Maximizing Your Harvest: Why Liquid Fertilizer for Vegetable Greenhouses is the Future of Farming

Hey there! If you’ve ever walked into a professional vegetable greenhouse, you know that amazing feeling—the smell of fresh earth, the vibrant green leaves, and that perfect, controlled humidity. It feels like a high-tech nursery for plants. But behind those rows of juicy tomatoes and crisp cucumbers, there is a lot of science happening. Specifically, growers are moving away from old-school dry pellets and embracing the power of liquid fertilizer for vegetable greenhouses to get the best results possible.

As a student looking at the intersection of agriculture and technology, I find it fascinating how much “food for plants” has changed. It isn’t just about throwing some dirt around anymore. It’s about precision, chemistry, and—most importantly—the incredible machinery that makes it all possible.

You might wonder, “Why go liquid?” Well, think about it like this: if you’re really thirsty, do you want to eat a dry saltine cracker or drink a refreshing glass of water? Plants are the same way. Liquid fertilizer for vegetable greenhouses provides nutrients in a form that plants can “drink” almost instantly. This means faster growth, healthier roots, and less waste.

In a greenhouse, space is money. You want your vegetables to grow quickly and uniformly. When you use a high-quality liquid fertilizer for vegetable greenhouses, you can automate the feeding process through irrigation systems (often called fertigation). This ensures every single plant gets the exact same amount of nutrition. No more “lucky” plants and “hungry” plants—just a sea of perfect produce.

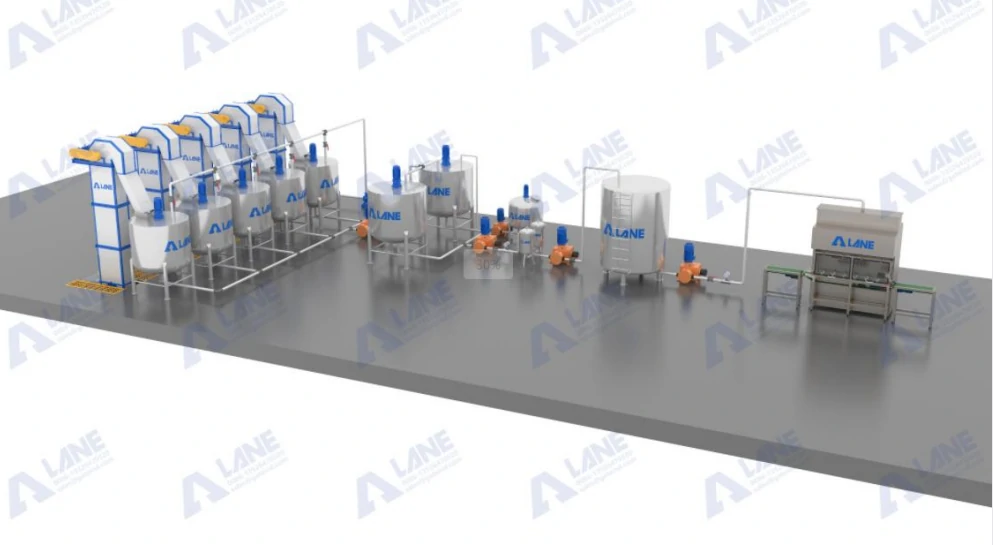

While the fertilizer itself is great, the real magic happens back at the factory. To create a stable, effective liquid fertilizer for vegetable greenhouses, you can’t just stir a pot with a spoon. You need a sophisticated production line. Let’s break down the “behind-the-scenes” equipment that turns raw chemicals into farm-ready liquid gold.

Before the liquid is even liquid, we start with raw materials. These can be powders, salts, or concentrated minerals. To ensure the liquid fertilizer for vegetable greenhouses doesn’t clog up those tiny greenhouse sprayers, the raw materials must be pure. We use specialized crushing and sifting machines to make sure every ingredient is fine and ready to dissolve.

This is the heart of the operation. You need a massive stainless steel mixing tank equipped with high-speed agitators. Why? Because some nutrients don’t like to mix! A high-shear mixer forces the elements together, creating a stable “emulsion” or solution. This ensures that when a farmer buys a bottle of liquid fertilizer for vegetable greenhouses, the nutrients don’t all settle at the bottom like old salad dressing.

Greenhouse irrigation lines are incredibly delicate. Even a tiny speck of dust can cause a backup. That’s why the production line includes dual-filter. The liquid fertilizer for vegetable greenhouses passes through ultra-fine mesh filters to remove any undissolved solids, ensuring it’s “greenhouse-safe.”

Once the liquid is perfect, it needs a home. Automated filling machines measure out the exact volume into jugs or drums. Then, high-speed capping machines seal them tight to prevent leaks or contamination. It’s a fast-paced, rhythmic process that’s honestly pretty cool to watch.

When we talk about the machinery that builds these systems, we take it personally. At LANE, we don’t just sell machines; we provide the backbone for modern agriculture. We’ve spent years perfecting the technology required to produce premium liquid fertilizer for vegetable greenhouses.

We know that every factory has different needs. Maybe you’re working in a tight space, or maybe you need to produce 10,000 liters an hour. That’s where our company shines. We specialize in equipment customization. Whether you need a specific layout or a unique mixing speed to handle a secret nutrient formula, we can design a solution that fits your exact goals.

Our team at LANE doesn’t just ship a box and disappear, either. We are proud to offer full liquid production line installation and comprehensive after-sales service. If you have a question at 2:00 AM or need a part replaced, we are there for you. We believe that our success is tied to your success.

Quality isn’t just a buzzword for us—it’s a promise. All of our equipment meets strict ISO9001 and CE quality standards. This means when you use LANE machinery to produce liquid fertilizer for vegetable greenhouses, you are using tools that are safe, durable, and globally recognized for excellence. Our focus on precision ensures that your final product has the exact consistency and nutrient density required for high-end greenhouse farming.

One thing I’ve learned is that producing liquid fertilizer for vegetable greenhouses is a lot like baking a very complicated cake. If the temperature is off by five degrees or the mixing time is short by two minutes, the whole batch could be ruined.

This is why advanced control systems are so important. Modern production lines use PLC (Programmable Logic Controllers) to monitor every step. This “brain” of the machine ensures that the pH levels are perfect and the concentration is exact. For a farmer, using a liquid fertilizer for vegetable greenhouses that was made on a precision line means they can trust their plants won’t get “burned” by a batch that was too strong.

In my geography and science classes, we talk a lot about the environment. One of the best things about liquid fertilizer for vegetable greenhouses is that it’s much more eco-friendly than older methods. Because it’s applied directly to the roots via pipes, there is almost zero runoff. This keeps our rivers clean and ensures that every drop of fertilizer is actually used by the plant.

As the world’s population grows, we need more food from less land. Greenhouse farming is the answer, and high-quality liquid nutrients are the fuel for that answer. By investing in the right production equipment, manufacturers can provide the high-performance liquid fertilizer for vegetable greenhouses that modern farmers crave.

Whether you are a farmer looking to upgrade your nutrient game or a manufacturer looking to build a world-class factory, the goal is the same: healthy plants and a healthy planet. The transition to liquid fertilizer for vegetable greenhouses is a huge step in the right direction.

It’s an exciting time to be in this industry! With the combination of smart chemistry and the heavy-duty, customized machinery provided by teams like ours at LANE, the future of farming looks brighter (and greener) than ever.

If you’re ready to take your production to the next level, why not look into how a professional production line can change your business? From the first mixing tank to the final sealed bottle, we’ve got the expertise to help you grow.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Leave a Comment

Latest Posts

LANE has more than 500 successful cases and is committed to providing customers with first-class solutions, high-end machinery and equipment, and one-stop pre-sales, sales and after-sales comprehensive customer service.