Maximizing ROI: The Complete Guide to a High-Efficiency Liquid Fertilizer Production Line

In today’s competitive agricultural market, the ability to produce consistent high quality liquid fertilizer is a profitable venture. However, not all production lines are created equal. Investing in a high-efficiency liquid fertilizer production line is sets you apert from your competition. The global agricultural industry is now fully focused on precision and efficiency. This creates an increased demand for liquid fertilizer.

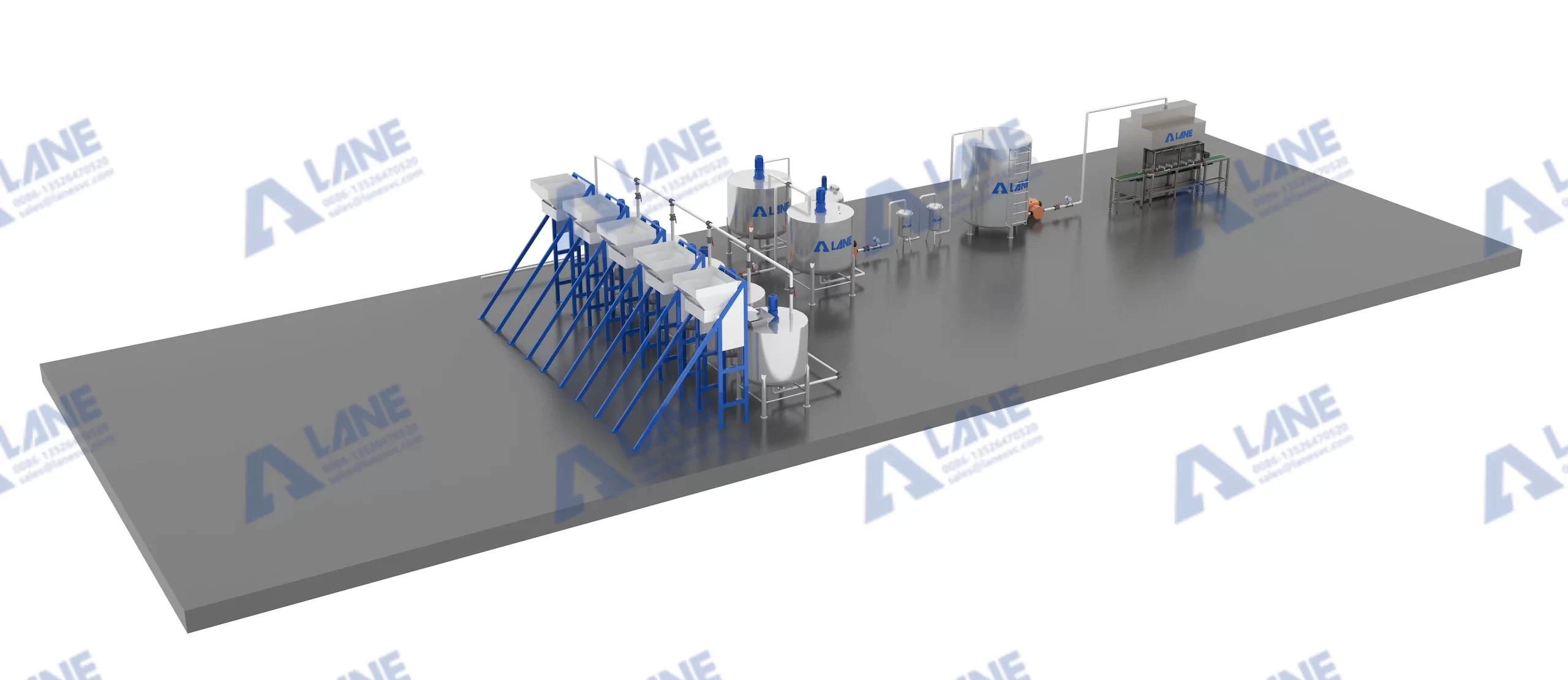

LANE Heavy Industry, a leader in the fertilizer industry creates tailored high-efficiency liquid fertilizer production line that integrates automation, energy conservation, and flexibility. It helps enterprises break through the bottlenecks of traditional production such as low efficiency, high labor costs, and unstable product quality. This guide will dissect how to leverage LANE Heavy Industry’s High-efficiency liquid fertilizer production line to optimize operational efficiency and its ROI potential.

A high-efficiency liquid fertilizer production line doesn’t only mean basic mixing. It’s a system designed to optimize every stage of the process. The process starts with raw material handling and precise formulation to homogenization, reaction, and final packaging. Key hallmarks of efficiency include:

LANE’s systems are engineered as a closed unit where each component amplifies the others’ performance. A standard high-efficiency liquid fertilizer production line from LANE integrates:

ROI is directly interconnected with a high-efficiency liquid fertilizer production line. It is realized through multiple, simultaneous cost savings and value-generation channels:

While initial investment in a high-efficiency liquid fertilizer production line is higher than a basic setup, the financial picture becomes compelling when analyzing operational gains.

Sample ROI Consideration Table:

| Factor | Basic Manual Line | LANE High-Efficiency Line |

| Production Output | 2-3 tons per 8-hour shift | 5-8 tons per 8-hour shift |

| Labor Required | 3-4 operators | 1-2 operators |

| Batch Consistency | Variable, prone to error | >99% consistent, automated |

| Raw Material Waste | Estimated 3-5% | Estimated <1% |

| Scalability | Difficult, requires new line | Easy, modular expansion |

Payback Period Calculation:

The reduced waste, labor savings, and increased output allows a LANE high-efficiency liquid fertilizer production line to achieve the payback within 1 to 3 years depending on scale and local market factors. Subsequent years then contribute to higher profit margins.

LANE Heavy Industry has over 20 years of experience in the fertilizer industry. We are not just an equipment supplier; we are also a partner in your production success. Our expertise in building robust, reliable fertilizer production line solutions is backed by:

Investing in a high-efficiency liquid fertilizer production line is an investment in the profitability and longevity of your fertilizer business. It’s about creating a high-quality liquid fertilizer by leveraging precision equipment to make a profit.

Q1: What is the typical lead time for a complete high-efficiency liquid fertilizer production line from LANE?

A1: Lead times vary based on the complexity and customization of the system. Generally, a standard line can be delivered within 60 to 90 days after final design confirmation. More complex, fully automated lines may require 90-120 days.

Q2: Can the production line handle both clear solutions and suspensions/slurries?

A2: Yes. LANE’s high-efficiency liquid fertilizer production lines are designed with versatility in mind. By selecting the appropriate reactor type and integrating high-shear mixers or homogenizers, the same line can efficiently produce both clear liquid fertilizers and uniform suspension fertilizers.

Q3: How much factory space is required for a typical line?

A3: Space requirements depend on the targeted output. A compact, integrated line for small to medium output might fit in an area of 200-400 square meters. We provide detailed plant layout drawings during the design phase to optimize your existing space.

Q4: Does LANE provide training and after-sales support?

A4: Absolutely. We provide comprehensive on-site training for your production and maintenance teams during commissioning. Our after-sales support includes detailed operation manuals, online technical assistance, and a readily available supply of wear parts to ensure your fertilizer production line operates smoothly for years to come.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Leave a Comment

Latest Posts

LANE has more than 500 successful cases and is committed to providing customers with first-class solutions, high-end machinery and equipment, and one-stop pre-sales, sales and after-sales comprehensive customer service.