Liquid Fertilizer for Cash Crops: Reliable Equipment

Producing Liquid fertilizer for cash crops has become an important part of modern agriculture. Farmers need fertilizers that are easy to use, work quickly, and fit many different crop types. At the same time, producers of these fertilizers must create clean, balanced, and safe products.

This requires a clear understanding of what economic crops need and the machines that support stable production. With the right setup, manufacturers can make a high-quality fertilizer that improves growth and brings better harvests to farmers.

Economic crops vary widely, but their fertilizer needs can be summarized into three easy points. These points apply across fruits, vegetables, herbs, flowers, and many other crops grown for profit. When producers keep these ideas in mind, they can make Liquid fertilizer for cash crops that works well in most fields.

Different Crops Absorb Nutrients Differently

Each crop type takes in nutrients in its own way. Leafy crops absorb nutrients quickly through their leaves, while fruit crops may need stronger root feeding to support fruit size and sweetness. A well-made Liquid fertilizer for cash crops must be smooth, clean, and easy for plants to absorb through both leaves and roots. Liquid form makes this easier because plants do not need to break down solid particles.

Crops Change Their Needs During Growth

Young plants need gentle nutrition to help early root development. Middle-stage crops need more balanced feeding, and mature crops may need extra potassium for fruit or flower development. Good producers make several formulas of Liquid fertilizer for cash crops, each designed for a different stage of growth. The machines used to make these formulas must mix ingredients evenly and keep the final product stable so farmers can trust what they apply.

Liquid Fertilizer Helps Improve Yield and Quality

Liquid fertilizers offer quick action because nutrients are already dissolved. This helps crops grow faster, stay healthier, and produce higher-quality results—sweeter fruits, stronger stems, greener leaves, and larger harvests. For this reason, many farmers now prefer Liquid fertilizer for cash crops, especially when growing high-value plants that need precise nutrition.

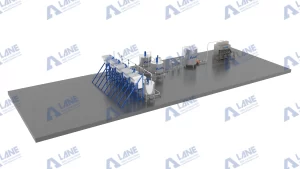

To make reliable Liquid fertilizer for cash crops, producers use several types of tanks and a UV sterilizer. These machines help mix, dissolve, clean, and package the fertilizer so that every batch is stable and safe for use. The process is simple, but each machine plays an important role.

Mixing Tank

The mixing tank is the starting point of production. Here, all the ingredients—nutrient powders, liquids, and additives—come together. The tank stirs everything until the mixture becomes smooth. Good mixing is the foundation of consistent Liquid fertilizer for cash crops because farmers expect each bottle to work the same way.

Dosing Tank

The dosing tank helps control the amount of each ingredient. It measures and adds the right quantity so the formula stays accurate. Balanced nutrients are essential for producing high-quality Liquid fertilizer for cash crops, and the dosing tank makes this possible without mistakes.

Some ingredients dissolve slowly at room temperature. The fermentation tank warms the mixture to help those materials dissolve more completely. This step improves the texture and stability of the fertilizer. A well-heated batch is smoother and easier for farmers to use in sprayers or irrigation systems.

Dual filters

After fermentation and mixing, the fertilizer flows into a dual filters. Tiny particles or impurities are removed here. Clear fertilizer protects farm equipment from clogs and improves plant absorption. Cleanliness is especially important in Liquid fertilizer for cash crops because farmers often use drip irrigation or foliar spraying.

UV Sterilizer

A UV sterilizer uses ultraviolet light to disinfect the liquid fertilizer. This process reduces harmful microbes without adding chemicals. It helps prevent spoilage, bad odors, and unwanted growth inside storage containers. Adding UV treatment increases the safety and shelf life of Liquid fertilizer for cash crops.

Storage Tank

Once cleaned and sterilized, the fertilizer stays in a storage tank. These tanks are made from materials that resist corrosion. Strong storage protects the fertilizer until it is ready to be packaged. Stable storage means stable quality.

Packaging Tank

When it is time to bottle or bag the fertilizer, the packaging tank ensures that each portion is filled correctly. Accurate packaging helps farmers trust the product they buy. A good packaging tank also keeps the work area clean and reduces waste.

The liquid production line for Liquid fertilizer for cash crops follows a simple and efficient flow. Ingredients go into the mixing tank, the dosing tank ensures the correct amounts, and the heating tank helps everything blend smoothly. The filtration tank cleans the mixture, while the UV sterilizer ensures safety. The storage tank holds the product until it is ready, and the packaging tank completes the final step. Each tank supports the next one, creating a smooth path from raw materials to finished fertilizer.

A key reason this process works so well is that the machines make each step predictable. Consistency in production means consistency in crop results. And for farmers growing valuable plants, consistency is essential.

Behind good fertilizer production is dependable equipment. Many producers choose machines from lane because the company offers strong advantages: more than 20 years of experience, cooperation with over 120 countries, and a 5-year warranty that protects long-term operation. These strengths help manufacturers produce Liquid fertilizer for cash crops with confidence. Reliable equipment keeps the production process steady, reduces breakdowns, and ensures the final product meets quality expectations.

The demand for Liquid fertilizer for cash crops continues to grow as farmers look for fast-acting and easy-to-use solutions. Understanding basic crop needs and using the right tanks and machines helps producers create fertilizers that improve both yield and quality. With well-designed equipment and strong support, the entire production process becomes more stable and efficient. As a result, farmers receive a high-value fertilizer they can trust, and producers gain long-term success in a competitive market.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Leave a Comment

Latest Posts

LANE has more than 500 successful cases and is committed to providing customers with first-class solutions, high-end machinery and equipment, and one-stop pre-sales, sales and after-sales comprehensive customer service.