Liquid Biofertilizer Production Technology: From Manure to Microbial Gold

For modern, sustainable agriculture, adopting liquid biofertilizer production technology is a smart shift. This method transforms manure into microbe-rich, nutrient-balanced solutions that feed soil life and boost plant growth. From startup farms to large cooperatives, understanding how this technology works—and why the right equipment matters—can open doors to healthier yields and eco-positive operations.

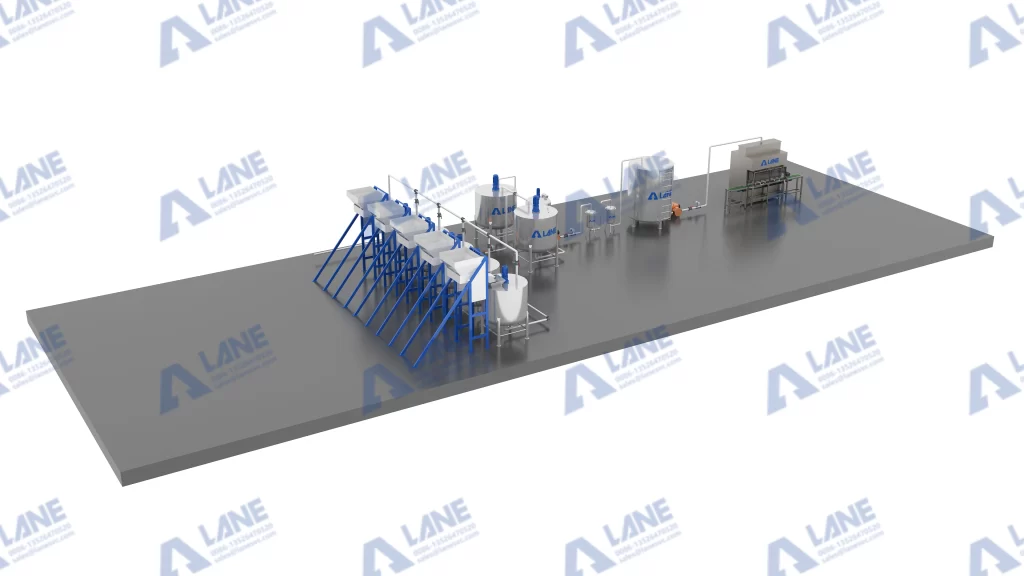

Unlike simple nutrient-based formulas, liquid biological fertilizers combine beneficial microorganisms with organic nutrients to achieve dual effects. To ensure efficient production, the liquid biofertilizer production technology follows a clear process: separating solids, filtering impurities, killing pathogens, anaerobic fermentation, and finally packaging the finished product.

1.Separating Liquids from Solid Animal Manure

First, raw manure (from poultry, cattle, or pigs) is fed into a decanter centrifuge or solid-liquid separator. This crucial step separates the liquid fraction—which contains nutrients and microbes—from solids used for compost or soil amendment.

2.Filtering Impurities from Manure Liquids

The separated manure liquid then passes through a dual filter to remove suspended fibers, sand, or grit. LANE’s precision filtration unit ensures clean feedstock for fermentation, preventing clogs and ensuring consistency.

3.Sterilization of Pathogens in Manure Liquid

To eliminate harmful bacteria and pathogens, the filtered liquid is treated in a heat exchanger or UV sterilizer. This step ensures safe microbial balance while preserving beneficial organisms crucial for biofertilizer efficacy.

4.Anaerobic Fermentation for Bio-Organic Liquid Fertilizer

With sterilized base, the fluid moves into sealed anaerobic fermenters where specific microbial cultures (e.g., Bacillus, Trichoderma, or Azospirillum) are introduced. Over several days, these microbes consume organic compounds and multiply, creating a rich, bioactive fertilizer. LANE’s vertical fermentation tanks maintain precise conditions—temperature, pH, and agitation—to ensure consistency.

5.Packing Liquid Organic Biofertilizer

Once fermentation is complete, the liquid biofertilizer is transferred to automatic filling machines. These provide clean, scalable packaging—ranging from small retail bottles to bulk containers—ready for use or sale.

Earlier this year, I had a conversation with a long-time customer in northern Thailand. His farm, which raises around 300 pigs, had been struggling with manure management and rising costs of synthetic fertilizer. He decided to invest in a small-scale liquid biofertilizer production line, sourced from LANE.

With LANE’s support, he installed a solid-liquid separator, UV sterilizer, and a compact fermenter system. What impressed him most was the plug-and-play design—easy to operate, minimal labor, and low energy consumption.

Within two months, he was not only fertilizing his own rice paddies but also bottling surplus liquid biofertilizer for sale at the local market. “It’s not just fertilizer anymore,” he said. “It’s an opportunity.” What began as a waste solution turned into a profitable micro-enterprise—cleaner operations, better crops, and extra income.

LANE’s liquid biofertilizer production technology is more than just a set of machines—it’s an integrated system designed to deliver performance, efficiency, and long-term value. What sets LANE apart is the attention to every detail in the workflow: from separating solids and filtering manure liquids to precision-controlled anaerobic fermentation and hygienic packing.

Our systems are engineered to retain the highest levels of beneficial microbial activity, amino acids, and plant-available nutrients. We use stainless steel reactors, fully automated control panels, and modular designs that scale from 500 liters/day up to 50,000 liters/day.

Clients particularly value:

Energy Efficiency: Motors and pumps optimized for low power consumption.

Low Odor Emissions: Enclosed systems with odor control options.

Compliance Ready: Output meets organic certification standards in multiple countries.

Service Assurance: Remote diagnostics, installation support, and customized training packages.

Whether you’re a smallholder cooperative or an industrial agri-processor, LANE provides more than machinery—we provide a pathway to sustainable growth.

The demand for liquid biofertilizer production technology spans across a wide range of farming systems, and LANE’s solutions have been tailored to meet these varying needs.

Organic Crop Farms: Biofertilizers produced with LANE’s system enrich the soil microbiome, improve nutrient uptake, and comply with organic farming standards.

Livestock Operations: Pig, cattle, and poultry farms use our technology to upcycle animal waste into value-added fertilizers, solving both environmental and economic problems.

Agro-Industrial Parks: In larger-scale integrated farming or agricultural processing zones, LANE systems serve as central fertilizer hubs, supporting surrounding farms with consistent, high-quality output.

Government Projects & NGOs: Our systems are often adopted in rural development projects and sustainable agriculture programs across Southeast Asia, Africa, and Eastern Europe.

Each deployment is customized based on local manure composition, climate conditions, and target crops—ensuring that the biofertilizer is not only effective, but also adapted for real-world success.

Liquid biofertilizer production technology bridges waste management and soil health—turning problems into productivity. The key lies in equipment that handles each process step meticulously, and that’s where LANE excels: designing efficient, scalable systems backed by technical support. Cultivate with confidence, grow with purpose, and harvest results that matter—for your crops, your business, and the planet.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Leave a Comment

LANE has more than 500 successful cases and is committed to providing customers with first-class solutions, high-end machinery and equipment, and one-stop pre-sales, sales and after-sales comprehensive customer service.