Liquid Biofertilizer Production Line Processes and Advantages

Heavy agricultural productivity comes with the cost of soil degradation and environmental pollution cause by the chemical fertilizers. Which slowly makes the land unfertilized and reduces the corp yields. To combat this problem government and farmers are turning towered environmental friendly new economical alternatives. Farmers are searching for fertilizer that can not only help increase their crop yeild but also enhance the soil fertility. Liquid biofertilizer production line solves this problem.

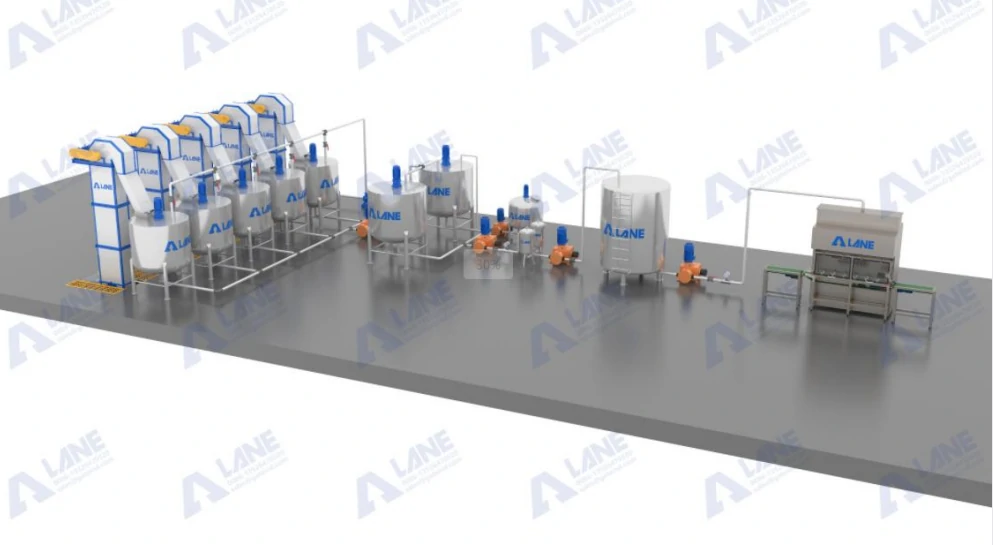

Liquid biofertilizer contains living microorganisms that can increase plant growth by supplying them with nutrition. This fertilizer enhance soil health, improve nutrient uptake, and reduce the dependence on synthetic fertilizers. To fill the need of increased demand LANE heavy industry have developed the LANE liquid biofertilizer production line—a fully automated system designed for efficiant and consistent production.

This article provides a full overview of the liquid biofertilizer production line, including its raw materials, processing steps and equipements.

Liquid bio fertilizers are microbiological-based products which are formulated in a liquid medium that supports the survival and activity of beneficial microorganisms. Unlike chamical fertilizer , which provide immediate but short-term nutrient boosts, liquid fertilizer keeps soils biological balance. It stimulate root development, enhance seed germination, and increase resistance against diseases and environmental stress.

The production of liquid biofertilizer depends on nutrient-rich and biodegradable raw materials that support microbial growth and activity. The most commonly used materials include:

Biogas Liquid:

this is by-product of biogas plants. organic matter, nitrogen, and trace elements. It acts as an excellent base medium.

Livestock and Poultry Wastewater:

This is the most available source of raw material. This is rich in nitrogen, phosphorus, potassium, and organic carbon. It provides a valuable underlayer for microbial growth.

Pharmaceutical Process Waste:

Some of the by-products from the pharmaceutical can be recycled to provide amino acids and organic nutrients for the biofertilizer.

Amino Acid Residues:

Amino acid can be found on wasted material from food and feed industries. Amino acid residues improve microbial metabolism.

Macronutrients:

Essential elements like Nitrogen (N), Phosphorus (P), and Potassium (K) are included in to balance the proportions to support plant.

Secondary Nutrients:

Elements such as Calcium (Ca), Magnesium (Mg), and Sulfur (S) strengthen plant cell walls and enzyme functions.

Micronutrients:

Trace minerals such as Iron (Fe), Zinc (Zn), Copper (Cu), and Manganese (Mn) are vital for enzymatic activity and plant metabolism.

By combing those materials, the LANE Liquid biofertilizer production line makes fettilizer is rich in organic matter, beneficial microbes, and plant nutrients.

The LANE liquid biofertilizer production line follows a automated, continuous workflow. This process includes several critical stages. Each stage is designed for efficiency, consistency and quality. Controlled by the PLC.

Raw Material Feeder

Raw materials are put into the LANE elevetor feeder. The feeders The feeder ensures controlled input of substrates such as biogas liquid and amino acid residues. Precision feeding makes sure the feeds are put in to the mixer as precisely as intended.

Raw Material Mixing Tank

The primary raw materials are first put into the mixing tank for blending. Where they achieve uniform blending. This step ensures proper homogenization of organic matter, nutrients, and water. The mixing tank is equipped with an agitator, temperature control system, and pH monitoring system to maintain optimal conditions for microbial survival. Operator can control the mixing machine from control room. Making it easy and safe to use.

Mixing Tank (Main Fermentation Unit)

When the blending is done all the materials are transferred to the main mixing or fermentation tank. In here operator can add beneficial bacteria to the fertilizer blends to make the fertilizer strong. The environment inside the fermentation tank is closely monitored. The temperature and PH level are carefully regulated to encourage microbial activity.

In the LANE liquid biofertilizer production line, fermentation takes several hours from days depending on the formula of the fertilizer, During this time, microorganisms multiply and convert organic materials into forms that are easily absorbed by plants.

Oxygen supply is necessary for this steps. LANE mixing tank is equipped with aeration and agitation system which properly transfer oxygen and promotes aerobic microbial activity.

Additive Mixing Tank

After fermentation, the operator can added extra raw materials according to their formulation. It can be of stabilizers, nutrients, or growth-promoting compounds to enhance shelf life and effectiveness. The additive mixing tank allows controlled mixing of micro nutrients, amino acids and protective agents.

This ensures that the final formulation maintains microbial activity even during storage and transportation.

The LANE duplex filter removes any removes impurities, solid residues, and unwanted particles from the liquid biofertilizer production line. This ensures a smooth, clog-free product suitable for liquid application systems. The duplex filter setup allows continuous operation—while one filter is in use, the other can be cleaned or replaced, minimizing downtime.

The filtered liquid biofertilizer then moved into the LANE storage tank. Here the liquid biofertilizer stabilizes itself. These tanks are designed to maintain stable conditions, preventing microbial contamination or nutrient degradation. The tanks are equipped with temperature control system.

Automated Filling Machine

The final step of the liquid biofertilizer production line is packing. The LANE packing machine can fill bottles, cans, or containers using an automated filling. This limits the human contact and make it hygienic and fast.

The packaged products are then ready for quality testing, distribution, and sale

The liquid biofertilizer production line utilizes organic waste materials to create microbiological activity. Which is an environmentally friendly process. Chemical fertilizers releases greenhouse gas and consumes non-renewable resources. The liquid biofertilizer production line turns environmental pollutants into valuable agricultural inputs.

Efficient Nutrient Utilization

The mirobiological activity caused by the liquid fertilizer stays active long time after application. It improve the efficiency of nutrients uptake by plants. It keeps improving the soil and root of the plants enhancing nutrient cycling in the soil long after application.

Cost-Effective and Sustainable

The raw material for liquid biofertilizer production line are sustainable resources. It is low in cost and sometime those can be acquired free of charge. This significantly reduces production costs.

Enhanced Microbial Viability

The controlled environment of the LANE production line ensures that beneficial microorganisms remain active , leading to better fertilizer performance and longer shelf life of the product.

Automation and Quality Control

Automation minimizes human error and contamination, ensuring consistent quality. Sensors and control systems maintain precise distribution throughout the process, from mixing to packaging.

Customizable Formulations

Producers can easily change or adjust the formulation by modifying the material and adding specific microbial strains according according to specific crop.

Reduced Pollution and Waste

The raw material often includes waste streams such as livestock wastewater or pharmaceutical residues. By removing them from environment the liquid biofertilizer production line is helping protecting the earth and achiving the green economy dream.

While solid biofertilizers and chemical fertilizers have been widely used for decades, liquid biofertilizer production lines offer distinct advantages:

Higher Microbial Efficiency:

Microbiological activity in the liquid form remain more active then those in powdered or granauler forms, resulting in faster and more effective plant responses

Ease of Application:

Liquid biofertilizers can be applied through irrigation systems, foliar spraying, or seed treatment. It offers more flexibility then the tradidional granuler fertilizers.

Faster Nutrient Absorption:

plants adsorb liquid faster then the granuals. This makes more faster nutrition intake and this process gets batter results.

Uniform Distribution:

The liquid form ensures even distribution of nutrients and microbes across the field. Making the crop performance consistence throuout the field.

Lower Production Energy Requirement:

Chemical fertilizer require high-temperature reaction for mixing different raw materials. liquid biofertilizer production operates under mild, biological conditions. It doesn’t requires high temperature, which makes it energy saving.

Improved Soil Health:

Continuous use of chemical fertilizers depletes organic matter and beneficial microorganism. Liquid biofertilizers restore the microbiological activity and organic balance of the soil

Versatility and Adaptability:

The production line can utilize various waste sources as raw materials, adapting to regional availability and environmental regulations. Government around the world welcomes the liquid Liquid biofertilizers production line, making permit easy to acquire.

Conclusion

The LANE Liquid Biofertilizer Production Line represents the next generation of sustainable fertilizer manufacturing. This production line combine modern engineering and biotechnology to transform organic waste into a valuable fertilizer. From feeding , mixing, fermenting to packing the process maintains a smooth transaction and ensure safety for the workers. Because everything can be controlled by the PLC it only takes few people to run the whole production line.

As agriculture moves toward a greener future, investing in such technology not only supports sustainable farming but also contributes to global environmental preservation and food security. You can learn more about how LANE Heavy industry equipment for the liquid biofertilizer production line can help you create a fertilizer that are easily marketable and are in high demand.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Leave a Comment

Latest Posts

LANE has more than 500 successful cases and is committed to providing customers with first-class solutions, high-end machinery and equipment, and one-stop pre-sales, sales and after-sales comprehensive customer service.