Liquid Fertilizer Filling and Packaging Line: Enhancing Efficiency in Fertilizer Production

In modern agriculture, fertilizers are no longer limited to bulk distribution. Precision farming, greenhouse cultivation, and drip irrigation systems demand high-quality liquid fertilizers that are safe, stable, and easy to apply. To meet this demand, manufacturers rely on a liquid fertilizer filling and packaging line, which ensures accuracy, efficiency, and product integrity from production to distribution.

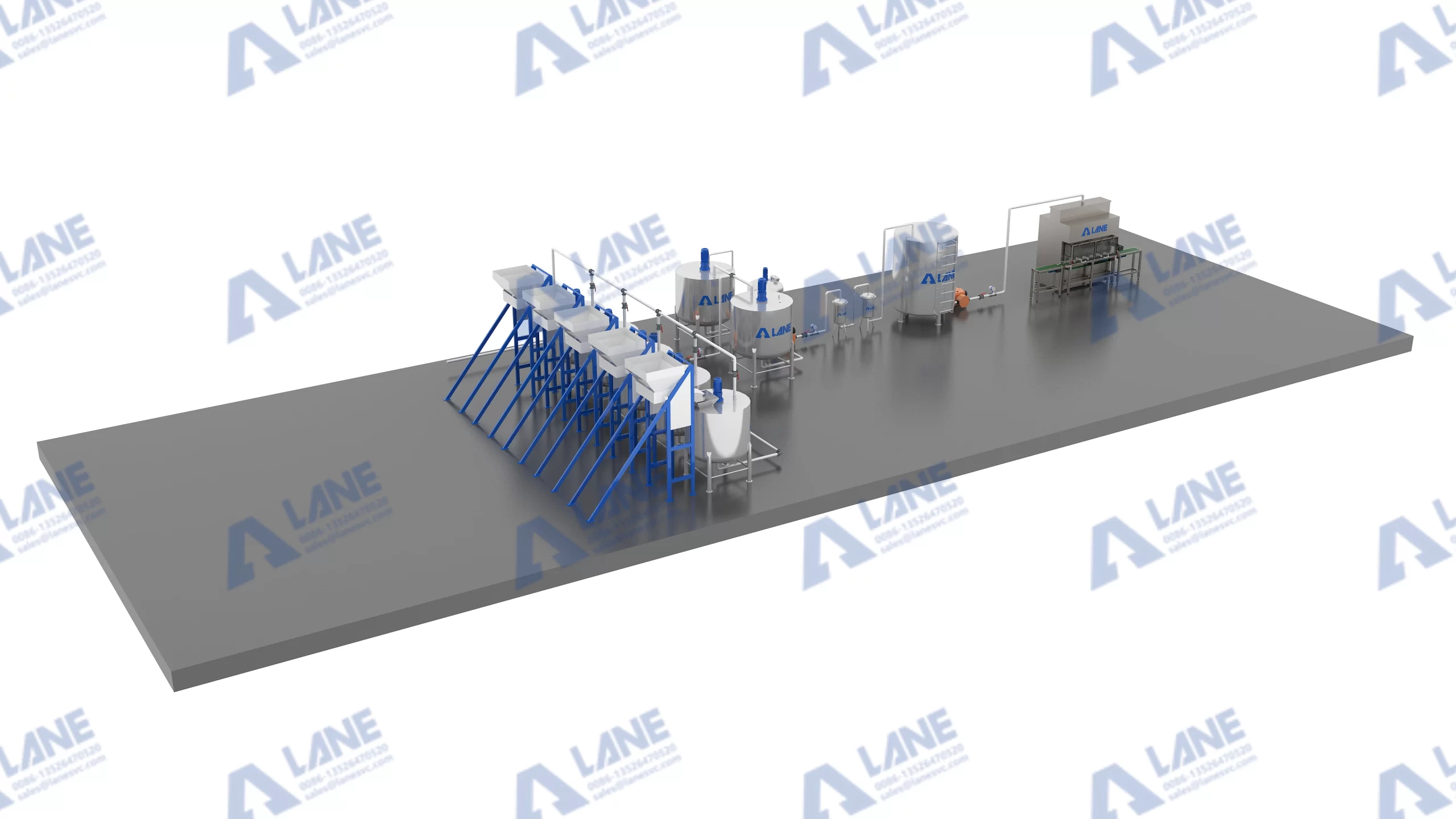

A liquid fertilizer filling and packaging line automates the process of measuring, filling, sealing, and labeling fertilizers in bottles, cans, drums, or intermediate bulk containers (IBCs). By combining reliability with high throughput, it helps producers maintain consistent quality while reducing operational costs.

Accuracy: Guarantees precise dosage in every container, avoiding underfilling or wastage.

Efficiency: Speeds up production to meet market demand.

Safety: Prevents spillage, contamination, and product degradation.

Professional Branding: Well-packaged products gain higher market acceptance.

Flexibility: Handles a wide range of packaging sizes and materials.

The result is a system that not only boosts operational capacity but also strengthens market competitiveness.

Step 1: Feeding and Preparation

Liquid fertilizer is transported from mixing tanks to a storage hopper. Materials are homogenized to prevent precipitation or uneven concentration.

Step 2: Filling Process

Automatic filling machines measure the correct amount of liquid fertilizer before releasing it into containers. Technologies like gravity filling, piston filling, or flowmeter-controlled filling are commonly used.

Step 3: Capping and Sealing

Once filled, containers are sealed using screw caps, press-on caps, or induction sealing machines. This prevents leakage and maintains product quality.

Step 4: Labeling and Coding

Labels are applied automatically, displaying product name, nutrient content, batch number, and production date. Inkjet coding ensures traceability.

Step 5: Secondary Packaging

Individual bottles or containers are grouped into cartons or shrink-wrapped bundles for safe transport.

Step 6: Palletizing and Storage

Automatic palletizers stack cartons neatly, ready for warehouse storage or shipping.

Each step in the liquid fertilizer filling and packaging line is designed to maintain efficiency while ensuring strict quality control.

Stainless Steel Storage Tanks: Preserve fertilizer stability before packaging.

Automatic Filling Machine: Ensures precision and speed during filling.

Capping and Sealing Units: Guarantee leak-proof packaging.

Labeling Machine: Provides branding and regulatory compliance.

Carton Packing Machine: Automates secondary packaging.

Palletizer: Handles large-scale logistics preparation.

This integrated system makes the liquid fertilizer filling and packaging line suitable for both small businesses and large industrial plants.

High Productivity – Supports mass production without compromising accuracy.

Consistency – Delivers uniform packaging quality across all batches.

Cost Reduction – Minimizes labor needs and reduces material waste.

Scalability – Easily adjustable for different fertilizer formulations and container sizes.

Compliance and Traceability – Meets agricultural product regulations with proper labeling and batch coding.

A medium-sized fertilizer manufacturer in Turkey upgraded its manual filling system with an automated liquid fertilizer filling and packaging line. Production capacity increased from 5,000 liters per day to 20,000 liters per day, while labor costs decreased by 40%. The new line also improved packaging consistency, helping the company expand exports to neighboring countries.

A large-scale agribusiness in Brazil producing foliar fertilizers adopted a high-speed liquid fertilizer filling and packaging line to meet growing demand. The system’s flexibility allowed them to package both small bottles for retail and large drums for commercial farms. The automation also reduced spillage and ensured compliance with export regulations.

Viscosity Variations: Some fertilizers are thick and difficult to fill. Solution: Use piston or pump filling technology.

Corrosion Risks: Fertilizer liquids may corrode parts. Solution: Employ stainless steel and anti-corrosion materials.

Initial Investment: High upfront costs deter small producers. Solution: Modular systems allow phased upgrades.

Packaging Diversity: Farmers demand different sizes. Solution: Adjustable filling machines provide flexibility.

The future of liquid fertilizer filling and packaging lines is shaped by automation and sustainability:

Smart Sensors: AI-based monitoring ensures precise filling.

Eco-Friendly Packaging: Shift to recyclable plastics and biodegradable materials.

IoT Integration: Real-time production tracking and quality control.

Flexible Systems: Designed to handle new fertilizer formulations and packaging innovations.

These trends ensure that filling and packaging lines remain central to modern fertilizer production.

A liquid fertilizer filling and packaging line is more than an industrial setup—it is a strategic investment in efficiency, safety, and product quality. By ensuring accurate dosage, secure packaging, and professional branding, it empowers fertilizer producers to meet rising agricultural demands.

From Turkey to Brazil, real-world examples show that adopting a liquid fertilizer filling and packaging line enhances competitiveness and reduces costs. As agriculture continues its shift toward precision and sustainability, such systems will remain indispensable in bridging the gap between production and farmers’ needs.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Leave a Comment

LANE has more than 500 successful cases and is committed to providing customers with first-class solutions, high-end machinery and equipment, and one-stop pre-sales, sales and after-sales comprehensive customer service.