From Pilot to Production: Key Stages in Launching a Liquid Fertilizer for Agriculture Line with LANE Heavy Industry

Liquid Fertilizer for Agriculture offers faster nutrient absorption, precise nutrient control, and improved crop yields. It can’t be compared to traditional slow-release solid fertilizers. Liquid Fertilizer for Agriculture is compatible with modern irrigation systems and you can create tailor-made blends for specific crop needs. For entrepreneurs and agribusinesses, launching a liquid fertilizer production line is a significant opportunity. But it also requires a systematic approach. To ensure efficiency, consistency, and compliance with industry standards, a partner like LANE Heavy Industry is essential. LANE Heavy Industry, a leading manufacturer of agricultural machinery, designs liquid fertilizer production lines to streamline each stage of the process.

This article outlines the key stages of launching a Liquid Fertilizer for Agriculture line with the help of equipment from LANE Heavy Industry.

Every project begins with a deep understanding of the customer’s unique goals. LANE focuses on analyzing the specific context of the manufacturer. Key discussions will cover:

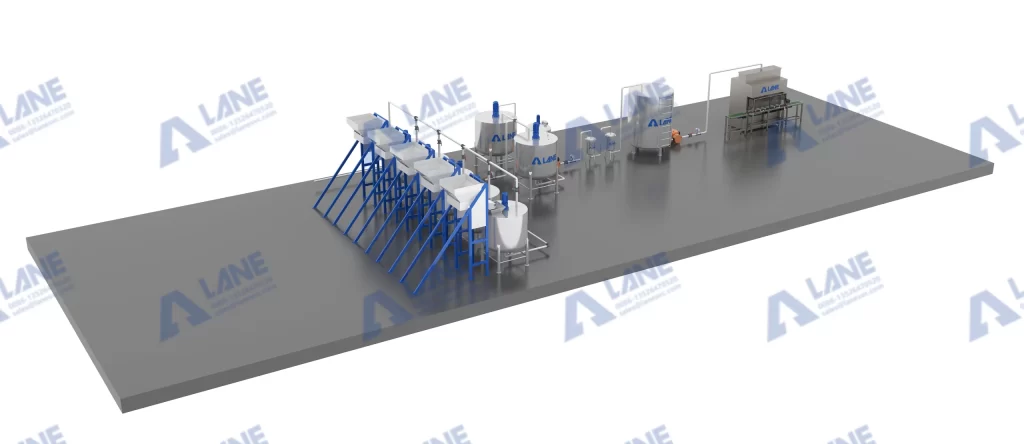

Based on the data given by you, we will do an initial analysis. Our engineers will design a tailored production flow. A standard process for a versatile Liquid Fertilizer for Agriculture line often includes: raw material preparation, precision batching and mixing, reaction/fermentation (for organic inputs), homogenization, filtration, and final packaging.

Fermentation is the logical step for organic liquid fertilizers. In a fermentation tank, microbes break down organic waste with the help of controlled temperature and moisture. For consistent, high-quality blends, a homogenizer is essential. It micronizes particles to prevent settling and ensure uniform nutrient distribution.

Reputable manufacturers like LANE often validate the design through pilot testing. We may run small-scale tests using your actual raw materials to confirm the process yield and final product quality, de-risking the full-scale investment.

Once the process is finalized, manufacturing of the custom equipment begins. The core components of a LANE line change depending on the formulation, but typically include:

LANE Heavy Industry uses corrosion-resistant, industrial-grade materials with a 5-year warranty for core components like PLCs, pressure vessels, and pumps, adhering to international standards such as CE and ISO. All equipment is specifically designed for efficient production of Liquid Fertilizer for Agriculture. We conduct a Factory Acceptance Test (FAT) before shipment, allowing you to witness the Liquid Fertilizer for Agriculture equipment running to ensure it meets agreed specifications.

Upon delivery, our engineers supervise the installation. This stage involves equipment placement, piping, electrical connections, and system integration.

Commissioning is the first run with all systems connected. Engineers fine-tune parameters, troubleshoot initial issues, and run continuous production trials. We make sure the line is working perfectly and meets your quality target.

Our engineers train your technicians and staff on everyday operation, safety protocols, routine maintenance, and basic troubleshooting. This empowers your team for long-term independence.

With commissioning complete, the transition to your operational team begins. The focus shifts to ramping up to full capacity while maintaining strict quality control (QC). QC involves regular testing of parameters like nutrient concentration, pH, density, and stability according to industry standards to ensure the quality of your Liquid Fertilizer for Agriculture.

A strong manufacturing partner provides ongoing support. This usually includes a warranty period, access to spare parts, and remote technical assistance. LANE offers continued support to ensure stable operation of your Liquid Fertilizer for Agriculture production line.

Future-Proofing Your Investment

Choosing a manufacturer that offers modular and scalable solutions is key. As demand grows, you should be able to add capacity or functionality. Furthermore, integrating smart technologies, such as IoT sensors for predictive maintenance and data analytics for process optimization, can enhance efficiency and product consistency over time.

Launching a Liquid Fertilizer for Agriculture production line from pilot to full scale is a systematic process that requires careful planning, rigorous testing, and strategic scaling. It is a multi-stage journey that transforms a strategic vision into a modern farming asset. From the initial feasibility study and pilot testing to the final commissioning and ramp-up, each stage requires planning and expert execution. By collaborating with LANE Heavy Industry, businesses can leverage advanced, customizable machinery to streamline these stages.

Q: What raw materials can I use with a LANE production line?

A: LANE lines are highly adaptable. They can process a wide range of materials for Liquid Fertilizer for Agriculture, from conventional mineral-based nutrients (N, P, K sources) to various organic wastes such as animal manure, food processing residues, biogas slurry, and specifically tested materials like soybean dregs.

Q: How is product quality ensured during production?

A: Quality is built into the Liquid Fertilizer for Agriculture production process through precise PLC-controlled batching, consistent mixing and homogenization, and final filtration. Furthermore, manufacturers like LANE can conduct pilot tests with your specific raw materials before full-scale production to verify the final product meets required standards.

Q: What kind of support can I expect after purchasing the line?

A: Reputable manufacturers provide comprehensive after-sales support. This typically includes on-site installation guidance and commissioning, detailed operator training, a warranty (LANE offers a 5-year warranty), and access to technical support and spare parts to ensure long-term, stable operation of your Liquid Fertilizer for Agriculture production line.

Q: How long does it take to get a production line operational?

A: The timeline varies based on complexity and customization. Equipment manufacturing can take approximately 1-2 months. Including design, shipping, installation, and commissioning, the total project duration from order to full operation typically ranges from 4 to 6 months.

Q: Can the line produce different types of liquid fertilizer?

A: Yes, a well-designed line is often versatile. With adjustable recipes and processes, the same core equipment can usually produce different formulations, such as clear liquid fertilizers, suspension fertilizers, or emulsified foliar fertilizers, by modifying the raw material input and certain process parameters.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Leave a Comment

Latest Posts

LANE has more than 500 successful cases and is committed to providing customers with first-class solutions, high-end machinery and equipment, and one-stop pre-sales, sales and after-sales comprehensive customer service.