Humic-Acid-Water-Soluble-Fertilizer-Production-Line: A Complete and Clean Look Inside Modern Manufacturing

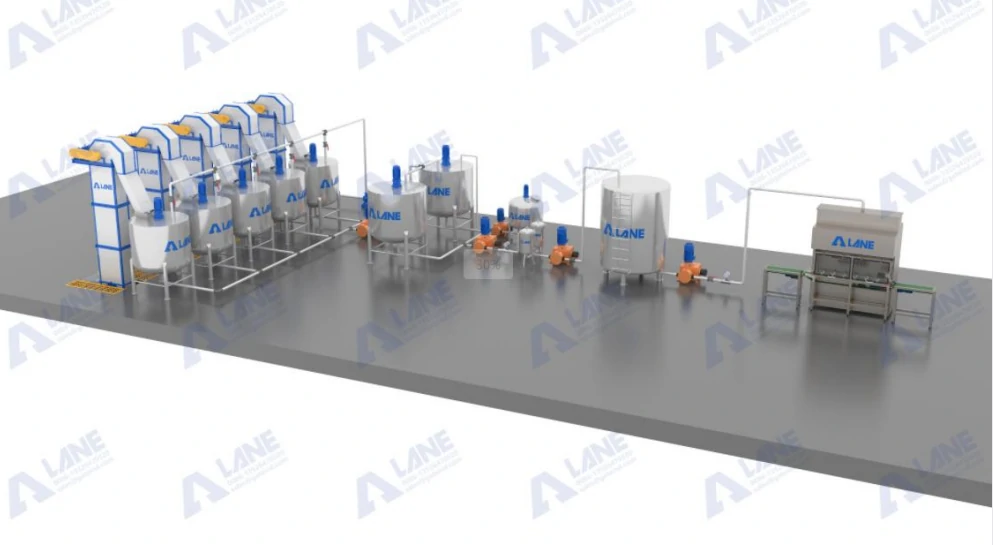

A modern agricultural market increasingly requires fast-acting, clean, and highly soluble fertilizers. That is why demand for professional humic-acid-water-soluble-fertilizer-production-line solutions has grown rapidly. These systems transform raw humic acid materials and supplementary nutrients into finely processed, fully soluble products that meet hydroponic, drip-irrigation, and foliar-feeding standards.

To help manufacturers understand exactly what equipment is required and why, this article walks through each major machine used in an efficient humic-acid water soluble fertilizer plant. By examining how each piece works, how they connect, and what advantages they offer, you can better plan or upgrade your own humic-acid-water-soluble-fertilizer-production-line for stable, long-term production.

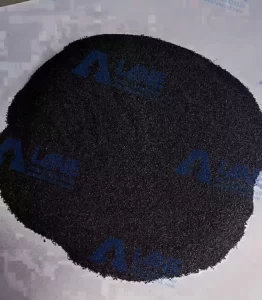

The first stage of any humic-acid-water-soluble-fertilizer-production-line is reducing raw materials to fine particles. Humic acid, amino acids, trace elements, and water-soluble carriers all need to be crushed to a consistent fineness to ensure quick dissolving later.

This vertical-crusher is designed for 1 to 3 tons of material per hour, with fineness adjustable between 80 and 120 mesh. Its power range of 22 to 37 kW allows efficient handling of even hard or granular raw materials. Because the machine is made from 304 stainless steel, it resists corrosion from acidic materials and maintains long-term stability.

The multi-stage blade structure gives this crusher excellent efficiency and accuracy. It operates with reduced noise and delivers around 40 percent improvement in crushing performance compared to simple single-blade systems. The finely crushed particles contribute directly to how well a fertilizer dissolves in water, making this step crucial for any humic-acid-water-soluble-fertilizer-production-line striving for premium quality.

Once materials are crushed, the next essential step is screening out impurities, oversized particles, and any remaining uneven fragments. The vibrating screening machine ensures only powder meeting the required mesh size proceeds to the batching stage.

With two to three layers of screens and accuracy of at least 95 percent, the machine carefully sorts materials at a rate of two to five tons per hour. Its power consumption stays in the practical range of 3 to 5 kW.

The multi-layer dynamic structure ensures clean separation, while the anti-clogging design greatly reduces downtime. These features allow the humic-acid-water-soluble-fertilizer-production-line to operate continuously without frequent maintenance. Uniform particle size is especially important because even a small clump can disrupt dissolving speed or create sediment in fertigation systems.

In the world of water-soluble fertilizers, accurate ingredient ratios matter. Even slight deviations in trace elements or nutrients can affect product performance. The automatic batching system makes precision possible.

With weighing accuracy controlled within plus or minus 0.1 percent, the batching system ensures that every formula remains consistent. Hopper capacity ranges from 1 to 5 tons, and users may select between 8 and 12 ingredient channels depending on how many raw materials their formulas require.

The system is equipped with a PLC touchscreen interface, allowing convenient parameter adjustments, recipe switching, and real-time monitoring. Dynamic compensation technology stabilizes accuracy even when working with light or highly flowable powders. For manufacturers using a humic-acid-water-soluble-fertilizer-production-line, this makes it possible to maintain consistent quality across thousands of batches.

The ability to store multiple recipes means switching between product types is fast and simple, supporting flexible production schedules and expanded product lines.

After ingredients are batched, the twin shaft mixer blends them thoroughly. This piece of equipment plays a major role in ensuring fertilizer dissolves completely and distributes nutrients evenly.

The mixer achieves at least 98 percent mixing uniformity. Batch time remains between three and five minutes, supporting high throughput without compromising consistency. Capacity options range from 500 to 2000 liters, making it suitable for operations of various scales.

The twin-screw, three-dimensional mixing structure ensures that materials move smoothly in all directions, eliminating dead angles and pockets of unmixed powder. The sealed housing prevents dust leakage, which is especially important when handling fine humic acid materials. For a humic-acid-water-soluble-fertilizer-production-line, this guarantees that every final product bag contains a perfectly mixed blend.

Water-soluble fertilizer production involves lots of fine powders, and without proper dust control, air quality, safety, and product purity can all be compromised. The dust removal system addresses these concerns.

This unit handles airflow ranges from 3000 to 8000 cubic meters per hour and achieves filtration levels of at least 99 percent. Power requirements range from 5.5 to 15 kW, depending on plant size.

Pulse-jet cleaning technology allows the filters to refresh themselves automatically, reducing cleaning frequency and maintaining stable suction throughout the production process. For any humic-acid-water-soluble-fertilizer-production-line, this system ensures a clean working environment, reduces waste, and protects employees from airborne particles.

Once powder is thoroughly mixed and dust-free, the final step is packaging. The quantitative packaging machine handles this with precision and speed.

It processes between 30 and 50 bags per minute and supports bag weights from 1 to 25 kilograms. Accuracy reaches plus or minus one gram, ensuring consistency even for small retail packages.

Driven by a servo motor for stable performance, the unit includes auto-correction functions and heat-sealing technology compatible with polyethylene, aluminum foil, and composite bags. Fast, accurate packaging helps a humic-acid-water-soluble-fertilizer-production-line maintain output efficiency and professional presentation.

Modern fertilizer lines benefit greatly from intelligent automation. The central control system synchronizes all equipment and provides real-time oversight.

Using industrial PLCs and HMI touchscreens, the system stores more than five years of production data. It communicates via Modbus or Ethernet, making it compatible with plant-level monitoring software or remote support platforms.

Fault alerts improve safety and reduce downtime. Remote maintenance support allows quick troubleshooting, which is particularly useful for overseas clients running a sophisticated humic-acid-water-soluble-fertilizer-production-line.

A well-coordinated humic-acid-water-soluble-fertilizer-production-line typically follows these steps:

The result is a high-quality, fully water-soluble product ideal for modern agriculture.

Our company, LANE, has focused exclusively on fertilizer machinery manufacturing in China for more than two decades. Over the years, we have built a dedicated engineering team capable of designing complete production lines tailored to client requirements. We not only build individual machines but also integrate full sets of water-soluble fertilizer, organic fertilizer, NPK, and compound fertilizer lines.

We maintain strict adherence to ISO 9001 and CE international quality standards across all equipment. Beyond manufacturing, we place strong emphasis on installation, commissioning, and long-term technical service. Whether you require maintenance, troubleshooting, upgrades, or remote assistance, we stay involved to keep your humic-acid-water-soluble-fertilizer-production-line at peak performance.

Our focus is always on delivering dependable, efficient, and intelligently designed fertilizer machinery, ensuring that every client’s production facility operates smoothly and sustainably.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Leave a Comment

LANE has more than 500 successful cases and is committed to providing customers with first-class solutions, high-end machinery and equipment, and one-stop pre-sales, sales and after-sales comprehensive customer service.