Fish Waste Liquid Fertilizer Production Equipment for Sustainable Agriculture

Fish waste liquid fertilizer production equipment is completely transforming the ways in which aquaculture, seafood processing, and coastal communities handle organic waste. This technology no longer discards fish scraps, internal organs, and processing wastewater; instead, it converts them into nutrient-rich liquid fertilizers, thereby enhancing soil fertility and crop yields. As the demand for organic and sustainable agricultural solutions continues to grow, this production line offers both economic and environmental benefits.

Fish waste liquid fertilizer production equipment refers to a specialized processing line that converts fish processing by-products into liquid organic fertilizers rich in nitrogen, phosphorus, potassium and trace elements. This equipment uses mechanical, chemical and biological processes to decompose and stabilize the fish manure for agricultural use.

Whether you run a seafood plant or operate in aquaculture, installing fish waste liquid fertilizer production equipment means you can turn waste disposal costs into a profitable product line.

| Feature | Benefit to Farmers | Environmental Impact |

| High Nitrogen Content | Stimulates rapid plant growth | Reduces need for synthetic fertilizers |

| Rich in Amino Acids | Improves soil microbiology | Enhances natural nutrient cycling |

| Trace Minerals | Strengthens crop resistance | Supports biodiversity |

| Organic Certification Potential | Attracts premium markets | Promotes eco-friendly farming |

The production process of fish waste liquid fertilizer involves several clear steps to ensure that the final product is rich in nutrients, safe and reliable for agricultural use. The specific formulation may vary depending on the equipment size and automation level, but the general workflow is as follows:

Collection of Fish Waste–Fresh fish scraps, offcuts, and by-products from processing plants or fish markets are gathered promptly to prevent spoilage and nutrient loss.

Grinding and Homogenizing–The collected waste is crushed and blended into a uniform slurry, improving nutrient availability and making the subsequent processes more efficient.

Enzyme or Microbial Treatment–Specialized enzymes or beneficial microorganisms are introduced to break down proteins, fats, and other organic matter into simpler, plant-available forms.

Filtering and impurity removal – Solid particles and large debris are filtered out by the dual filter to ensure that the liquid has uniform fluidity.

Pathogen Sterilization–Heat treatment or pasteurization is applied to kill harmful bacteria and pathogens, improving safety and storage stability.

Nutrient Adjustment–Optional mineral additives or pH adjustments are made to enhance fertilizer performance for specific crops or soil conditions.

Storage and Packaging–The final fish waste liquid fertilizer is stored in sealed stainless steel storage tanks and packed into containers ready for transport and distribution.

By following this workflow, manufacturers ensure that fish waste liquid fertilizer production equipment delivers a high-quality organic product that boosts crop yields and promotes sustainable farming practices.

LANE’s Advantages in Fish Waste Liquid Fertilizer Production Equipment

Choosing LANE means partnering with a company that understands both fertilizer technology and marine waste processing:

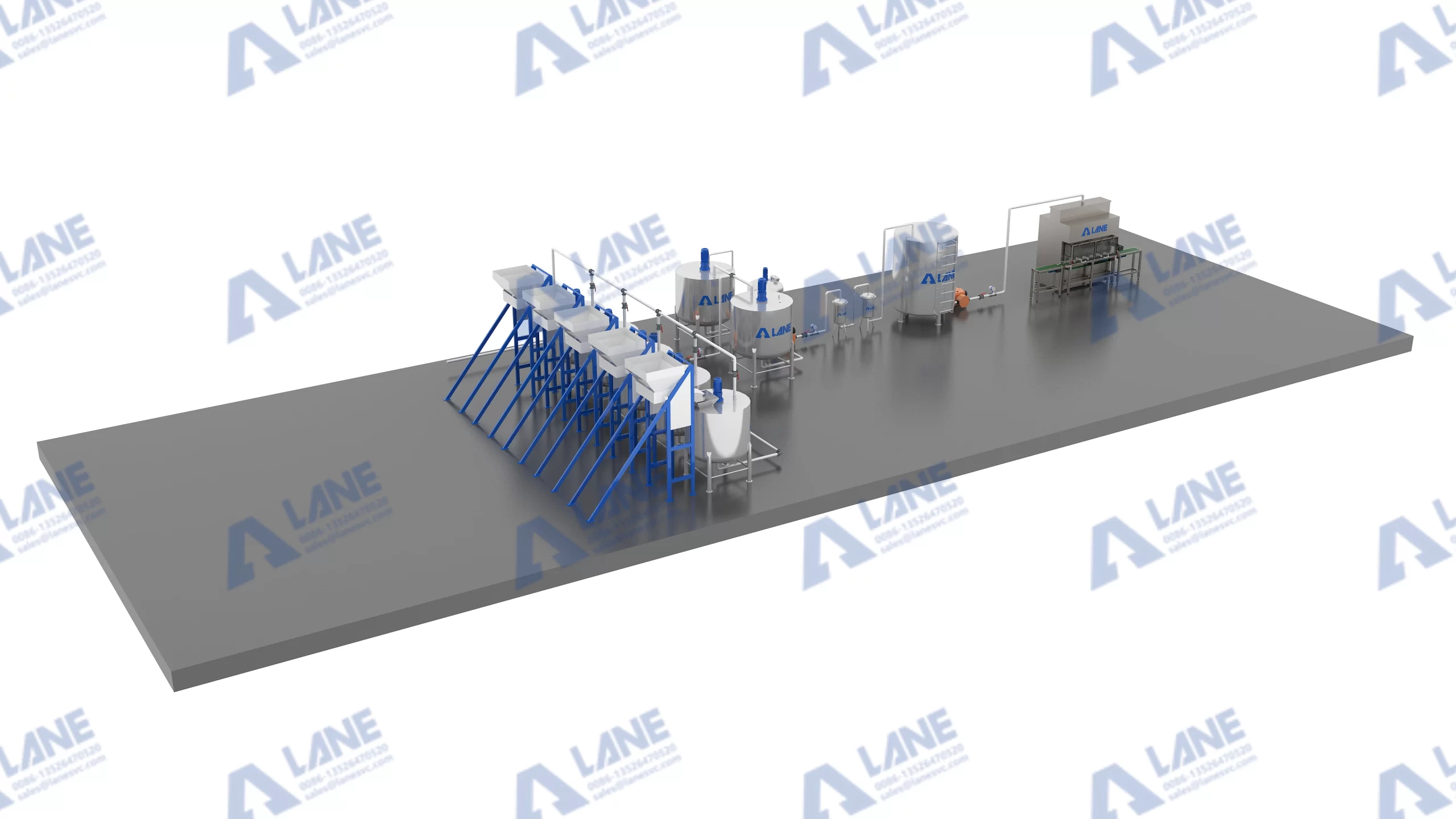

Tailored Solutions – From small coastal plants to industrial seafood processors, we design equipment layouts based on your production capacity and space.

High Efficiency – Advanced hydrolysis tanks and oil separators reduce processing time while preserving nutrient content.

Hygienic & Durable Materials – All components in contact with fish waste are made of food-grade stainless steel, preventing contamination and rust.

Energy-Saving Systems – Optimized heating and mixing systems reduce energy consumption by up to 20%.

Comprehensive Support – From installation to operator training and after-sales service, LANE ensures smooth, profitable operations.

A small fishing village once faced environmental problems – tons of fish waste accumulated over time, not only attracting pests but also emitting a foul smell. The local cooperative decided to invest in a fish waste liquid fertilizer production equipment line from LANE.

LANE’s customized equipment quickly converts fish waste into nutrient-rich liquid fertilizer. Local farmers began using it on their crops and reported that the plants were healthier and produced higher yields. What was once a troublesome problem has turned into a lucrative product, which is sold to the nearby agricultural communities.

Within a year, this town not only solved the problem of garbage disposal, but also created new sources of income, transforming environmental issues into a sustainable economic driver.

The shift toward circular economy models means industries must find ways to turn waste into value. Fish waste liquid fertilizer production equipment does exactly that—transforming discarded byproducts into an eco-friendly, marketable product that benefits farmers, the environment, and the economy.

LANE’s innovative systems combine efficiency, durability, and environmental responsibility, making them the go-to choice for businesses ready to embrace sustainable growth. Investing in this equipment is not just about processing waste—it’s about securing a profitable, greener future. With rising global demand for organic farming solutions, early adopters can position themselves ahead of competitors. Now is the time to turn waste challenges into long-term business opportunities.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Leave a Comment

LANE has more than 500 successful cases and is committed to providing customers with first-class solutions, high-end machinery and equipment, and one-stop pre-sales, sales and after-sales comprehensive customer service.