How Greenhouse Liquid Fertilizer Equipment Improves Crop Growth and Efficiency

Modern greenhouse farming has changed the way the world grows food — offering precise control over climate, light, and irrigation. Yet, even the most advanced greenhouse cannot reach its full potential without efficient nutrient management. That’s where greenhouse liquid fertilizer equipment comes in.

A greenhouse liquid fertilizer equipment system allows farmers to deliver nutrients directly to plants in a controlled, efficient, and automated way. Whether used for vegetables, flowers, or hydroponic crops, this technology ensures every plant gets exactly what it needs — no more, no less.

In this article, we’ll explore how greenhouse liquid fertilizer systems work, what equipment is included, and why LANE Heavy Industry has become a trusted partner in designing complete fertilizer solutions for greenhouse cultivation.

Greenhouse liquid fertilizer equipment refers to a set of machines and control systems used to prepare, mix, and distribute liquid fertilizers to crops under controlled greenhouse conditions.

Unlike traditional solid fertilizers that must be spread manually and dissolve slowly, liquid fertilizers are dissolved in water and supplied through irrigation systems such as drip or sprinkler systems.

This process — known as fertigation — combines fertilization and irrigation, optimizing plant nutrient uptake while saving labor and resources.

In short: Greenhouse liquid fertilizer equipment turns nutrient application into a precise, automated process that ensures higher yields and more sustainable production.

Greenhouse crops are often grown in confined spaces and under controlled conditions, meaning nutrients must be supplied in exact proportions. A liquid fertilizer system offers several advantages over traditional fertilizer methods:

Precision control: Adjust nutrient concentration according to crop stage or environmental factors.

Uniform nutrient distribution: Every plant receives the same balanced solution.

Time and labor savings: Automation reduces manual mixing and spreading work.

Reduced waste: Less fertilizer runoff or evaporation, protecting the environment.

Higher yield and quality: Plants absorb nutrients more efficiently, improving growth and harvest consistency.

For growers who value efficiency and sustainability, installing a greenhouse liquid fertilizer equipment system is a long-term investment that pays off in productivity and quality.

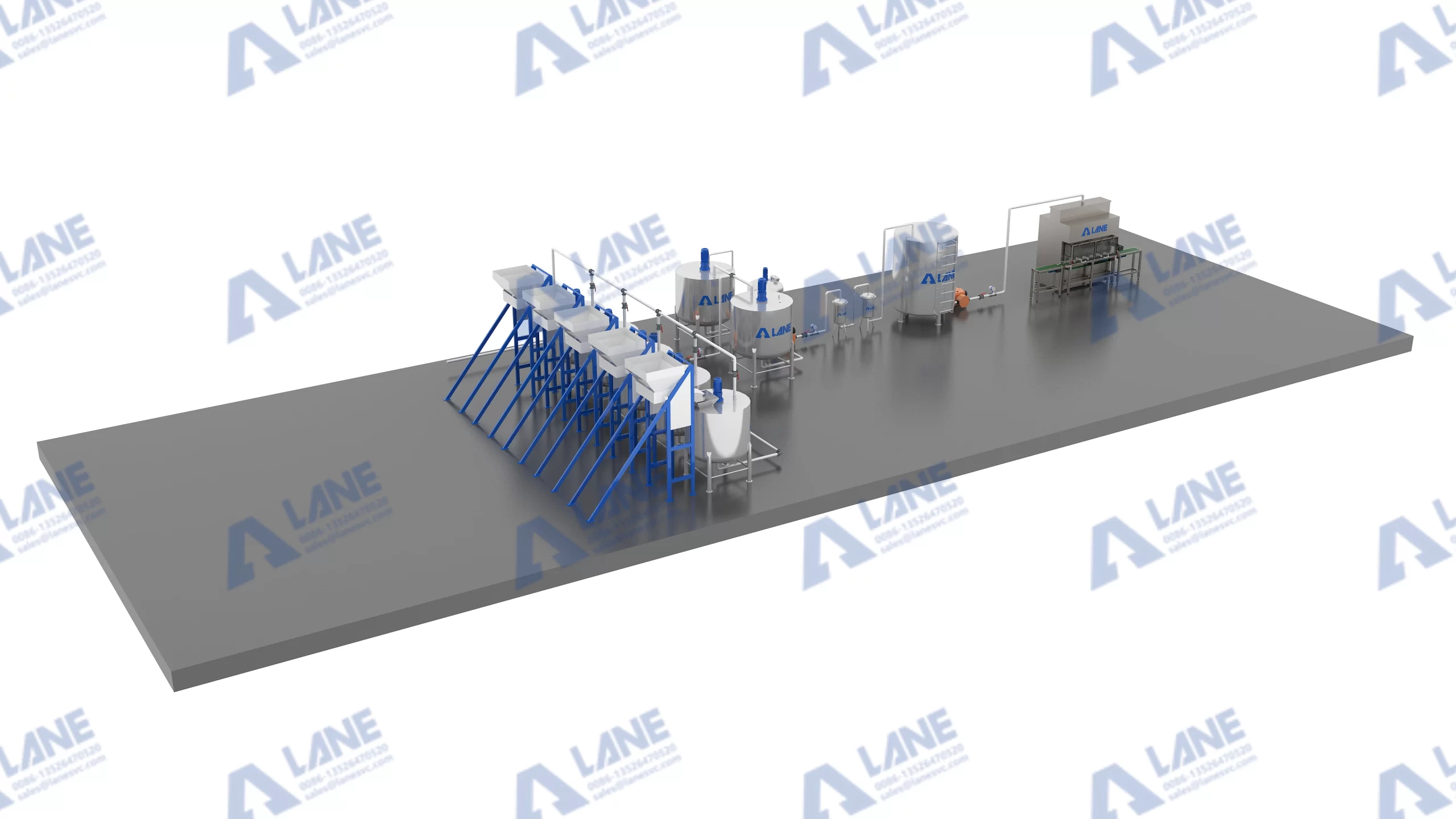

A complete greenhouse liquid fertilizer equipment setup typically includes several interconnected machines, each responsible for a specific stage of fertilizer preparation and distribution.

Below is a breakdown of the main components:

| Stage | Equipment | Function |

| Raw Material Storage | Stainless Steel Storage Tank | Holds urea, potassium nitrate, phosphoric acid, etc. |

| Dissolving & Mixing | Liquid Fertilizer Mixer / Agitator | Ensures all nutrients are dissolved evenly |

| Filtration | Dual Filter Unit | Removes impurities to prevent clogging |

| Homogenization | Inline Homogenizer | Keeps the liquid solution uniform and stable |

| Dosing Control | Fertilizer Dosing Pump / Injector | Precisely injects fertilizer into irrigation lines |

| Distribution | Fertigation Control Unit / Manifold | Delivers fertilizer to plants through irrigation |

| Monitoring System | pH & EC Sensors, PLC Controller | Adjusts nutrient levels and tracks data automatically |

All of these components work together to form an intelligent, automated nutrient delivery system designed for greenhouse environments.

A greenhouse liquid fertilizer production line is designed to automate the entire process of preparing, mixing, and delivering nutrients to plants. It combines precision dosing, real-time monitoring, and automated fertigation, ensuring crops receive balanced nutrition throughout their growth cycle.

Here’s a closer look at how it works step by step:

(1) Raw Material Storage and Preparation

Liquid or water-soluble fertilizers — such as urea, potassium nitrate, and phosphoric acid — are stored in stainless steel tanks. Each nutrient source is kept separate to maintain purity before mixing.

(2) Dissolution and Mixing

When production begins, the system transfers materials into a liquid fertilizer mixer, where powerful agitators dissolve and blend nutrients uniformly. The operator can set the desired nutrient ratios through a PLC control panel or automated recipe.

(3) Filtration and Homogenization

The mixed solution passes through a multi-layer filter and an inline homogenizer, removing particles and ensuring a stable, even concentration. This step is crucial to prevent clogging in drip irrigation or spray systems.

(4) Automatic Dosing and Fertigation

The system’s dosing pumps inject precise amounts of liquid fertilizer into irrigation water. Sensors monitor pH and EC (electrical conductivity) in real time, automatically adjusting the nutrient composition based on plant growth stage or environmental conditions.

(5) Delivery to Plants

The nutrient-enriched water flows through drip or sprinkler lines, reaching every plant evenly. Because nutrients are absorbed quickly through the roots, the result is faster growth, healthier foliage, and better yields.

Overall, the greenhouse liquid fertilizer equipment transforms complex fertilization work into a smart, automated process — saving time, reducing waste, and improving production efficiency for modern greenhouse operations.

LANE Heavy Industry specializes in designing and manufacturing complete greenhouse liquid fertilizer equipment systems, tailored to the unique needs of modern agricultural producers.

LANE’s systems are widely used in vegetable greenhouses, flower nurseries, hydroponic farms, and horticultural parks.

Main Equipment Supplied by LANE

Liquid Fertilizer Mixing Tank (304/316 Stainless Steel) – corrosion-resistant and durable, available in 500L to 10,000L capacities.

Inline Homogenizer – maintains a consistent fertilizer concentration during pumping.

Automatic Dosing Pumps – provide precise nutrient control based on pH and EC feedback.

Filtration System – removes fine impurities to protect irrigation equipment.

PLC Fertigation Control Cabinet – integrates data collection, nutrient formulas, and irrigation scheduling.

Piping and Valves – made of PVC-U or stainless steel for long-term operation.

LANE engineers design every project based on the customer’s greenhouse size, crop type, and production capacity — from 1 ton/hour to 20 tons/hour systems.

Efficient nutrient management is the foundation of successful greenhouse production, and greenhouse liquid fertilizer equipment provides the precision, automation, and sustainability that modern agriculture requires.

From nutrient mixing to fertigation delivery, LANE’s advanced systems help greenhouse farmers save resources, increase yields, and maintain consistent crop quality year-round.

If you are planning to upgrade or build a new greenhouse facility, LANE Heavy Industry can provide a complete solution — from equipment design and installation to training and long-term support.

With LANE, your greenhouse doesn’t just grow crops — it grows smarter, cleaner, and more profitable.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Leave a Comment

Latest Posts

LANE has more than 500 successful cases and is committed to providing customers with first-class solutions, high-end machinery and equipment, and one-stop pre-sales, sales and after-sales comprehensive customer service.