Liquid Fertilizer Blending Production Line for Your Business? | LANE Heavy Industry Guide

The agriculture industry is shifting toward high efficiency and customized fertilization solutions. Growers are moving beyond one-size-fits-all solutions. They are now interested in precision agriculture with customized nutrient formulations tailored to specific crops, soil conditions, and growth stages. This creates an opportunity for entrepreneurs and agribusinesses to create their own large-scale fertilizer operations. A liquid fertilizer blending production line is one such opportunity.

Liquid fertilizers are very popular for their quick absorption rate and high nutrient utilization rate (up to 90%, far exceeding traditional granular fertilizers). Investing in a high-quality liquid fertilizer blending production line can reshape your operational efficiency and market competitiveness.

This article focuses on LANE Heavy Industry’s liquid fertilizer blending production line, exploring its benefits, key considerations, and advantages.

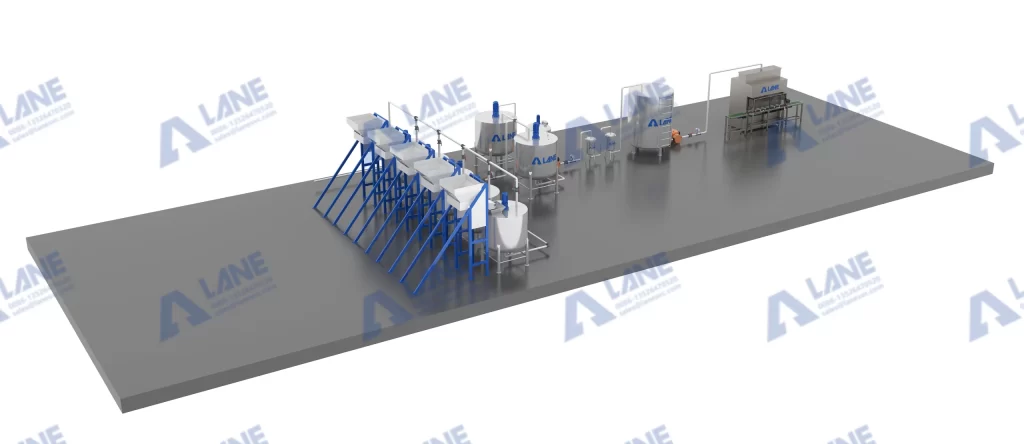

A liquid fertilizer blending production line is a system designed to accurately mix chemical raw materials into uniform, stable, and market-ready liquid fertilizer. Some of the raw materials for generic liquid fertilizers are nitrogen concentrates (UAN), phosphoric acid, potassium sources, micronutrients, and additives. It is more than a mixing tank. A complete line from LANE Heavy Industry includes:

This integrated approach transforms raw materials into high-value premium liquid fertilizer.

A liquid fertilizer blending production line has several benefits that give you an advantage.

You have to evaluate yourself and your surroundings before you start your liquid fertilizer production.

If you answered “Yes” to several of these, then a liquid fertilizer blending production line is a strong consideration.

Choosing the right partner for your liquid fertilizer blending production line is a critical decision. LANE Heavy Industry provides more than machinery; we deliver fully customizable engineered solutions.

A liquid fertilizer blending production line is a valuable investment for businesses aiming to capitalize on the growing demand for high-efficiency liquid fertilizers. Adding one is a significant capital investment with powerful potential returns. It is the right starting point for businesses that are ready to evolve from distributors to solution providers.

Partnering with an experienced engineer like LANE Heavy Industry early in this process is invaluable. We can provide layout recommendations, capacity planning, and detailed equipment specifications to turn your vision into a precise, profitable reality.

Q1: What is the typical lead time and investment range for a LANE blending line?

A1: Lead times vary based on complexity, typically from 3 to 6 months from order to shipment. Investment ranges significantly with capacity and automation level, from mid-six figures for a semi-automatic batch system to higher investments for fully automated, high-capacity continuous lines. LANE provides detailed quotations after a thorough needs assessment.

Q2: Can you handle the entire project, including plant layout and installation?

A2: Yes. LANE Heavy Industry specializes in turnkey projects. Our team can design the plant layout, manufacture all core components, provide electrical and piping schematics, supervise installation, and commission the complete liquid fertilizer blending production line, including operator training.

Q3: How do you ensure the blends are uniform and the ratios are accurate?

A3: Precision is engineered into our systems. We utilize high-accuracy mass flow meters or calibrated piston-dosing pumps for each raw material, controlled by a programmable logic controller (PLC). This ensures every batch matches the digital recipe exactly, providing consistent product quality.

Q4: What materials are used to combat corrosion from fertilizers?

A4: We select materials based on the specific chemicals processed. This often includes 316/304 stainless steel for certain solutions, fiberglass-reinforced plastic (FRP) for high-corrosion areas, and specialized coatings or alloys for critical components, ensuring durability and product integrity.

Q5: Can the system produce suspensions as well as clear liquid blends?

A5: Absolutely. LANE designs specific liquid fertilizer blending production lines for suspension fertilizers. These systems include high-shear mixers and in-line homogenizers to keep solid particles in suspension, along with specialized tanks with agitators to prevent settling during storage.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Leave a Comment

LANE has more than 500 successful cases and is committed to providing customers with first-class solutions, high-end machinery and equipment, and one-stop pre-sales, sales and after-sales comprehensive customer service.