How a Liquid Fertilizer Batch Production Line Works: A Step-by-Step Guide

Liquid fertilizer is very popular among agricultural businesses and entrepreneurs because of its fast nutrient absorption, high utilization rate, and easy application. For farmers and entrepreneurs looking to start producing their own consistent, high-quality fertilizers, understanding the mechanics of a liquid fertilizer batch production line is the first critical step.

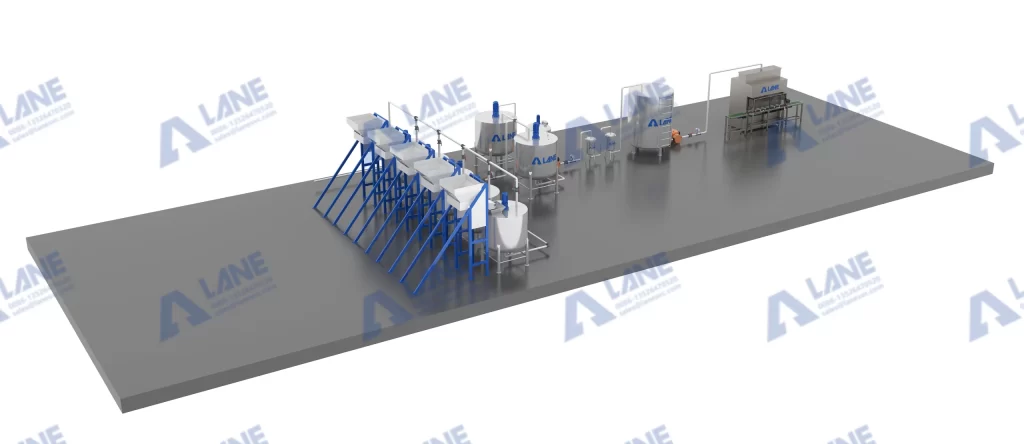

A liquid fertilizer batch production line is a systematic equipment combination that ensures precise ingredient blending, stable quality, and scalable output. It creates a single, controlled volume of product from start to finish before beginning the next. This method gives precise control over recipes and quality, and is ideal for producing specialized blends.

LANE Heavy Industry Co., Ltd., a leading provider of fertilizer equipment, has optimized this complex process for streamlined and reliable operations. This article breaks down the process step by step and explains how LANE production lines streamline the entire operation.

A liquid fertilizer batch production line operates on a cyclical “make-one-batch-at-a-time” principle. This allows operators to make precise formulation adjustments between batches. This makes it perfect for producing different NPK grades, adding micronutrients, or creating custom blends for specific crops.

The entire process revolves around a central mixing tank, supported by a system for raw material handling, precise dosing, controlled mixing, storage, and final packaging.

Step 1: Raw Material Intake & Storage

The first step in the batch production process is raw material pretreatment, a critical stage to eliminate impurities and ensure ingredient uniformity. The process begins with the storage of raw materials. These typically include:

Base Solutions: The base solutions depend on the formulation. Some of them are ammonium nitrate, urea ammonium nitrate (UAN), phosphoric acid, and potassium chloride solutions.

Water: Often demineralized to prevent unwanted chemical reactions. Purified water is the preferred choice for a liquid fertilizer batch production line.

Additives: Micronutrients, stabilizers, wetting agents, or corrosion inhibitors. They work as supplements for the formulation and some of them make the product have a longer shelf life.

A liquid fertilizer batch production line designed by LANE has dedicated space for those raw materials. They are stored in dedicated, often corrosion-resistant tanks. They are transported by pumps and pipes. They take each material to the dosing station. Proper storage and segregation are important to prevent cross-contamination.

Step 2: Precision Dosing & Weighing

This system determines the product consistency. Based on the specific fertilizer recipe, exact quantities of each raw material must be delivered to the raw material mixer.

LANE’s Role: LANE’s designed Dynamic Batching system eliminates manual measurement errors. It can be centrally controlled by PLC. LANE Machinery integrates high-accuracy sensors and controls to ensure each batch matches the formula exactly.

Step 3: The Mixing & Reaction Phase

Once all the raw materials are in the raw material mixing tank, the controlled mixing process begins.

The Mixer: LANE’s raw material and main mixing tank is more than just a container; it is a reactor equipped with a powerful, purpose-designed agitator. This agitator creates a homogeneous mixture. This ensures even distribution of all nutrients.

Process Control: LANE mixers are equipped with sensors that can detect liquid pH and temperature. The operator can detect any changes in the liquid solution and adjust the formulation. The mixing speed can also be adjusted. A specific reaction time or temperature profile is necessary for proper chelation or stabilization of nutrients.

Step 4: Quality Control & Adjustment

After the main mixing process, a sample is taken for quality testing. This checks for density, pH, or nutrient concentration.

The Advantage of Batch Processing: If adjustments are needed, additional materials can be easily dosed into the same batch before it is finalized. This is a key benefit of a liquid fertilizer batch production line, guaranteeing that every batch meets strict quality standards before it moves to packaging.

Step 5: Filtration & Final Polishing

The homogeneous mixture is then pumped through a filtration system. LANE’s dual filter is used in this step. It has double chambers and runs continuously. This step removes any undissolved solids or incidental impurities that could clog application equipment in the field.

A polished, clear liquid demands a higher premium price. It is essential for professional-grade products and customer satisfaction.

Step 6: Storage & Packaging

The finished batch is transferred to a clean storage tank before packaging. LANE’s stainless steel storage tanks act as holding tanks and are equipped with agitators. This prevents the liquid fertilizer from settling. From here, the liquid fertilizer batch production line automates the filling process into various containers.

Step 7: Clean-in-Place (CIP)

The most defining feature of a LANE liquid fertilizer batch production line is the Clean-in-Place (CIP) system. After a batch is completed, the main mixing reactors along with all the equipment can be flushed and cleaned with water or cleaning solutions without disassembly. This prevents cross-contamination between different fertilizer batches.

Investing in a turnkey liquid fertilizer batch production line from LANE Machinery transforms this multi-step process into a smooth, efficient operation.

Cohesive Design: All components of the liquid fertilizer batch production line, from storage tanks and dosing pumps to the reactor and packaging, are designed and manufactured by LANE to work together seamlessly.

Automation: A central control system manages the entire batch system with a PLC. This reduces labor cost and human error.

Scalability: Production lines designed by LANE are scalable. You don’t need to remove or throw away any equipment when you upgrade your production line. You can add automation or capacity when you choose.

Safety & Durability: Equipment is built with SS304 or SS316 steel. They can handle corrosive raw materials. LANE equipment includes safety interlocks and ventilation systems.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Leave a Comment

Latest Posts

LANE has more than 500 successful cases and is committed to providing customers with first-class solutions, high-end machinery and equipment, and one-stop pre-sales, sales and after-sales comprehensive customer service.