The Role of Reactors and Mixing Systems in humic / fulvic acid liquid fertilizer Production

Humic / fulvic acid liquid fertilizer is made from natural raw materials such as lignite, peat, and compost. It has become one of the most crucial products in modern sustainable agriculture. Producing a superior humic / fulvic acid liquid fertilizer is not a simple process. It needs a precise bio-engineering process that can extract and activate the complex organic molecules from raw humates to create a stable, homogeneous solution.

Humic / fulvic acid liquid fertilizer can improve soil structure, enhance nutrient absorption of crops, promote root development, and increase plants’ stress resistance. Compared to traditional fertilizer, liquid fertilizer can be easily absorbed by plants. This is where the LANE liquid fertilizer production line becomes paramount. They provide equipment that has precise control of each process.

The reactor is the main machine of any liquid fertilizer production. This is where raw materials are transformed into solutions. The design of a reactor impacts the potency and quality of the final humic / fulvic acid liquid fertilizer.

If the reactor is the heart of the operation, then the mixer is the circulatory system. Proper mixing is critical for liquid fertilizer. From initial slurry creation, during the reaction/extraction phase, and most importantly during the final blending with other nutrients (NPK, micronutrients), a proper mixing system is essential.

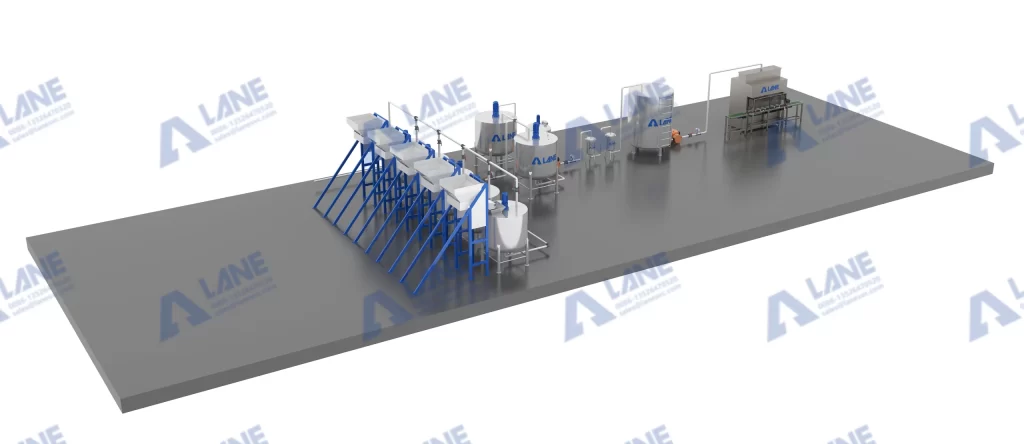

To create high-quality humic / fulvic acid liquid fertilizer, the reactors and mixers have to be a seamlessly integrated system. The humic / fulvic acid liquid fertilizer production line from LANE Heavy Industry is designed for seamless operation.

A typical LANE-integrated line includes:

This integrated approach, built around robust reactors and intelligent mixing, minimizes labor, maximizes raw material yield, and produces a market-leading, stable humic / fulvic acid liquid fertilizer.

In the production of humic/fulvic acid liquid fertilizer, reactors and mixing systems play a decisive role in improving the extraction rate of effective components, ensuring product uniformity and stability, and reducing production costs. The difference between a mediocre and a premium humic / fulvic acid liquid fertilizer is decided in the design of the production line. By integrating a production line from LANE Heavy Industry, producers can ensure optimal extraction, perfect homogeneity, and unparalleled product stability.

Q1: Why can’t I just use a standard tank and agitator to make humic/fulvic acid fertilizer?

A:Standard agitators often create insufficient shear to properly break down raw humates, leading to low extraction yields and long processing times. They also fail to prevent settling, causing inconsistent batches and potential clogging. The corrosive nature of the process also demands specialized, corrosion-resistant materials.

Q2: What is the most important feature to look for in a reactor for this application?

A: While material (stainless steel) is critical, the integration of precise temperature control and a mixing system designed for high-viscosity, solid-liquid suspension is paramount. A jacketed reactor with a powerful, multi-stage agitator system is ideal.

Q3: How does LANE Heavy Industry ensure mixing efficiency in large-scale production tanks?

A: LANE uses advanced CFD (Computational Fluid Dynamics) simulation to design tank geometry, baffle placement, and agitator type/size. This ensures full-volume coverage and optimal flow patterns, preventing dead zones even in tanks exceeding 20,000 liters.

Q4: Can LANE’s production lines be automated?

A: Absolutely. LANE specializes in turnkey systems with full PLC-based automation. This allows for precise control over reaction time, temperature, chemical addition, and mixing speeds, guaranteeing repeatable, high-quality batches of humic / fulvic acid liquid fertilizer with minimal operator intervention.

Q5: Can you customize a line for blending humic/fulvic acid with other liquid fertilizers?

A: Yes, customization is a core strength. LANE can design integrated lines that include dedicated reactors for humic extraction alongside blending tanks and inline mixers for precise formulation with NPK solutions, seaweed extracts, or other additives, creating tailored fertilizer blends.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Leave a Comment

LANE has more than 500 successful cases and is committed to providing customers with first-class solutions, high-end machinery and equipment, and one-stop pre-sales, sales and after-sales comprehensive customer service.