Liquid Fertilizer Equipment for Southeast Asia: Driving Sustainable Agriculture Growth

In recent years, liquid fertilizer equipment for Southeast Asia has gained significant attention as farmers and agricultural enterprises seek efficient, sustainable, and cost-effective fertilization solutions. With the region’s rapidly developing agriculture sectors in countries such as Indonesia, Thailand, Vietnam, Malaysia, and the Philippines, liquid fertilizers have become an ideal choice to improve soil fertility, increase crop yields, and enhance sustainable food production.

This article explores the growing demand for liquid fertilizers in Southeast Asia, the key equipment used in production, and how professional suppliers like LANE Heavy Industry are helping agricultural businesses establish high-quality liquid fertilizer production lines in the region.

Southeast Asia is one of the world’s most dynamic agricultural regions, producing rice, palm oil, corn, coffee, sugarcane, fruits, and vegetables in massive quantities. However, the region also faces challenges such as soil degradation, nutrient depletion, and the need for sustainable farming practices. Liquid fertilizer equipment for Southeast Asia has a large market.

Farmers are increasingly turning to liquid fertilizers because of their many advantages:

Fast Nutrient Absorption: Liquid fertilizers can be easily absorbed by plant roots and leaves.

Customizable Formulations: Nutrients can be adjusted according to crop type and soil condition.

Ease of Application: Suitable for use in drip irrigation, foliar spraying, and hydroponics systems.

Eco-Friendly: Often made from organic waste materials, reducing pollution and improving soil structure.

As a result, liquid fertilizer equipment for Southeast Asia is becoming a high-demand investment among agribusinesses, cooperatives, and fertilizer manufacturers.

In Southeast Asia, abundant organic waste provides an ideal foundation for liquid fertilizer manufacturing. Common raw materials include:

Animal manure (from poultry, cattle, or pigs)

Crop residues and straw

Fruit and vegetable waste from food processing industries

Sugarcane bagasse and palm oil residues

Fish waste or seaweed extract for high-value organic formulations

These locally available resources help reduce production costs while promoting environmental sustainability.

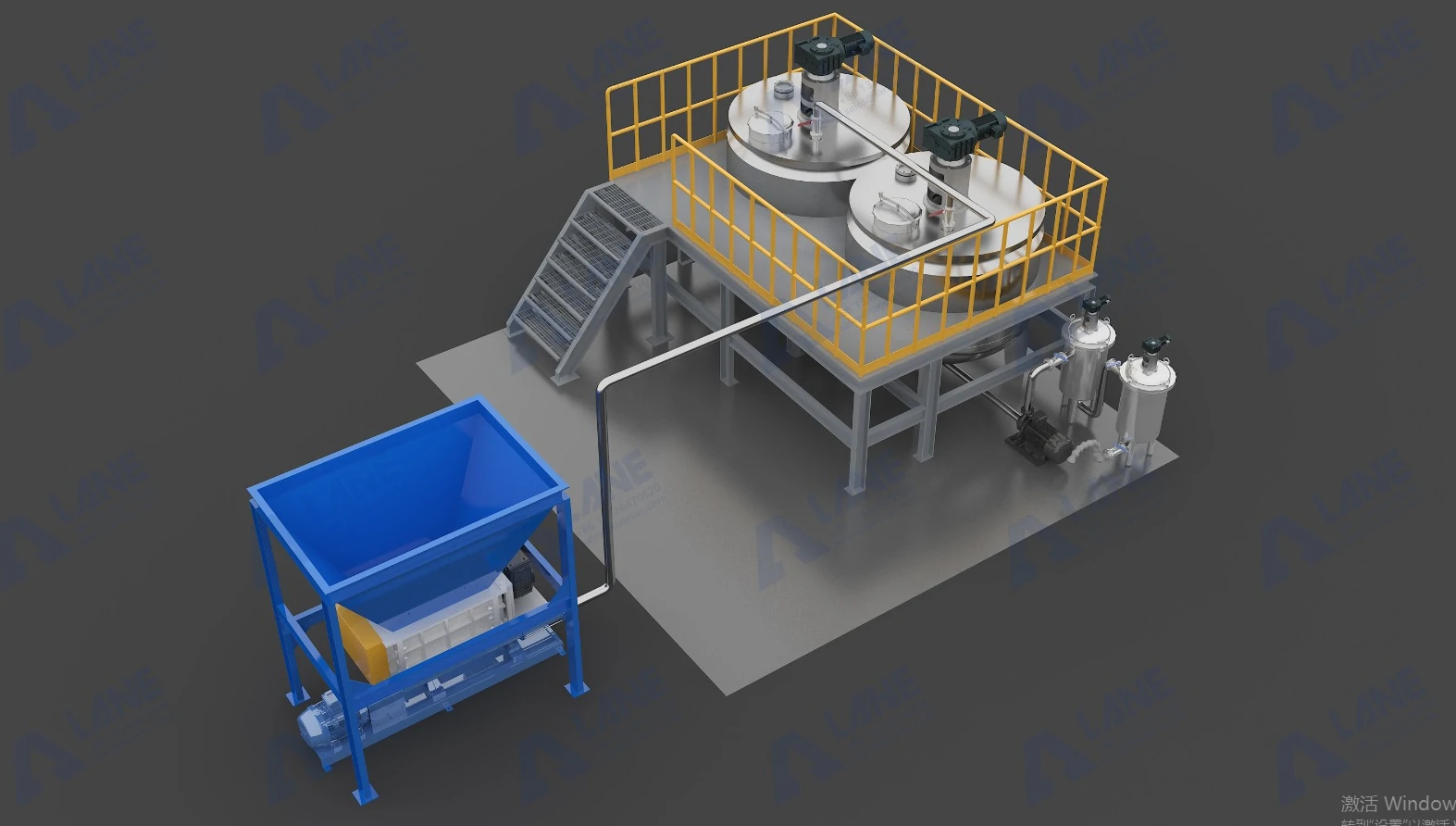

Establishing a liquid fertilizer production line involves several well-coordinated steps — from raw material fermentation to filtration and packaging. Below is an overview of the production flow and the essential liquid fertilizer equipment for Southeast Asia.

Raw Material Crushing and Mixing

Before fermentation, raw materials need to be crushed and mixed to ensure uniform particle size and nutrient balance.

Equipment Used:

Vertical Crusher – Crushes raw materials into fine particles.

Horizontal Mixer – Ensures even distribution of nutrients and moisture.

Fermentation Process

Fermentation is the most important step in producing high-quality liquid fertilizer. During this process, microorganisms decompose organic matter and release plant-available nutrients.

Equipment Used:

Fermentation Tank (Bioreactor): Stainless steel or carbon steel tanks designed for aerobic or anaerobic fermentation.

Compost Turner Machine: For larger-scale open-air fermentation, crawler-type compost turners or wheel compost turners are used to aerate and mix materials, maintaining ideal oxygen and temperature conditions.

Fermentation typically lasts 7–15 days, depending on temperature, humidity, and material composition.

Filtration and Separation

After fermentation, the mixture contains both solid and liquid components. The liquid portion is separated and filtered to remove impurities.

Equipment Used:

Solid-Liquid Separator: Removes solid residues from the liquid fertilizer.

Filter Press or Centrifuge: Further refines the liquid for clarity and purity.

This ensures that the liquid fertilizer is smooth, uniform, and free of suspended particles — suitable for spraying or irrigation systems.

Nutrient Enrichment and Formulation

At this stage, nutrients such as humic acid, amino acids, trace minerals, or seaweed extract can be added to enhance the fertilizer’s nutrient profile.

Equipment Used:

Stainless Steel Mixing Tank: Combines additives evenly into the liquid fertilizer.

Agitator or Stirring Device: Maintains uniformity during mixing and prevents sedimentation.

LANE’s automatic dosing and mixing systems can precisely control nutrient ratios, ensuring consistency and high product quality.

Storage and Packaging

The final liquid fertilizer is stored and packaged for sale or distribution.

Equipment Used:

Storage Tanks: Stainless steel storage tanks prevent contamination and maintain product stability.

Filling Machine: Automatically fills bottles, drums, or containers with the liquid fertilizer.

Capping and Labeling Machines: Complete the packaging process, preparing the product for market distribution.

As a professional manufacturer of fertilizer machinery, LANE Heavy Industry provides complete liquid fertilizer production solutions for Southeast Asian clients.

Key Advantages about Liquid Fertilizer Equipment for Southeast Asia:

✅ Turnkey Solutions: From raw material processing to packaging — a complete production line design.

✅ Customizable Capacity: Equipment tailored to different scales — from 1 ton/hour to 10 tons/hour.

✅ Energy Efficient: Low energy consumption with high output.

✅ After-Sales Support: LANE provides installation, technical training, and long-term maintenance.

Many successful installations across Indonesia, Vietnam, and Malaysia have proven the reliability of LANE’s fertilizer machinery.

The agricultural modernization of Southeast Asia has created a promising future for liquid fertilizer production. With supportive government policies promoting organic and sustainable farming, the demand for liquid fertilizer equipment for Southeast Asia is expected to grow rapidly.

The region’s tropical climate also supports year-round crop cycles, creating continuous fertilizer demand. Establishing a local liquid fertilizer production line helps reduce import dependence and transportation costs while supporting the development of eco-friendly agriculture. Liquid fertilizer equipment for Southeast Asia has considerable demand.

The rise of liquid fertilizer equipment for Southeast Asia represents a major step toward sustainable agricultural transformation. By turning organic waste into valuable fertilizer, local producers can not only enhance soil fertility and crop productivity but also contribute to environmental protection and circular economy development.

With reliable suppliers like Ryan Heavy Industry, farmers and agricultural enterprises across Southeast Asia can easily establish efficient and cost-effective liquid fertilizer production lines – injecting impetus into the green agricultural development of the region. We are more than willing to provide liquid fertilizer equipment for Southeast Asia.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Leave a Comment

Latest Posts

LANE has more than 500 successful cases and is committed to providing customers with first-class solutions, high-end machinery and equipment, and one-stop pre-sales, sales and after-sales comprehensive customer service.