How to Make Liquid Fertilizer from Animal Manure–A Complete Guide to Waste-to-Wealth Farming

In the modern agricultural landscape, liquid fertilizer from animal manure is becoming one of the most valuable tools for farmers seeking higher yields, healthier soils, and reduced environmental impact. Instead of letting animal manure accumulate and cause waste management issues, this process transforms it into nutrient-rich liquid fertilizer that can be applied directly to crops. With the right technology—such as LANE’s custom-engineered solutions—this transformation becomes both efficient and profitable.

Producing liquid fertilizer from animal manure not only reduces the harmful effects of untreated livestock waste but also creates a valuable and marketable product. Manure contains essential nutrients like nitrogen, phosphorus, and potassium (NPK), along with beneficial organic matter that improves soil structure. When converted into liquid form, these nutrients are more readily available for plant uptake, enhancing crop performance while minimizing nutrient loss. Beyond environmental benefits, this approach reduces dependence on costly chemical fertilizers, promotes circular farming practices, and supports long-term soil fertility.

The main feedstock comes from:

Dairy cow manure – High in nitrogen and potassium, excellent for pasture and cereal crops.

Poultry litter – Rich in phosphorus and micronutrients.

Pig manure – Balanced NPK content, useful for vegetable and fruit crops.

Mixed farmyard manure – A blend from various livestock, offering diverse nutrient profiles.

Some farms also combine manure with crop residues, food waste, or plant-based compost to enhance nutrient composition.

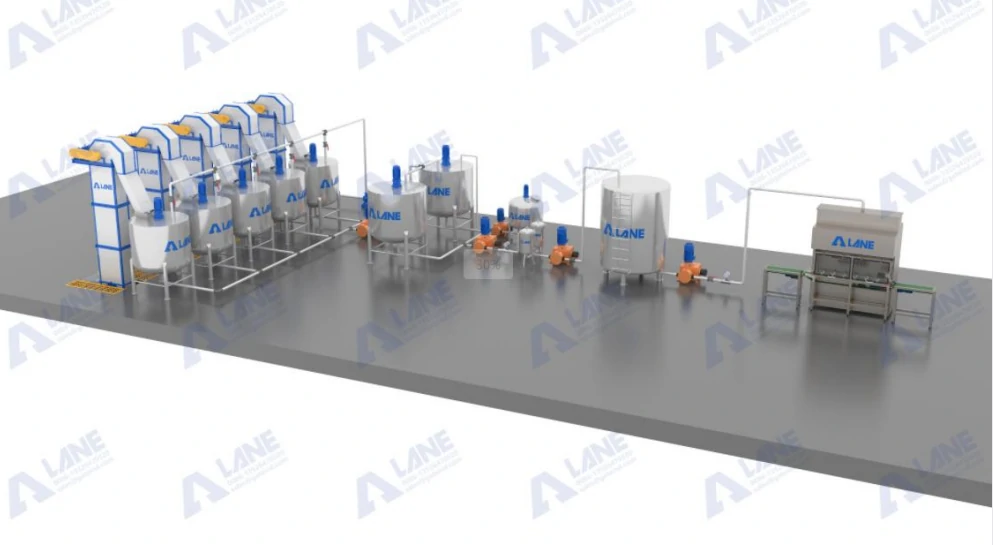

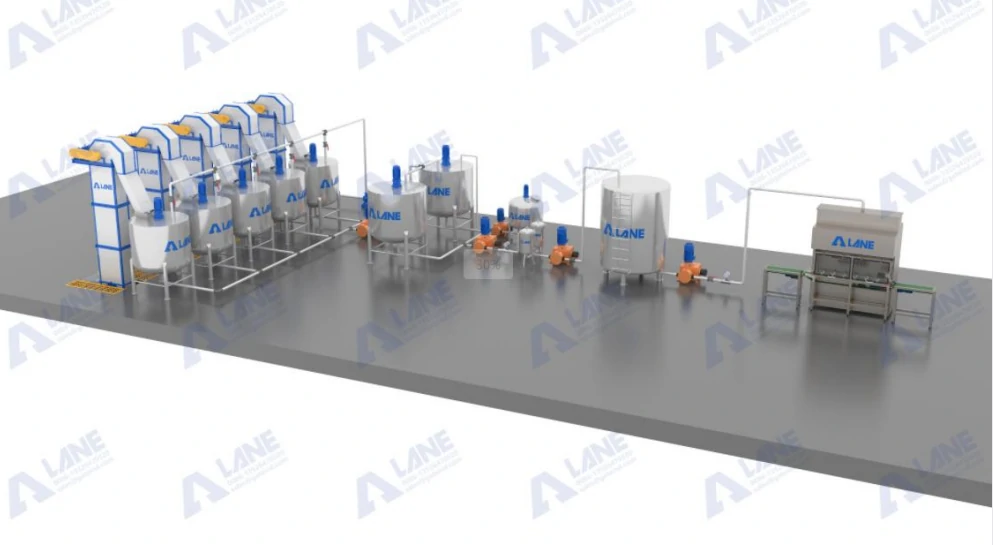

Below is a typical LANE-designed process for producing liquid fertilizer from animal manure:

| Step | Process | Purpose |

| Raw Material Feeding Hopper | Loads manure into the system | Ensures consistent material input |

| Manure Mixing Tank | Blends manure with water | Adjusts moisture and improves mixing |

| Additive Mixing Tank | Adds micronutrients or beneficial microbes | Customizes fertilizer formula |

| Duplex Filtration | Removes solids and impurities | Prevents clogging in irrigation systems |

| Storage Tank | Holds processed liquid | Ready for final packaging |

| Liquid Packing Machine | Packages fertilizer into drums, bottles, or IBC tanks | Makes distribution easier |

LANE offers complete equipment lines built from corrosion-resistant stainless steel, ensuring durability in harsh operating conditions. Common components include:

Manure Pumps & Feed Hoppers – Handle high-moisture materials with ease.

High-Capacity Mixing Tanks – Guarantee consistent nutrient blending.

Duplex Filters – Critical for removing fine debris and protecting drip irrigation.

Automated Filling Lines – Reduce labor costs and ensure precise packaging.

LANE’s modular design means farmers can scale production easily as demand grows.

At LANE, we know that no two farms are the same. The way you handle manure, the space you have available, and the crops you grow all affect how your liquid fertilizer from animal manure production line should be designed. That’s why we don’t believe in “one-size-fits-all” equipment. Instead, we work closely with farmers to create systems that fit their exact needs.

Our process starts with a simple conversation. We listen to your challenges—whether it’s dealing with large volumes of manure on a dairy farm, turning poultry waste into market-ready fertilizer, or finding a compact solution for a small family operation. Then, our engineering team designs a production line that uses corrosion-resistant stainless steel, smart automation, and easy-to-maintain components. We make sure your liquid fertilizer from animal manure line is not only efficient but also cost-effective. We can integrate features like duplex filtration to prevent irrigation clogs, nutrient dosing systems to meet specific crop requirements, and automated filling machines for fast, accurate packaging.

When it’s time to set up, our technicians handle on-site installation and train your team to operate the equipment with confidence. And we don’t stop there—LANE offers long-term after-sales service, spare parts support, and even remote monitoring to make sure your system runs smoothly for years.

Whether you’re running a small cooperative or a large-scale commercial farm, LANE gives you the tools and support to turn manure into a steady source of profit while protecting the environment.

Q1: Can liquid fertilizer from animal manure be used in drip irrigation systems?

Yes. When properly filtered through duplex filtration, it works perfectly in drip irrigation without clogging emitters.

Q2: Is it safe for all types of crops?

Yes. The nutrient profile can be adjusted to meet the needs of different crops, from cereals to vegetables.

Q3: What makes LANE’s equipment different?

LANE focuses on stainless steel construction, advanced automation, and end-to-end support, ensuring durability and efficiency.

Producing liquid fertilizer from animal manure is not just a waste management solution—it’s a strategic investment in soil health, crop productivity, and farm profitability. With LANE’s advanced equipment, tailored designs, and unmatched service, turning animal waste into high-quality liquid fertilizer becomes a sustainable and rewarding venture.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Leave a Comment

LANE has more than 500 successful cases and is committed to providing customers with first-class solutions, high-end machinery and equipment, and one-stop pre-sales, sales and after-sales comprehensive customer service.