Precision by Design: The Role of Automation in Modern Liquid Fertilizer Export Production Line

Table of Contents

In the global market for agricultural fertilizer, consistency, quality, and efficiency are key to gaining customer trust. The liquid fertilizer export market has significant global opportunities, but a modern liquid fertilizer export production line needs to meet the quality standards of different countries and regions while maintaining high productivity, stable operation, and strict cost control.

For fertilizer manufacturers that want to target international customers, there is no other option than a fully automated liquid fertilizer export production line. Export markets demand strict adherence to formulation accuracy, impeccable quality control, and traceability from raw material to final packaging.

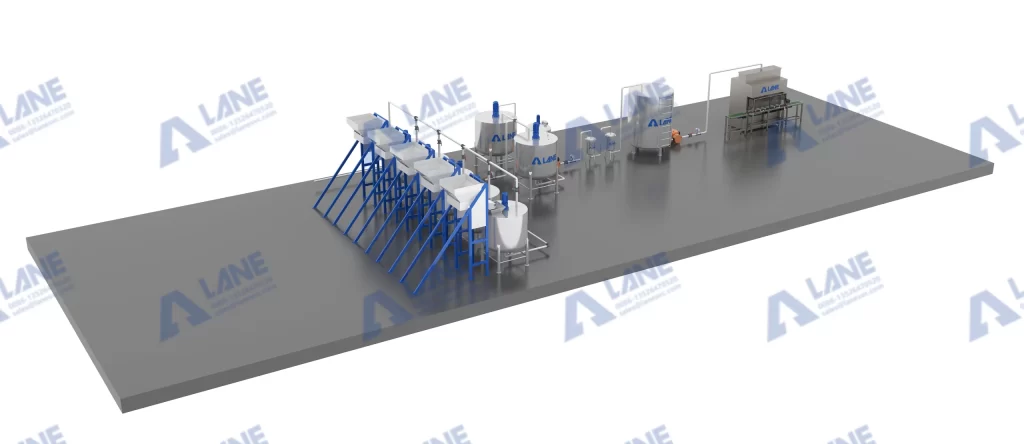

LANE Heavy Industry, a leader in the fertilizer machinery manufacturing industry, provides the solution for this with their production line design and manufacturing capability. We create automation and control systems that transform a production facility from a cost center into a strategic, reliable, and highly competitive asset.

An automated control system for a liquid fertilizer export production line is a network of hardware and software that manages, monitors, and documents the entire manufacturing process with minimal human intervention. It replaces manual operations such as valve operation, batch weighing guesswork, and paper-based logging.

This system ensures that every drop of fertilizer produced meets the chemical specifications and is homogeneous. Every step is recorded for analysis and compliance. It coordinates all components of the line into a single, efficient organism.

A modern automated line integrates several key subsystems:

As a leading turnkey provider, LANE Heavy Industry designs, manufactures machinery, and trains technicians to ensure the production line works perfectly from day one. Our philosophy is to deliver a complete, operational, and optimized liquid fertilizer export production line.

Investing in a fully automated liquid fertilizer export production line with LANE delivers significant returns:

The automation and control system has become the cornerstone of success in the premium fertilizer export market. In today’s landscape, quality is defined by data and repeatability. LANE Heavy Industry, as a reliable turnkey provider, integrates advanced technology and practical experience into its automation solutions.

Q1: How does automation specifically help with the “export” part of a liquid fertilizer production line?

Automation ensures compliance with international standards by providing unalterable digital records (traceability), guaranteeing batch-to-batch consistency, and enabling precise formulation adjustments for different market requirements.

Q2: Is a fully automated line only feasible for large-scale producers?

Not at all. While large-scale operations bring greater ROI, LANE Heavy Industry designs scalable solutions. We offer modular automation packages that can start with core process automation (dosing, mixing) for small to mid-size exporters. The production line can be scaled up when the business grows.

Q3: What is the typical ROI period for automating an existing production line?

The return on investment depends on the operation scale and production volume. Normally, customers see ROI within 1.5 to 3 years through quantifiable savings in raw material waste, reduced labor costs, and lower quality rejection rates.

Q4: As a turnkey provider, what does LANE Heavy Industry deliver exactly?

LANE delivers a complete, ready-to-operate facility. This includes: process design & engineering, supply of all mechanical equipment (reactors, tanks, piping), supply and programming of all automation hardware (PLCs, sensors) and software (SCADA), installation supervision, and operator training. We provide a single-point solution for the entire liquid fertilizer export production line.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Leave a Comment

Latest Posts

LANE has more than 500 successful cases and is committed to providing customers with first-class solutions, high-end machinery and equipment, and one-stop pre-sales, sales and after-sales comprehensive customer service.