Harnessing Molasses Fermentation for Liquid Fertilizer Plant Efficiency

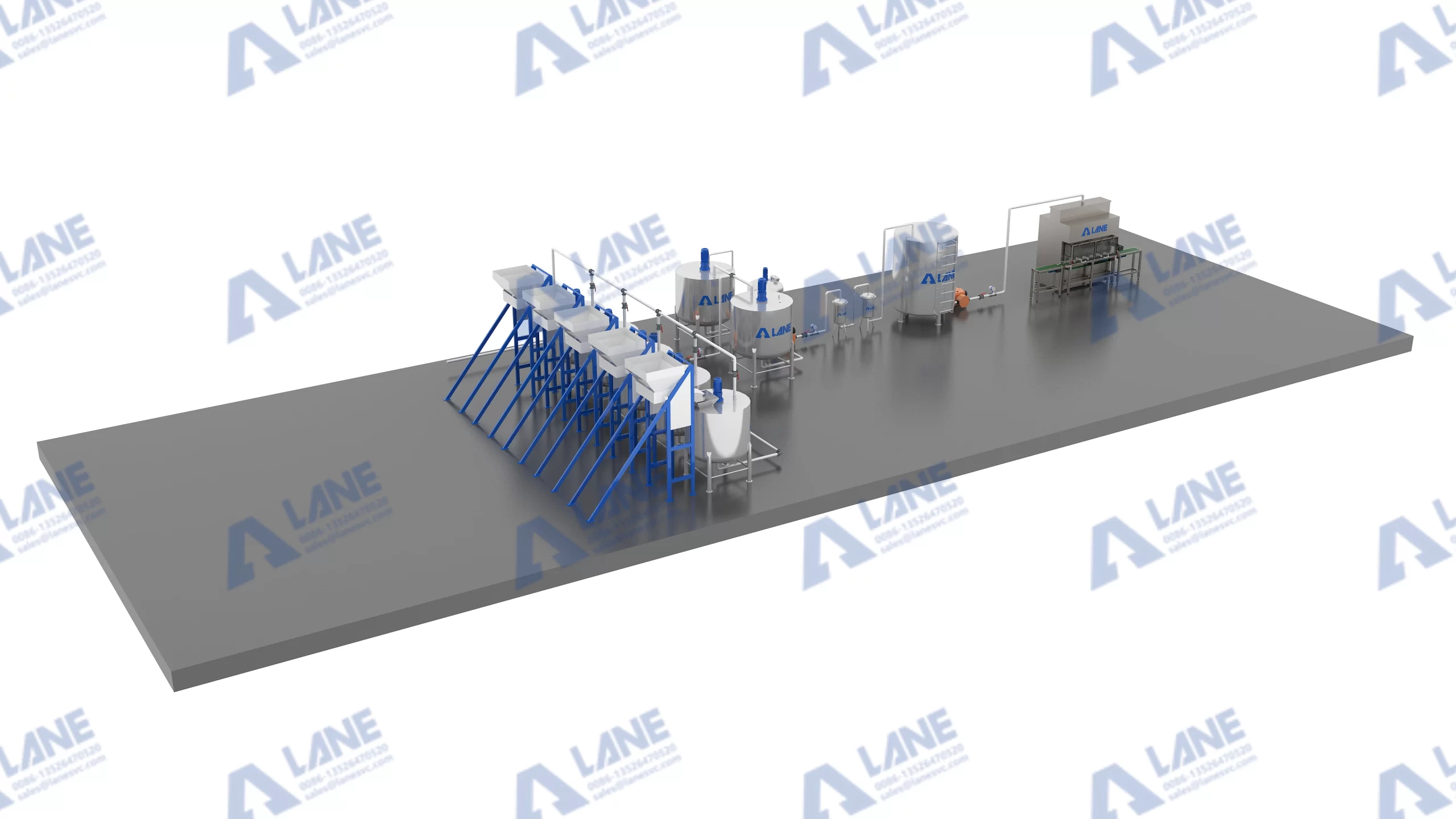

Molasses fermentation for liquid fertilizer plant operations has become an increasingly popular method for producing high-quality, nutrient-rich fertilizers. At its core, this process transforms molasses, a by-product of sugar refining, into a powerful input for sustainable agriculture. By leveraging microbial fermentation, plants can convert molasses into liquid fertilizers that improve soil fertility, crop resilience, and overall productivity. Companies like LANE Heavy Industry Machinery have advanced this approach with reliable fermentation systems, modern production lines, and decades of experience across more than 40 countries.

Molasses fermentation for liquid fertilizer plant systems is not just a production method; it is a strategy for building a more sustainable and resilient agricultural economy.

Sustainable use of by-products: Molasses, often considered waste in sugar processing, is transformed into a high-value input for farming. This helps reduce industrial waste and promotes circular economy practices.

Enhanced nutrient content: Fermentation enriches molasses with amino acids, enzymes, and organic acids that improve plant nutrient absorption.

Microbial benefits: Fermented molasses acts as a probiotic for soil, boosting populations of beneficial microorganisms that improve soil texture and fertility.

Cost-effective production: Farmers gain access to affordable fertilizer alternatives, reducing reliance on costly synthetic inputs.

Scalability: From smallholder farms to industrial fertilizer plants, molasses fermentation can be tailored to fit different production scales.

Global food security: By lowering fertilizer costs and improving yields, this method contributes directly to addressing food security challenges worldwide.

Molasses contains sugars, minerals, and trace elements that serve as feedstock for microbial growth. During fermentation:

Microorganisms (often yeast, lactobacillus, or other beneficial strains) metabolize sugars.

The process yields bioactive compounds that enhance soil and plant health.

Aeration, pH control, and temperature management are critical to maintain fermentation efficiency.

This natural biotransformation is the foundation of liquid fertilizer plants built around molasses fermentation.

What happens: Receive molasses deliveries (tanker or drums), sample and test for Brix (sugar concentration), ash, foreign solids, pH and microbial load. Record batch data for traceability.

Why it matters: Incoming variability in molasses (viscosity, solids, contaminants) strongly affects fermentation performance and consistency. Early corrections reduce downstream problems.

Typical actions & equipment:

Stainless Steel Storage Tank (raw molasses): A jacketed, heated tank with level sensors and agitator holds raw molasses at 30–60 °C to maintain pumpability. Tanks are fitted with CIP nozzles and sight glasses.

Dual Filter (coarse + fine): A two-stage filtration unit removes bagasse, fibers and coarse impurities (first stage, 1–5 mm), followed by a fine filter or bag/cartridge filter (second stage, 50–200 µm) to protect pumps, strainers and downstream fermenters.

Practical targets: Dilute to a working Brix of 8–18% depending on strain and fermentation design; target total solids <18% for most aerobic processes.

What happens: Molasses is diluted with process water, nutrients (if required), and any additives (pH buffers, antifoam). This creates a homogeneous feed for the seed culture and main fermenter.

Key equipment:

Stainless Steel Mixing Tank: Equipped with a variable-speed agitator, baffles, and load cells for accurate batching. Inline static mixers or recirculation pumps accelerate homogenization.

Metering/Dosing Pumps: For precise addition of micronutrients, trace elements or inoculum.

Control points: Measure Brix, temperature and viscosity; adjust dilution to maintain pumpable viscosity and the target sugar concentration for the chosen microbial strain.

What happens: A small-volume seed fermenter grows the starter culture to the desired vitality before transfer to the main fermenter. Proper seed staging shortens lag time and improves yield.

Typical equipment:

Small Stainless Steel Fermenter: Jacketed and equipped with aeration, pH probe, DO probe and heating/cooling.

Sterilization & CIP capability: Depending on microbial strain and hygiene requirements, seed tanks may be sterilized or sanitized between batches.

Operational tips: Inoculum size often ranges 1–5% v/v of the production fermenter; pre-adapt cultures to the actual molasses feed to reduce shock.

What happens: The diluted molasses feed is fermented under controlled conditions to produce the targeted bioactive metabolites and microbial biomass that constitute the liquid fertilizer.

Core equipment and controls:

Stainless Steel Fermenter / Bioreactor: With high-efficiency agitator, sparger for aeration, pH and DO sensors, heating/cooling jacket and access ports for sampling. Volumes vary from a few cubic meters to several hundred, depending on scale.

Aeration Blower / Compressor and Air Filters: Provide sterile or filtered air; flow control via mass flow controllers.

PLC / SCADA Control: Automated control of temperature, pH, DO and agitation to follow fermentation recipes and log process data.

Process parameters: Typical aerobic ranges: temperature 28–34°C, pH 5.5–6.5 (strain dependent), dissolved oxygen >20% saturation (or a specific mg/L), agitation tuned to keep solids suspended without shearing microbes.

Byproduct handling: Foam sensors and antifoam dosing keep the surface under control. Inline sampling ports enable rapid QC checks.

What happens: Remove microbial floc, unfermented solids and fine particulates to produce a stable, pumpable product.

Separation equipment:

Decanter Centrifuge / Disc-Stack Centrifuge: Removes biomass and fine solids—disc-stack for high clarification, decanter when substantial solids are present.

Dual Filter (polishing stage): After centrifugation, a second-stage dual filtration (coarse followed by cartridge) polishes the liquid to required clarity.

Liquid–Liquid Centrifugal Extractor (optional): If the process includes extraction of hydrophobic bioactives, oil separation or solvent recovery, a liquid–liquid centrifugal extractor can rapidly separate immiscible phases with high throughput. Note: this is situational—most straightforward molasses fertilizer lines do not require LLE unless co-products or contaminants necessitate phase separation.

Conditioning steps: Adjust pH, add stabilizers, dissolve micronutrients or chelators and homogenize in a mixing tank. This is also where concentration or dilution to the target application strength is carried out.

What happens: Achieve the final product specification—concentration, microbial count (if living microbes are the goal), and shelf stability.

Equipment & choices:

Vacuum Evaporator or Thin-Film Concentrator (optional): Concentrates the product when a higher nutrient density is required.

Heat Exchanger / Pasteurizer: A moderated thermal treatment can stabilize the product (reducing unwanted microbes) while preserving beneficial metabolites.

Final polishing filters ( cartridge / micron filters ): Reach desired turbidity and particle size distribution before packaging.

What happens: Transfer the conditioned liquid to consumer- or bulk-packaging in a hygienic, measured way.

Liquid Packaging Machine options:

Pump-driven volumetric fillers: Accurate for viscous fertilizers; suitable for drums, pails and IBCs.

Rotary/linear rotary fillers with capping and labeling: For bottles and retail packs—can be configured as aseptic lines for long shelf life.

Drum/IBC filling stations with flow meters and cam-lock fittings: For large-scale dispatch.

Related equipment: In-line check meters, automatic cappers, labelers and metal detectors if required by the end market.

What happens: Store finished product under controlled conditions and prepare for dispatch.

Stainless Steel Storage Tank (finished goods): Jacketed if temperature control is needed; equipped with level indicators, recirculation pumps to prevent settling, and nitrogen blanketing when oxidation must be minimized.

Load-out & transfer pumps: Sanitary centrifugal pumps and flow meters ensure accurate loading to tankers or totes.

Batch records & QC: Maintain full traceability—lab test results for pH, EC, viscosity, microbial assays and certificate of analysis (CoA) accompany each shipment.

The adoption of molasses fermentation in fertilizer production lines delivers a variety of strategic benefits:

Environmentally friendly: The process reduces dependency on synthetic fertilizers that can damage ecosystems, while lowering industrial waste from sugar refineries.

Improved crop yields: Fermented liquid fertilizers enhance nutrient uptake and root development, resulting in stronger and higher-yielding plants.

Enhanced soil health: Continuous application improves soil porosity, water retention, and microbial activity, leading to healthier long-term soil structure.

Flexibility in formulations: Farmers can adjust molasses fermentation methods to enrich fertilizers with specific microbial strains tailored to crop needs.

Resilience in agriculture: By promoting natural soil fertility, farmers reduce vulnerability to market fluctuations in chemical fertilizer pricing.

Integration with modern systems: Plants equipped with advanced LANE fermentation lines can scale production seamlessly while ensuring consistency.

LANE’s technology ensures that each stage of this process is optimized, with durable equipment such as fermenters, mixers, pumps, and packaging systems that are designed for longevity and performance.

Countries with large sugar industries, such as Brazil, India, and Thailand, have implemented molasses fermentation at scale. In Africa and Southeast Asia, liquid fertilizer plants using this approach are helping smallholder farmers cut fertilizer costs while maintaining productivity. LANE has played a vital role in supporting these global initiatives with complete production lines, tailored equipment, and after-sales service.

Case Example: LANE Collaboration

In a Southeast Asian project, LANE provided a complete liquid fertilizer production line based on molasses fermentation. The plant achieved:

30% cost reduction compared to synthetic fertilizers.

20% increase in crop yields for rice and maize farmers.

Sustainable operation, with minimal waste and strong farmer adoption.

Beyond this case, LANE’s solutions have been deployed in multiple regions:

These projects show that molasses fermentation is not only a technical process but also a socio-economic solution, helping farmers secure livelihoods and ensuring sustainable farming systems.

Future developments may include:

AI-powered monitoring systems to automate pH, temperature, and aeration adjustments.

Integration with renewable energy to power fermentation units sustainably.

Smart packaging solutions for better storage and application efficiency.

Q1: Why is molasses chosen for liquid fertilizer production?

Because it is rich in sugars and trace nutrients, making it an ideal feedstock for fermentation.

Q2: Can farmers make their own fermented molasses fertilizer?

Yes, but industrial-scale plants like those supported by LANE ensure consistency, quality, and safety.

Q3: How does molasses fermentation improve soil health?

It increases organic matter, fosters beneficial microbes, and enhances nutrient cycling.

Q4: Is molasses fermentation suitable for all crops?

Generally yes, though application rates vary depending on crop type and soil conditions.

Q5: What sets LANE apart in this field?

Over 40 countries trust LANE for advanced fertilizer equipment, comprehensive production lines, and expert after-sales support.

Molasses fermentation for liquid fertilizer plant systems offers a sustainable, cost-effective, and highly efficient pathway for modern agriculture. With growing global demand for eco-friendly fertilizers, this process transforms agricultural by-products into valuable plant nutrition. Backed by experienced providers like LANE Heavy Industry Machinery, farmers and producers can rely on proven equipment, complete production lines, and dedicated support to unlock the full potential of molasses fermentation.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Leave a Comment

LANE has more than 500 successful cases and is committed to providing customers with first-class solutions, high-end machinery and equipment, and one-stop pre-sales, sales and after-sales comprehensive customer service.