANE’s system uses smart screening and grit removal to protect downstream equipment. We use our advanced Dynamic Equalization and Blending Tank System in this phase. This system intelligently mixes incoming wastewater streams to create a consistent feedstock, eliminating the problem of variability.

This tank is equipped with real-time sensors for COD (Chemical Oxygen Demand), pH, and total solids. This allows the operator or machine to auto-adjust the liquids, ensuring the biological reactor receives an optimal “meal” every time. This is the first critical step in producing a standardized Liquid Fertilizer from Organic Wastewater.

3.2. Phase 2: Controlled Anaerobic Digestion & Nutrient Liberation

In this phase, the organic matter is broken down. LANE replaces simple lagoon systems with their High-Rate Thermophilic Anaerobic Digesters. These insulated, heated reactors operate at elevated temperatures (55-60°C). This accelerates biodegradation, enhances pathogen kill, and increases biogas yield as a by-product.

LANE integrates a system for precise monitoring of temperature, hydraulic retention time (HRT), and volatile fatty acids (VFAs). With this level of control, process upset is prevented, the conversion of organic nitrogen to plant-available ammonium is maximized, and efficient phosphorus release is ensured. This directly optimizes the nutrient density of the resulting Liquid Fertilizer from Organic Wastewater.

3.3. Phase 3: Precision Post-Digestion Processing & Stabilization

The digestate from the previous phase is nutrient-rich but far from a finished product. LANE’s optimization focuses on refinement:

3.4. Phase 4: Smart Packaging, Storage & IoT Monitoring

The last phase is final product handling. The finished product is sent to a storage tank where it is placed for two weeks to stabilize as Liquid Fertilizer from Organic Wastewater. We provide corrosion-resistant storage tanks specifically designed for long-term storage of Liquid Fertilizer from Organic Wastewater. Our integrated PLC platform is the brain of the operation. It real-time controls and tracks everything from digester health to final nutrient levels (NPK) in storage tanks via a digital dashboard. This allows for batch traceability and quality assurance for every liter of Liquid Fertilizer from Organic Wastewater.

Implementing a LANE-optimized production line delivers an efficient system with measurable profits.

The promotion of the production process of Liquid Fertilizer from Organic Wastewater is not only a need for environmental governance but also a path to promote agricultural green development. It is an emerging pillar of sustainable agriculture and industrial efficiency. However, its full potential lies in the systematic optimization of the entire production process for Liquid Fertilizer from Organic Wastewater.

LANE Heavy Industry, with its technological innovation, has broken through the bottlenecks of the traditional process. It enables the highly efficient conversion of organic wastewater into high-quality liquid fertilizer. By partnering with LANE Heavy Industry, farmers and agribusinesses can overcome the challenges of scale, consistency, and safety.

Q1: What types of organic wastewater are best suited for producing this liquid fertilizer?

A: A wide range of organic wastewaters are ideal, including effluent from food and beverage processing (dairy, brewery, slaughterhouse), agricultural runoff, digestate from biogas plants, and certain municipal wastewater streams. LANE Heavy Industry conducts a thorough feedstock analysis to design the optimal system for each source.

Q2: How does the quality of this liquid fertilizer compare to synthetic fertilizers?

A: Optimized Liquid Fertilizer from Organic Wastewater provides immediately available nutrients (like ammonium) similar to synthetics, but also contains valuable organic matter, micronutrients, and beneficial compounds that improve soil health and structure over time. This is a benefit synthetic liquid fertilizer cannot offer.

Q3: Is the fertilizer safe for all crops?

A: When produced through an optimized process that includes proper stabilization and pathogen removal (like LANE’s UV system), the fertilizer is safe for a broad range of crops, including row crops, orchards, and non-contact forage.

Q4: What happens to the biogas produced during digestion?

A: The biogas (primarily methane) is a valuable by-product. It can be used in a combined heat and power (CHP) unit to generate electricity and heat for the production facility, significantly reducing operational costs and carbon footprint.

Q5: Can LANE’s system be retrofitted to an existing wastewater treatment plant?

A: Yes. A core strength of LANE Heavy Industry’s approach is modularity. Our components like the advanced control systems, stabilization reactors, and separation units can often be integrated into existing infrastructure to upgrade performance and enable Liquid Fertilizer from Organic Wastewater production without a complete rebuild.

Q6: What is the typical payback period for investing in such an optimized system?

A: The payback period varies based on scale, feedstock, and local fertilizer/energy prices. However, by combining revenue from fertilizer sales, energy savings from biogas, and reduced waste disposal costs, a well-designed LANE system typically achieves a return on investment within 3 to 4 years.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Leave a Comment

LANE has more than 500 successful cases and is committed to providing customers with first-class solutions, high-end machinery and equipment, and one-stop pre-sales, sales and after-sales comprehensive customer service.