Large Capacity Liquid Fertilizer Production Plant: Driving the Future of Smart Agriculture

Large capacity liquid fertilizer production plant are becoming indispensable assets for modern agricultural enterprises. As agricultural practices move towards precision agriculture and resource efficiency, the demand for liquid fertilizers has skyrocketed. Unlike traditional solid fertilizers, the formulations of liquid fertilizers can provide crops with nutrients that are quickly absorbed, reduce nutrient loss, and integrate seamlessly with irrigation systems. For enterprises and governments that prioritize food security, investing in such plants is not only a technical decision but also a strategic move towards sustainable agriculture.

The global agriculture industry is undergoing transformation. Population growth, climate stress, and soil degradation are reshaping how we approach food production. Farmers are under pressure to produce more with fewer inputs, and policymakers are encouraging eco-friendly fertilizers that minimize environmental impact.

Against this backdrop, a large capacity liquid fertilizer production plant provides:

The ability to supply national and regional markets with consistent, high-volume output

Reduced nutrient loss compared to conventional fertilizer applications

Compatibility with advanced fertigation and irrigation systems

The flexibility to develop customized formulations for specific crops and soils

By scaling production, these large capacity liquid fertilizer production plants act as enablers of sustainable farming and reliable food supply chains.

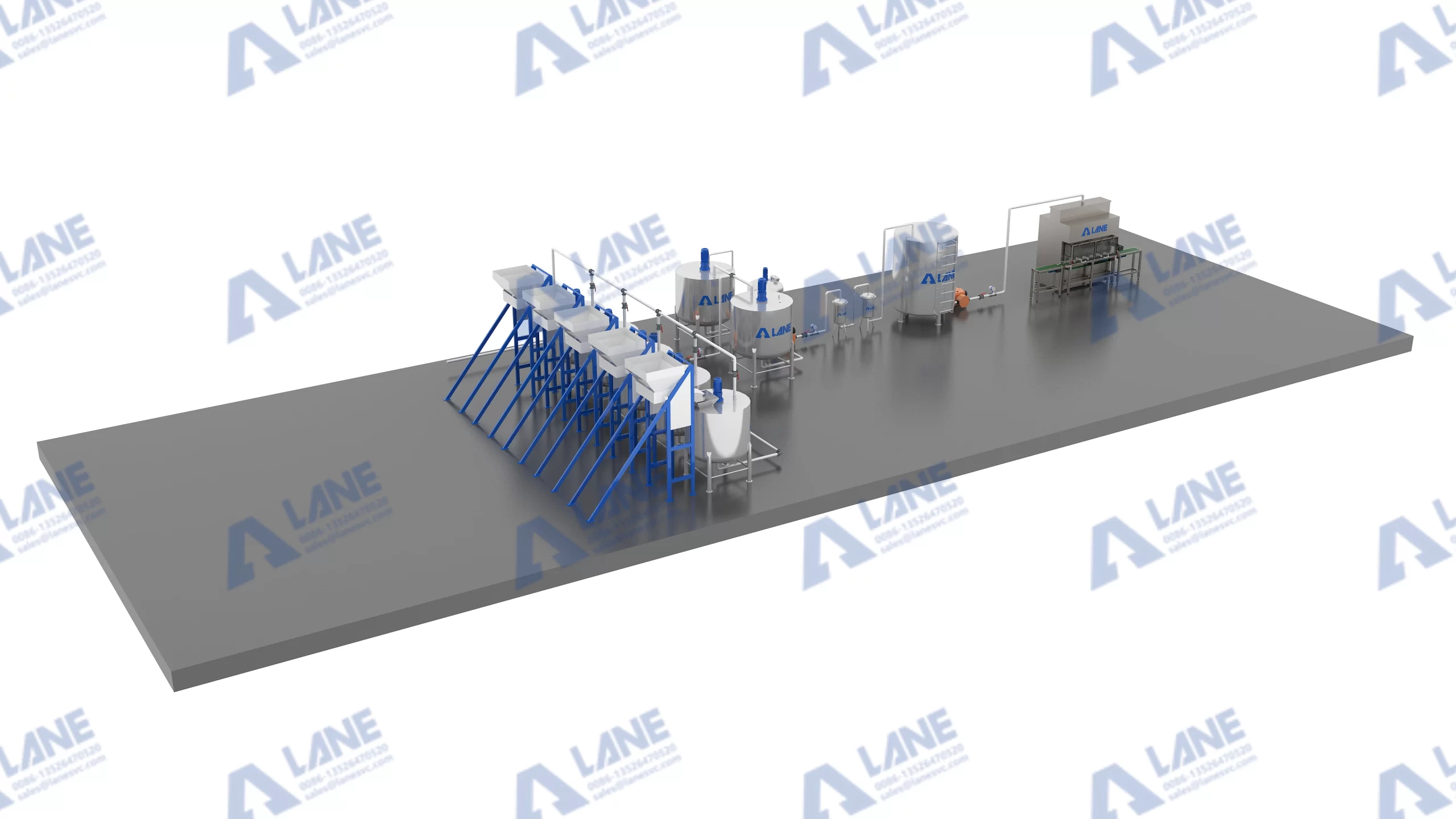

Designing and operating a plant of this scale requires integrating specialized equipment to ensure reliability, safety, and efficiency. Each part of the production line must function in harmony. Below are the essential systems:

| Component | Equipment Name | Function | LANE‘s Advantage |

| Raw material storage tanks | Stainless steel chemical storage tanks | Store and protect raw materials from corrosion and contamination | Constructed with anti-corrosive lining and adaptable for various fertilizer chemicals |

| Weighing & dosing system | Automated dosing scales with load cells | Guarantee precise measurement of raw inputs | High-accuracy dosing ensures consistent nutrient formulations |

| Mixing unit | High-shear industrial mixer with agitators | Achieve rapid dissolution of solids and uniform blending | Energy-efficient design, automated control, reduced mixing time |

| Heating & dissolution system | Steam boiler and plate heat exchanger | Speed up solubility of urea and phosphates | Optimized for energy savings and stable heat supply |

| Filtration line | Dual filters | Eliminate insoluble particles, protecting irrigation systems from clogging | Tailored mesh sizes to meet fertigation requirements |

| Quality control system | Inline pH meters, conductivity sensors, spectrophotometer | Monitor and control fertilizer concentration in real time | Integrated lab setup supports continuous quality assurance |

| Storage tanks | Agitated solution tanks with industrial pumps | Maintain stability of blended fertilizer solutions | High-capacity pumps prevent sedimentation and separation |

| Filling & packaging system | Automatic liquid filling machines, capping and labeling units | Prepare final products in IBCs, drums, or retail bottles | Flexible packaging formats for wholesale and retail markets |

LANE’s engineering expertise ensures these components are not just supplied as standalone equipment but integrated into a streamlined, turnkey production line tailored to client needs.

The success of a large capacity liquid fertilizer production plant relies heavily on the technologies driving its operations. Modern agriculture no longer accepts inefficiency or downtime; every component of the plant must function with precision, intelligence, and sustainability.

One of the most influential advancements is the adoption of fully automated PLC/SCADA systems. These platforms integrate sensors, pumps, mixers, and batching equipment into a digital control center. Factory operators can monitor nutrient concentrations, flow rates, and temperatures in real time, ensuring consistency in the production of thousands of tons of products. LANE further enhances this functionality by embedding predictive maintenance algorithms, which reduces unexpected downtime and extends equipment lifespan.

Another cornerstone is IoT monitoring. By connecting production data to cloud-based dashboards, managers can obtain practical insights into energy consumption, raw material efficiency, and overall factory performance. Remote access enables supervisors to make data-driven decisions from anywhere, thereby improving response speed and operational transparency.

Sustainability is no longer optional; it is mandatory. Advanced zero-emission water systems can treat and recycle the washing water within the factory. Solid residues are captured and reused, preventing environmental pollution while also creating opportunities for by-products such as micronutrient additives. This enables the factory to be both profitable and in compliance with environmental requirements.

Equally important is the flexibility of the formula. Thanks to the modular dosing and high shear mixing technology, the factory can switch between standard nitrogen-phosphorus-potassium fertilizers, nutrient-rich solutions, and customized formulas for hydroponic systems within a few hours. This flexibility not only enhances market competitiveness but also enables agricultural enterprises to quickly respond to constantly changing crop demands.

Essentially, today’s liquid fertilizer facilities can be regarded as intelligent factories: data-driven, energy-efficient, and highly adaptable. By integrating automation, the Internet of Things, and innovative environmental protection technologies, LANE ensures that each customer’s investment is not only oriented towards the future but also significantly exceeds that of traditional fertilizer factories.

| Feature | Solid Fertilizer Plant | Large Capacity Liquid Fertilizer Production Plant |

| Nutrient availability | Slow-release | Immediate absorption |

| Irrigation compatibility | Limited | Fully compatible |

| Formulation flexibility | Low | High |

| Environmental impact | Higher runoff risk | Reduced nutrient loss |

| Market demand trend | Stable | Rapidly expanding |

This comparison illustrates why investors and governments are increasingly prioritizing liquid fertilizer facilities.

(1) High Productivity for Expanding Markets

The foremost advantage of a large capacity liquid fertilizer production plant is its scale. With annual outputs ranging from 30,000 to 200,000 tons, these plants meet the demand of entire agricultural regions. High productivity guarantees stable contracts with distributors and government agencies. It also helps enterprises buffer against seasonal fluctuations, ensuring farmers have consistent access to fertilizers throughout the year.

(2) Cost-Effectiveness and Resource Optimization

Operating at scale lowers per-unit production costs. Bulk purchasing of raw materials, streamlined logistics, and automated systems all reduce operational expenses. Liquid fertilizers also require less downstream processing compared to granulated forms. For producers, this translates into competitive pricing and stronger market positioning, while for farmers, it means affordable and reliable inputs.

(3) Superior Crop Nutrition and Reliability

Liquid fertilizers deliver nutrients in a form that crops can absorb immediately. They integrate smoothly with fertigation systems, ensuring that nutrients reach plant roots evenly. A large-scale plant ensures consistency across every batch, building brand reliability and encouraging repeat business. This advantage becomes particularly critical in high-value agriculture, such as greenhouse farming and fruit cultivation, where precision is key.

(4) Flexibility and Rapid Customization

A large capacity liquid fertilizer production plant is not limited to one formula. With modular design, operators can adjust nutrient ratios, micronutrient blends, and pH levels quickly to match the results of soil tests or the needs of specific crops. This flexibility opens doors to customized solutions for niche markets, such as hydroponics, horticulture, and organic farming. Customization is no longer a costly option—it becomes a competitive advantage.

A leading agricultural conglomerate in the Middle East is facing the challenge of relying on imported granular fertilizers. These fertilizers have poor solubility in drip irrigation systems and the long supply chain leads to increased costs. Frequent blockages in the irrigation pipes also reduce crop yields and increase maintenance workload.

LANE provided a large capacity liquid fertilizer production plant tailored to the region’s needs. The plant is equipped with high-speed shear mixing equipment for quickly dissolving urea, an advanced filtration system to ensure no blockages in the solution, and a modular metering system capable of producing multiple formulations for dates, citrus fruits, and greenhouse crops.

After the debugging process, the customer reported that the irrigation was more smooth, the investment cost was reduced, and the nutrient management became more flexible. By producing fertilizers locally, the company also enhanced the resilience of its supply chain and aligned with regional sustainable development goals.

This project demonstrates how LANE’s expertise has transformed the constraints faced by agriculture in arid climates into opportunities for increased efficiency and long-term growth.

Q1: How large must a facility be to qualify as a “large capacity” liquid fertilizer plant?

A: Typically, annual output above 30,000 tons is considered large capacity.

Q2: Can one plant produce multiple formulations?

A: Yes. Modular design allows production of NPK blends, micronutrients, and specialty fertilizers within the same facility.

Q3: How long is the setup period?

A: Depending on scale, LANE can deliver turnkey projects in 6–12 months.

Q4: What is the expected ROI?

A: Most projects recover investment within 1–3 years.

Q5: Does LANE provide ongoing service?

A: Yes. LANE offers full lifecycle support, including installation, operator training, spare parts, and after-sales service.

Choosing the right technology provider for a large capacity liquid fertilizer production plant is more than a purchasing decision—it is a long-term strategic partnership.LANE not only provides advanced equipment but also offers a complete solution that includes engineering design, installation, operator training, and after-sales service, earning the trust of customers worldwide.

Our advantage lies in integrating advanced manufacturing technologies with practical agricultural insights, ensuring that each factory operates efficiently and is future-oriented. Leveraging our extensive experience in Asia, the Middle East, Africa, and other regions, LANE understands the unique challenges of different markets and adjusts its solutions accordingly.

By collaborating with LANE, agricultural enterprises not only obtain a large capacity liquid fertilizer production plant, but also acquire a reliable ally that is dedicated to innovation, sustainable development and measurable results. For enterprises aiming to expand their operations, reduce costs and ensure competitive advantages, LANE is always ready to become an ideal partner shaping the future of fertilizer production.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Leave a Comment

LANE has more than 500 successful cases and is committed to providing customers with first-class solutions, high-end machinery and equipment, and one-stop pre-sales, sales and after-sales comprehensive customer service.