How to Scale Up Liquid Fertilizer Production Without Compromising Quality

In recent years, the fertilizer industry is seeing a massive bloom. The continuous advancement of technology and fertilizers, along with massive new interest in farms and farm life, has created global and local demand for liquid fertilizer. It has gained widespread popularity due to its high nutrient absorption rate and flexible application methods. For fertilizer manufacturers, rising demand means opportunity—but also raises the question of how to scale up liquid fertilizer production efficiently and reliably.

Scaling up liquid fertilizer production has become a priority to capture emerging market opportunities. However, the path to increasing output is risky, and a misstep in scaling can lead to inconsistent batches, nutrient segregation, sedimentation, and ultimately, a damaged reputation. The central challenge remains how to scale up liquid fertilizer production while maintaining product integrity and consistent quality.

Scaling up is an issue that can directly affect brand reputation and farmer trust. This article will guide you through proven strategies on how to scale up liquid fertilizer production and explore practical solutions for sustainable expansion.

Before you purchase any single new piece of equipment, you must establish your groundwork.

Audit Your Current Process: Your first task is identifying your bottlenecks in the existing line. Is your production line slow, have inadequate mixing, or limited storage? Understanding these pain points will prevent inefficiencies.

Revisit Formulation Science: Scaling up is not only about making more fertilizer. A high-capacity fertilizer needs formulation adjustments. A 1,000L batch may behave differently in a 10,000L batch. You have to conduct stability and compatibility tests to preempt issues like salt crystallization or gel formation.

Design for Flow: Map your future production flow. Plan how you want your raw materials handled. A linear, efficient flow reduces handling, contamination risk, and production time.

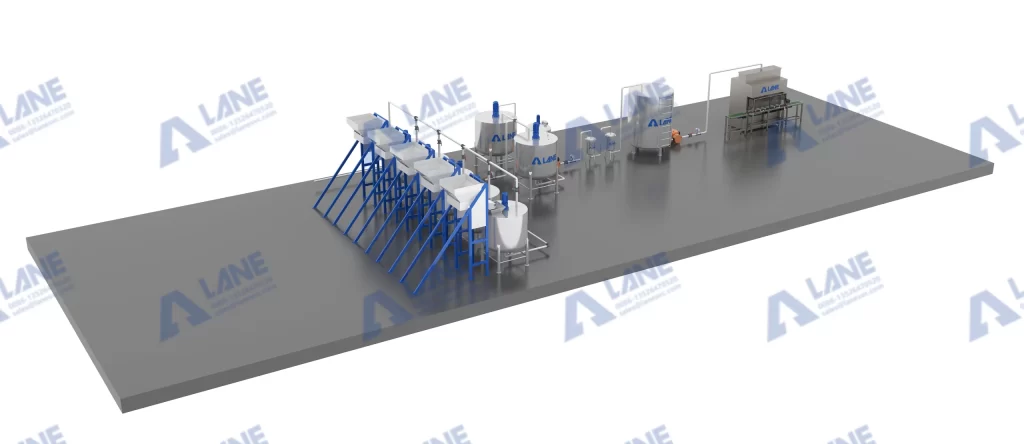

This is when you identify the core machines for your expansion. Upgrading to purpose-built industrial machinery is essential for quality and scale. LANE Heavy Industry’s engineered solutions address the core needs of a scaled-up operation.

High-Capacity, Precision Mixing Systems: The most important factor of a fertilizer production line is precision. Moving from simple agitators to LANE’s High-Shear Mixing Reactors ensures complete homogenization. LANE’s stainless-steel mixers create intense hydraulic and mechanical shear and incorporate base raw material powders like NPK nutrients into the liquid base. This creates a stable, uniform suspension that resists settling during storage. This is the first answer to how to scale up liquid fertilizer production.

Automated Batching and Dosing Stations: LANE’s production line promotes precision and efficiency. We provide Automated Ingredient Handling Systems with precise load cells and PLC controls. Manual measurement creates error in a high-volume liquid fertilizer production line. This automated system ensures accuracy batch after batch. This repeatability is key to maintaining formulation.

Scalable Storage and Curing Tanks: Scaling production also means scaling storage. LANE supplies large-volume storage tanks with customized options. Our storage tanks are made with food-grade SS304 or SS316. They are easy to drain and clean. We also provide slow-speed agitator tanks for specialized formulas. This type of tank can store suspensions for a long time without settling and prevents dead zones.

Industrial Filtration and Packaging Lines: A liquid fertilizer production line without proper filtration is damaging for the brand. LANE’s High-Throughput Filtration Units remove any undissolved particulates before packaging, ensuring a flawless product. After filtration and storage, the liquid fertilizer is sent to the filling machine.

The process from mixing to filling is fully automated, seamless, fast, and without any human touch.

The secret of how to scale up liquid fertilizer production is process and quality control. Machines enable scale, but process control guarantees quality.

Standard Operating Procedures (SOPs): Document every step of the production process. From the raw material list and storage to mixing times, temperatures, cleaning protocols, and maintenance schedules is part of this. The LANE Heavy Industry production line involves sensors in every part of the process and can automatically note the data to your system for complete clarity.

In-Line Quality Checks: The production line should have implemented sensors for pH, density, and conductivity to monitor batch parameters in real-time. This allows you to make micro-adjustments during production.

Preventive Maintenance: Industrial equipment should always be maintained properly. Scheduled inspection of seals, shafts, and motors prevents unexpected downtime and protects product quality from equipment degradation.

Knowing how to scale up liquid fertilizer production will help you overcome the technical challenge of scaling a liquid fertilizer production line. It will help you scale production without compromising quality.

Scaling a liquid fertilizer production line is achievable through the right combination of process optimization and advanced equipment. It’s not about bigger machines; it’s about better, smarter engineering and a partnership with a provider who understands the equipment. LANE Heavy Industry implements strict quality control measures throughout the production process to ensure your product is premium.

Q1: What is the most common quality issue when scaling up liquid fertilizer production?

A: The most common issue is incomplete homogenization and subsequent settling or “salting out.” This occurs when mixing energy is insufficient for the larger volume, leading to uneven nutrient distribution. Upgrading to high-shear industrial mixers is the primary solution.

Q2: Can I simply add a larger agitator to my existing tank to scale up?

A: Often, no. Scaling mixing is not linear. A larger tank requires a fundamentally different mixer design and power input to achieve the same fluid dynamics. Retrofitting can be ineffective. A dedicated, scaled mixing system from LANE is typically required.

Q3: How important is automation when scaling?

A: Critical. Automation in batching and dosing ensures repeatable accuracy, reduces labor costs, and enhances safety by minimizing worker exposure to raw materials. It is a key investment for maintaining quality control at higher throughputs.

Q4: Does LANE Heavy Industry provide support beyond just selling the machinery?

A: Yes. LANE provides comprehensive support, including process consulting, factory layout planning, installation supervision, and operator training. This ensures your new production line is optimized and your team is equipped to run it effectively from day one.

Q5: How do we manage waste and cleaning (CIP) in a scaled-up system?

A: Scaled systems benefit greatly from Clean-in-Place (CIP) systems. LANE can design tanks and piping with CIP capabilities, using automated spray balls and sequenced flushing to clean interiors without disassembly, saving time, water, and chemicals while improving hygiene.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Leave a Comment

LANE has more than 500 successful cases and is committed to providing customers with first-class solutions, high-end machinery and equipment, and one-stop pre-sales, sales and after-sales comprehensive customer service.