Liquid Fertilizer from Fermented Soybean Meal: A Sustainable Solution for Modern Agriculture

As farmers and agribusinesses seek more sustainable ways to nourish crops, the use of organic inputs is gaining momentum. Among the many options, liquid fertilizer from fermented soybean meal has emerged as an efficient, nutrient-rich, and eco-friendly choice. Derived from soybean by-products, this fertilizer provides essential amino acids, nitrogen, and trace minerals that support plant growth.

Unlike synthetic fertilizers, liquid fertilizer from fermented soybean meal improves soil health while supplying nutrients in a readily available form. Its liquid state makes it highly compatible with irrigation systems, including drip fertigation, and its organic composition ensures long-term agricultural sustainability.

Rich in Nitrogen and Amino Acids: Soybean meal is a by-product of soybean oil extraction and contains high levels of protein. Fermentation breaks down these proteins into amino acids and peptides, which plants can easily absorb.

Eco-Friendly Recycling: Instead of discarding soybean meal, processing it into liquid fertilizer reduces agricultural waste and adds value to by-products.

Slow and Steady Nutrient Release: The fermentation process ensures nutrients are released gradually, providing consistent nourishment for crops.

Compatibility with Organic Farming: Since it is derived from natural ingredients, liquid fertilizer from fermented soybean meal meets the requirements of organic farming standards in many countries.

Improved Soil Biology: Fermentation promotes beneficial microbes, which enhance soil fertility and resilience.

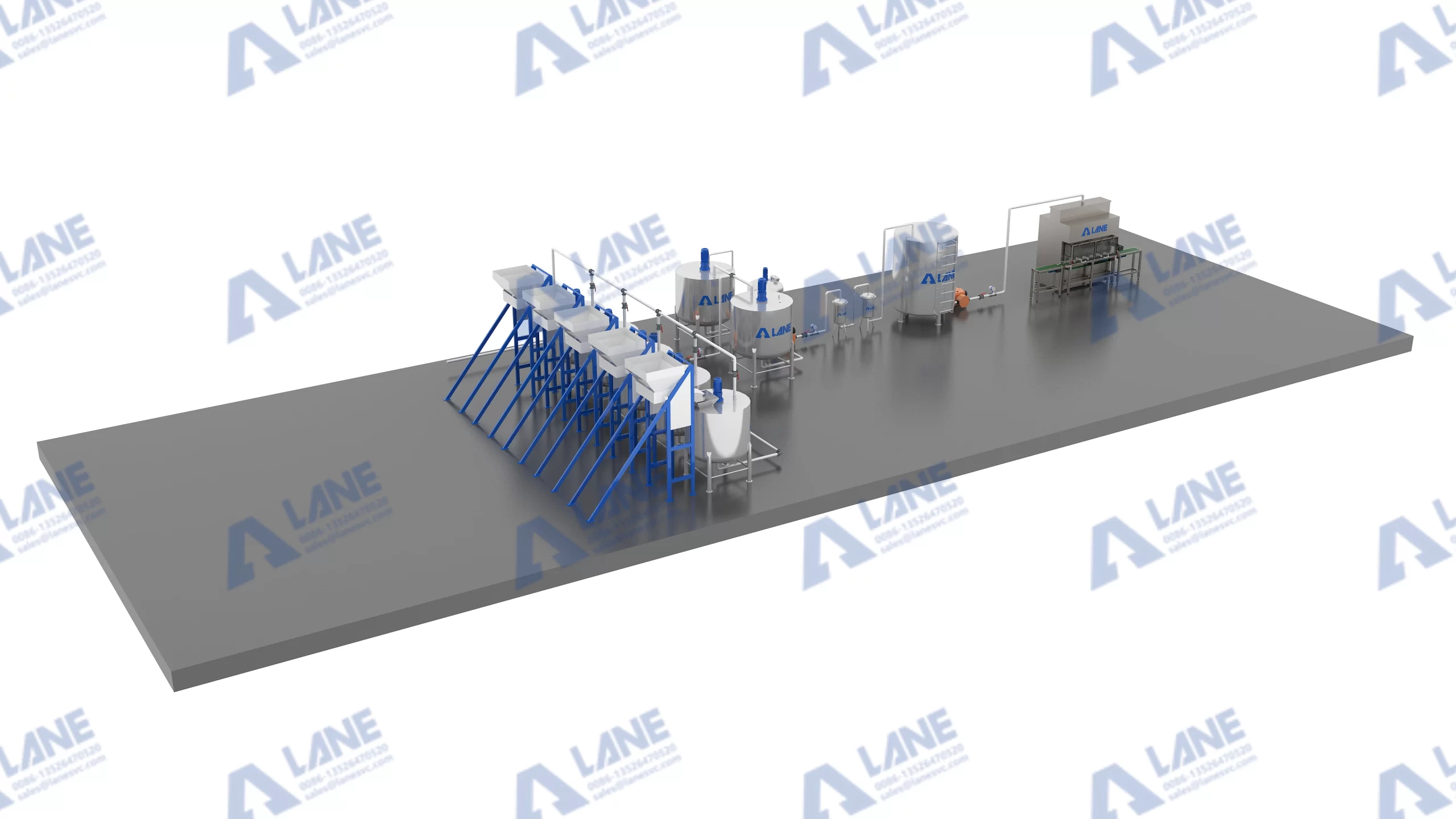

The production of liquid fertilizer from fermented soybean meal involves several stages, supported by specialized equipment:

1.Raw Material Preparation

Soybean meal is collected and pre-processed to remove impurities. An inclined dewatering machine can be used if the material contains excess moisture.

2.Crushing and Mixing

The soybean meal is passed through a crushing machine to reduce particle size, then blended in a stainless steel mixing tank. Additives such as molasses or microbial cultures are introduced at this stage to support fermentation.

3.Fermentation

The mixture is transferred into fermentation tanks, where controlled microbial activity breaks down proteins into amino acids. Temperature, pH, and oxygen levels are carefully monitored to ensure efficient nutrient conversion.

4.Dual Filtration

After fermentation, the liquid is processed through a dual filter to remove solids and produce a clean, uniform liquid fertilizer suitable for drip irrigation or foliar application.

5.Stabilization

Stabilizers, pH regulators, and beneficial microbes are added in a stainless steel mixing tank to improve shelf life and enhance fertilizer performance.

6.Quality Control

Samples are tested in a laboratory unit to ensure nutrient concentrations, microbial safety, and compliance with organic farming standards.

7.Packaging and Storage

The final product is stored in stainless steel tanks and packaged using an automatic liquid filling machine, available in bulk containers or smaller bottles for different market needs.

Case Example: Vegetable Farming in China

In China’s Shandong province, a group of vegetable growers adopted liquid fertilizer from fermented soybean meal as part of their fertigation program. The farmers reported a 20% increase in yields for cucumbers and tomatoes, along with improved soil texture. By replacing chemical fertilizers with this organic alternative, they reduced costs and obtained certification for organic produce, increasing their market value.

Case Example: Soybean By-Product Utilization in Brazil

Brazil, one of the largest soybean producers, faces challenges in managing by-products like soybean meal. A processing facility established a liquid fertilizer from fermented soybean meal plant near major soybean oil mills. The fertilizer was distributed to maize and coffee growers through cooperatives, where it improved crop resilience to drought and reduced the need for imported fertilizers. The initiative also created new revenue streams for soybean processors.

Applications in Agriculture

Fruit Orchards: Supports healthy growth and enhances flavor and color development.

Vegetable Farms: Improves yield, reduces chemical residues, and enhances soil fertility.

Cereal Crops: Provides a steady nutrient supply during growth stages.

Greenhouses: Compatible with drip irrigation and foliar spraying systems.

Organic Farming Systems: Meets organic certification standards for eco-conscious markets.

Market Potential of Liquid Fertilizer from Fermented Soybean Meal

The global agricultural inputs market is undergoing a shift, with rising demand for bio-based and eco-friendly fertilizers. Liquid fertilizer from fermented soybean meal fits perfectly into this trend, offering both nutritional efficiency and sustainability.

Rising Demand for Organic Farming Inputs

With more consumers choosing organic products, farmers require inputs that meet organic certification standards. Fertilizers derived from fermented soybean meal are natural, safe, and widely accepted in organic agriculture.

Integration with Precision Irrigation

As drip irrigation and fertigation systems expand worldwide, the demand for liquid fertilizers compatible with these technologies continues to grow. Liquid fertilizer from fermented soybean meal is highly soluble and perfectly suited for precision farming.

Abundant Raw Material Supply

Countries like Brazil, the United States, and Argentina produce massive amounts of soybean by-products. Establishing fertilizer production plants near soybean oil mills creates a closed-loop system with strong economic potential.

Export Opportunities

High-quality liquid organic fertilizers are increasingly in demand in Europe, North America, and Asia. Producers of liquid fertilizer from fermented soybean meal can target not only domestic markets but also global trade, leveraging the strong push for sustainable inputs.

Supportive Policies

Many governments provide subsidies or incentives for organic fertilizer production, making it easier for companies and cooperatives to invest in these facilities.

Together, these factors indicate that the market potential for liquid fertilizer from fermented soybean meal is strong and expanding, offering significant opportunities for both small-scale farmers and large agribusiness ventures.

Future Outlook

The demand for organic liquid fertilizers is expected to rise globally as governments, consumers, and agribusinesses push for sustainable farming. With soybean meal abundantly available as a by-product, scaling up liquid fertilizer from fermented soybean meal production has enormous potential. Future advancements may include automation, IoT-based monitoring of fermentation, and integration with renewable energy systems to further reduce production costs and environmental impacts.

The liquid fertilizer from fermented soybean meal offers farmers and agribusinesses a powerful tool to improve crop yields, enhance soil health, and promote sustainability. By transforming soybean by-products into high-value liquid fertilizer, this technology supports circular agriculture and reduces environmental burdens.

Real-world cases in China and Brazil show its adaptability across different farming systems, from small vegetable farms to large cooperatives. As global agriculture continues to shift toward eco-friendly practices, liquid fertilizer from fermented soybean meal will play an increasingly important role in feeding the world sustainably.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Leave a Comment

LANE has more than 500 successful cases and is committed to providing customers with first-class solutions, high-end machinery and equipment, and one-stop pre-sales, sales and after-sales comprehensive customer service.